Golf club head surface composite structure and production method thereof

A golf head and surface compounding technology, which is applied in the field of sports, can solve the problems of good corrosion resistance and wear resistance of golf club heads, inability to have both brittleness and angle adjustment ability on the surface of the ball head with wear resistance, etc. Effect of transition temperature range, easy control operation, high fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1. Golf head SQPQ process technology

[0066] The golf head is processed according to the following process steps to obtain a beautiful appearance, better surface wear resistance and angle adjustment performance and other functions:

[0067] 1. Preheating: The ball head is hoisted into the preheating furnace through the fixture for preheating. Preheating process Preheating at 260°C for 1.5 hours.

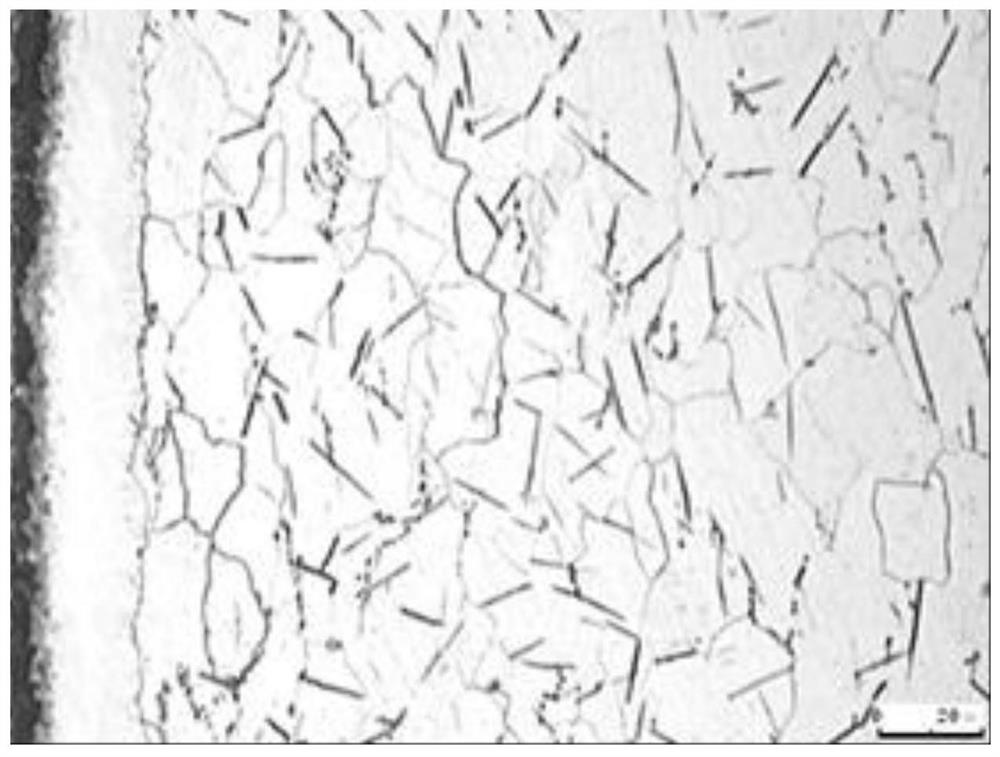

[0068] 2. Nitriding: The ball head is hung into the nitriding furnace through the fixture for nitriding. Nitriding process Nitriding at 590°C for 2.5 hours.

[0069] 3. Oxidation: hoist the ball head into the oxidation furnace for oxidation, oxidation process: oxidize at 350°C for 1.5 hours.

[0070] 4. Cleaning: Hang the ball head into clean water through the fixture to clean it.

[0071] 5. High-frequency diffusion: Local high-frequency treatment is performed on the ball neck of the ball head to dissolve and diffuse the surface nitride layer. The anode volta...

Embodiment 2

[0077] Embodiment 2. Golf head SQPQ process technology

[0078] The golf head is processed according to the following process steps to obtain a beautiful appearance, better surface wear resistance and angle adjustment performance and other functions:

[0079] 1. Preheating: The ball head is hoisted into the preheating furnace through the fixture for preheating. Preheating process Preheating at 350°C for 1.0 hour.

