Anti-corrosion concrete filling base material production device

A production device and concrete technology, applied in clay preparation device, cement mixing device, thin material processing and other directions, can solve the problem of no anti-corrosion concrete, and achieve the effect of avoiding incomplete shredding, avoiding direct falling, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

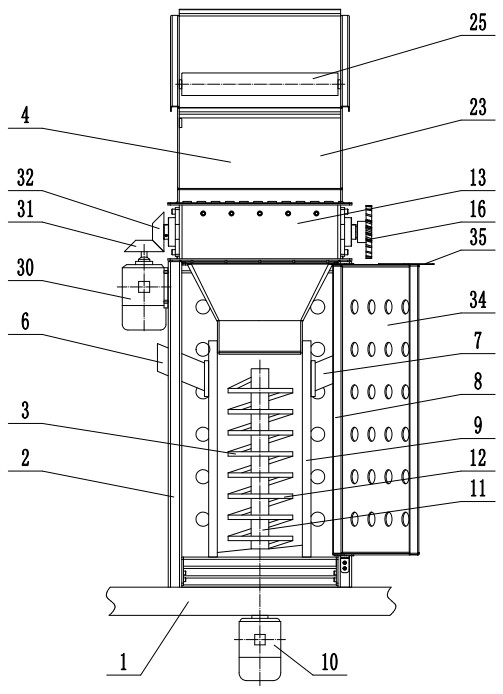

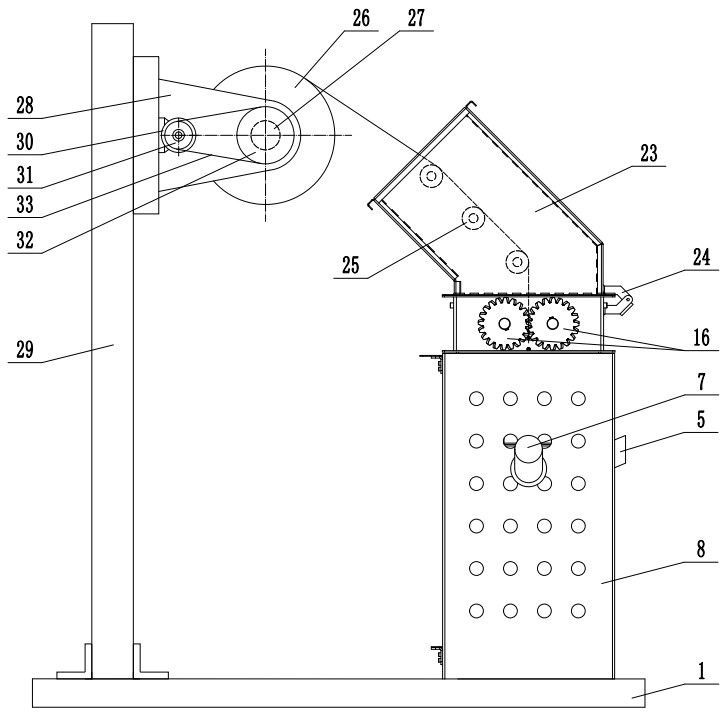

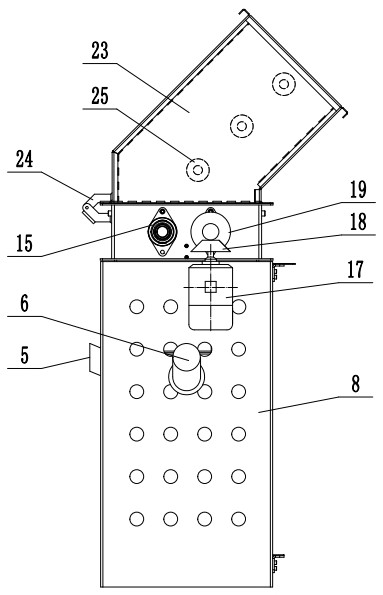

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7As shown, a production device for anti-corrosion concrete filling base material, which includes a production frame platform 1, a filling base material production box assembly 2, a filling base material production assembly 3, a cut glass fiber feeding assembly 4, a kaolin feeding nozzle 5, Asbestos powder feed nozzle 6, expansion agent feed nozzle 7.

[0025] The filling base material production box assembly 2 comprises a filling base material production box body 8, a filling base material production barrel body 9, and the filling base material production box body 8 is installed on the production rack platform 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com