Hydrogen sensor of gallium nitride-based high-electron-mobility transistor

A high electron mobility, gallium nitride-based technology, applied in the field of gas sensors, can solve the problems of harsh working conditions, inability to be widely used in various environments, weak output signals, etc., and achieve stable preparation, good performance, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

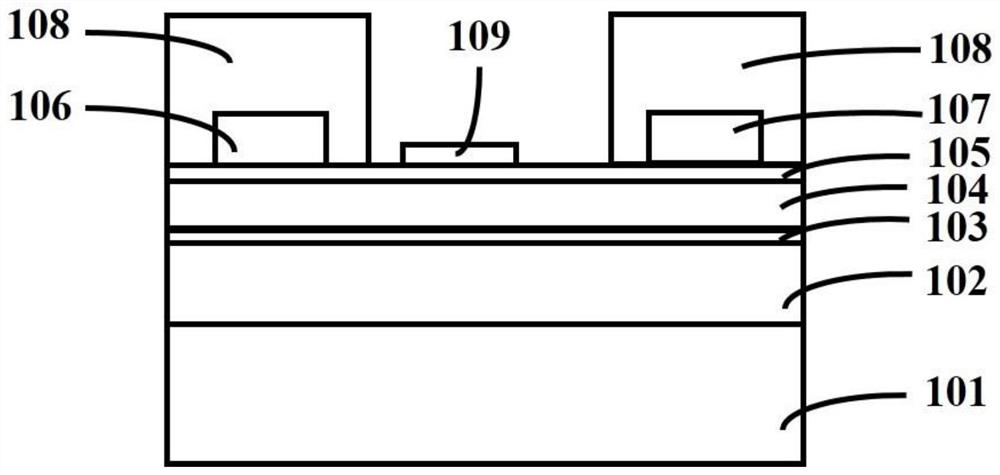

[0021] The HEMT structure used in the present invention is as figure 1 shown, including substrate 101 as Al 2 o 3 layer, 3 μm undoped GaN layer 102, 2 nm AlN intercalation layer 103, Al content 25%, 25 nm thick AlGaN layer 104, 2 nm thick GaN cap layer 105, Ti / Al / Ni / Au source electrode 106 and drain electrode 107, SiO 2 The electrode protective layer 108;

[0022] Specific steps are as follows:

[0023] Step 1: Surface pretreatment of HEMT epitaxial wafers: put the cut epitaxial wafers into acetone solution for ultrasonic cleaning for 10 minutes, take out the epitaxial wafers, put them into absolute ethanol for ultrasonic cleaning for 10 minutes, and then put the epitaxial wafers into deionized water for ultrasonic cleaning Wash for 10 minutes to remove the glue on the surface of the epitaxial wafer and organic matter attached to the surface; then take out the epitaxial wafer and soak it in a dilute hydrochloric acid solution with a volume ratio of 1:10 for 3 minutes to r...

Embodiment 2

[0028] The HEMT structure used in the present invention is as figure 1 shown, including substrate 101 as Al 2 o 3 layer, 3 μm undoped GaN layer 102, 2 nm AlN intercalation layer 103, Al content 25%, 25 nm thick AlGaN layer 104, 2 nm thick GaN cap layer 105, Ti / Al / Ni / Au source electrode 106 and drain electrode 107, SiO 2 The electrode protective layer 108;

[0029] Specific steps are as follows:

[0030] Step 1: Surface pretreatment of HEMT epitaxial wafers: put the cut epitaxial wafers into acetone solution for ultrasonic cleaning for 10 minutes, take out the epitaxial wafers, put them into absolute ethanol for ultrasonic cleaning for 10 minutes, and then put the epitaxial wafers into deionized water for ultrasonic cleaning Wash for 10 minutes to remove the glue on the surface of the epitaxial wafer and organic matter attached to the surface; then take out the epitaxial wafer and soak it in a dilute hydrochloric acid solution with a volume ratio of 1:10 for 3 minutes to r...

Embodiment 3

[0035] The HEMT structure used in the present invention is as figure 1 shown, including substrate 101 as Al 2 o 3 layer, 3 μm undoped GaN layer 102, 2 nm AlN intercalation layer 103, Al content 25%, 25 nm thick AlGaN layer 104, 2 nm thick GaN cap layer 105, Ti / Al / Ni / Au source electrode 106 and drain electrode 107, SiO 2 The electrode protective layer 108;

[0036] Specific steps are as follows:

[0037] Step 1: Surface pretreatment of HEMT epitaxial wafers: put the cut epitaxial wafers into acetone solution for ultrasonic cleaning for 10 minutes, take out the epitaxial wafers, put them into absolute ethanol for ultrasonic cleaning for 10 minutes, and then put the epitaxial wafers into deionized water for ultrasonic cleaning Wash for 10 minutes to remove the glue on the surface of the epitaxial wafer and organic matter attached to the surface; then take out the epitaxial wafer and soak it in a dilute hydrochloric acid solution with a volume ratio of 1:10 for 3 minutes to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com