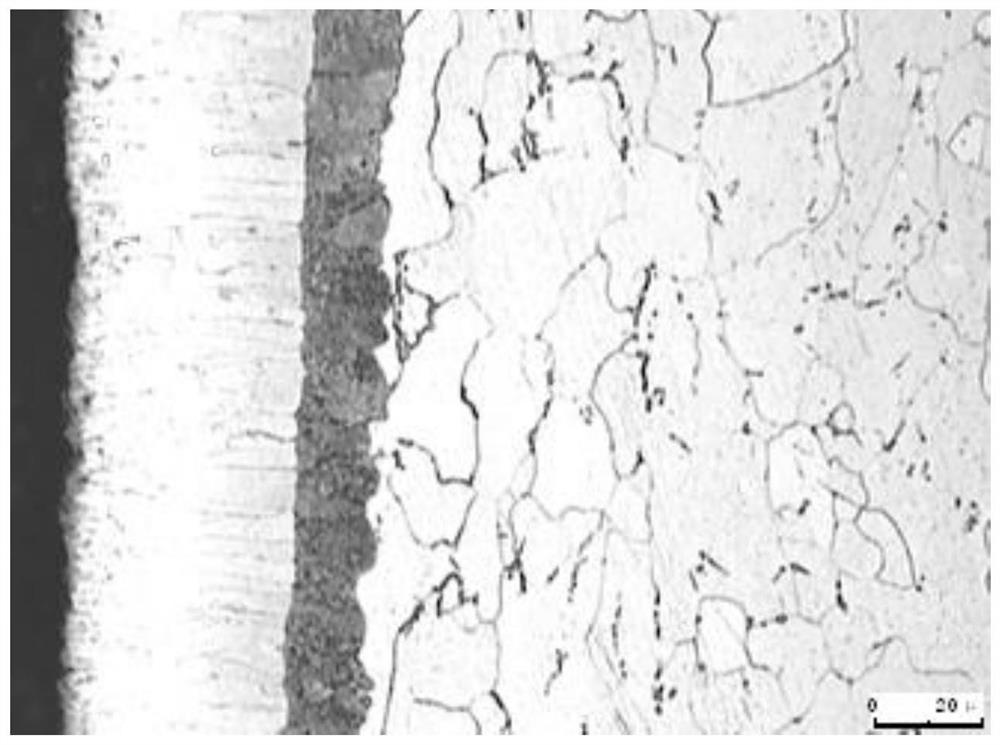

[0080] 2. Nitriding: The ball head is hung into the nitriding furnace through the fixture for nitriding. Nitriding process Nitriding at 620°C for 1.5 hours.

[0081] 3. Oxidation: hoist the ball head into the oxidation furnace for oxidation, oxidation process: 400°C oxidation for 1.0 hours

[0082] 4. Cleaning: Hang the ball head into clean water through the fixture to clean it.

[0083] 5. High-frequency diffusion: Local high-frequency treatment is performed on the ball neck of the ball head to dissolve and diffuse the surface nitride layer. The anode voltag...

Embodiment 3

[0090] Embodiment 3. Golf head SQPQ process technology

[0091] The golf head is processed according to the following process steps to obtain a beautiful appearance, better surface wear resistance and angle adjustment performance and other functions:

[0092] 1. Preheating: The ball head is hoisted into the preheating furnace through the fixture for preheating. Preheating process Preheating at 390°C for 0.5 hours.

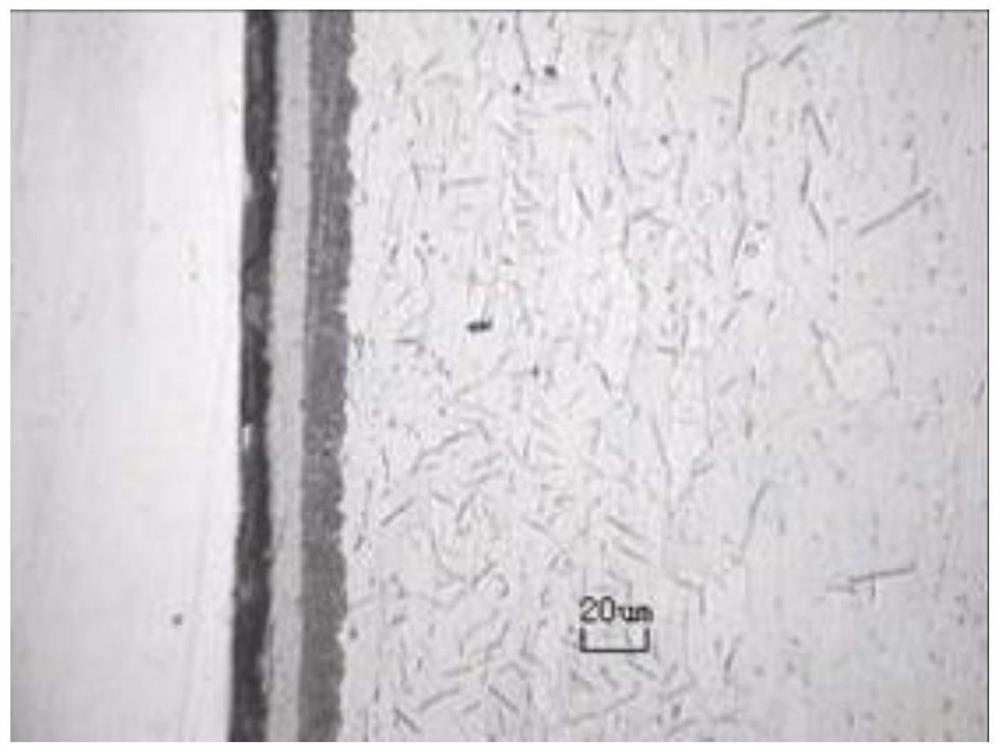

[0093] 2. Nitriding: The ball head is hung into the nitriding furnace through the fixture for nitriding. Nitriding process Nitriding at 650°C for 0.5 hours.

[0094] 3. Oxidation: hoist the ball head into the oxidation furnace for oxidation, oxidation process: 450°C oxidation for 0.5 hours

[0095] 4. Cleaning: Hang the ball head into clean water through the fixture to clean it.

[0096] 5. High-frequency diffusion: Local high-frequency treatment is performed on the ball neck of the ball head to dissolve and diffuse the surface nitride layer. The anode volta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com