High-strength concrete slurry coating process

A high-strength concrete and concrete technology, applied in the field of concrete, can solve the problems of quicksand and water marks in concrete, decreased wear resistance of concrete, unfavorable concrete, etc., and achieve the effects of reduced bleeding, increased strength, and difficulty in layering and segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-5

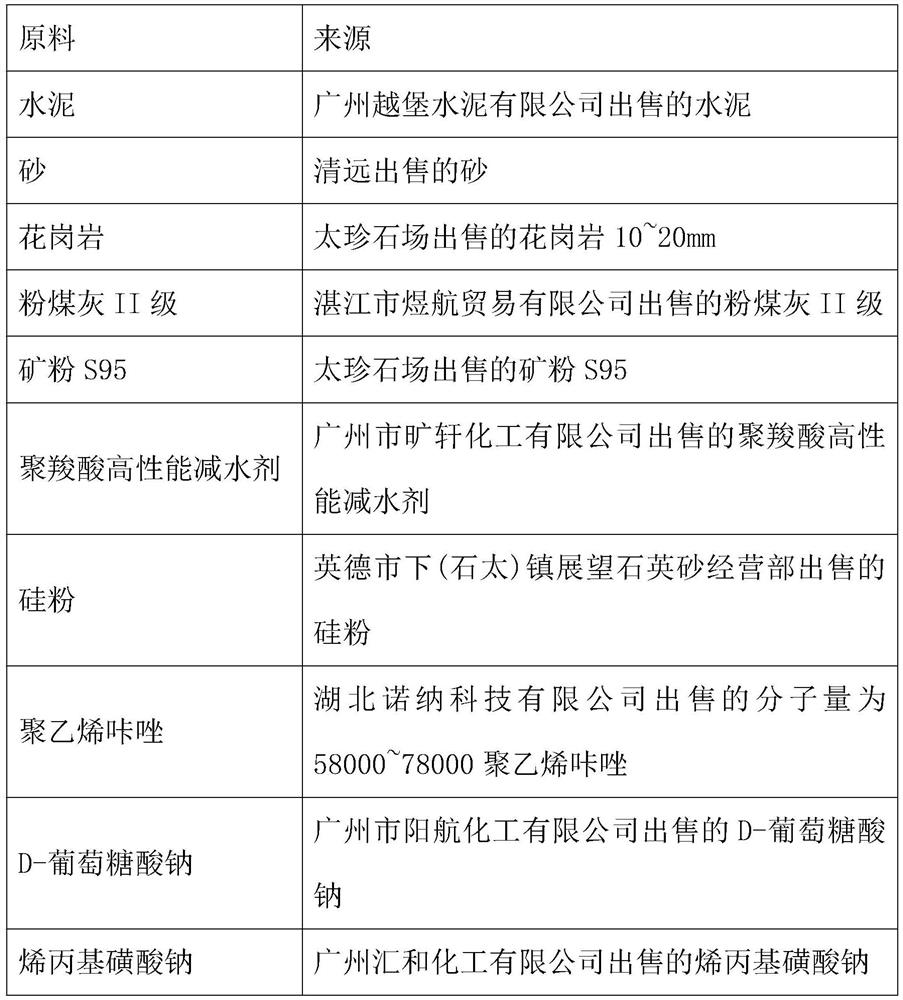

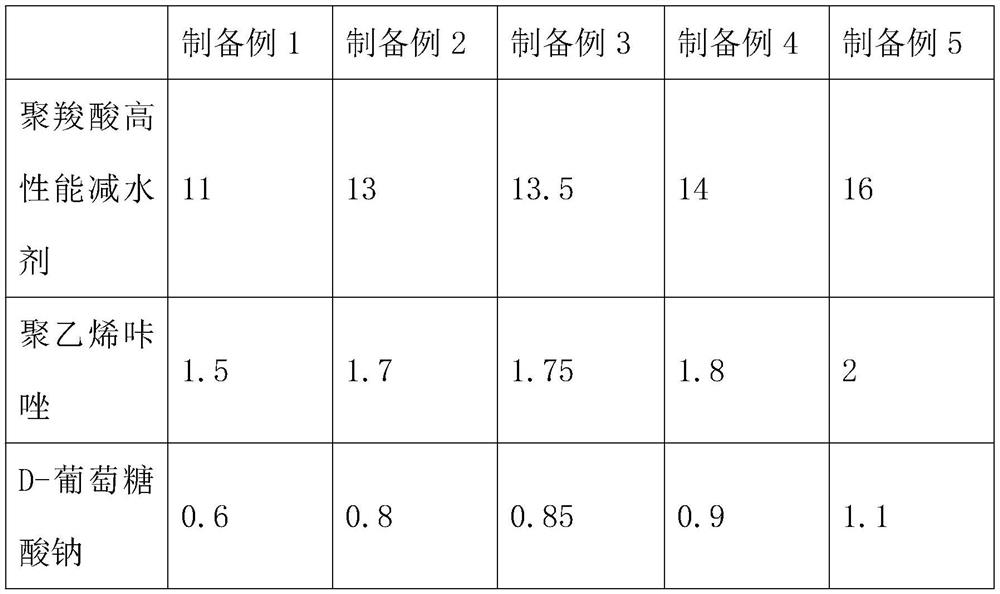

[0046] This preparation example discloses an additive, including the preparation of components in parts by mass in Table 2, unit: Kg.

[0047] Table 2

[0048]

[0049] The preparation method of the additive is as follows: adding polycarboxylate high-performance water reducer, polyvinylcarbazole with a molecular weight of 72500 and sodium D-gluconate into a stirring tank, stirring at a speed of 200 minutes for 12 minutes to obtain the additive.

preparation example 6-9

[0051] The only difference with Preparation Example 3 is:

[0052] Additives also include sodium allylsulfonate 0.5Kg, 0.75Kg, 1.0Kg.

[0053] The preparation method of additive is:

[0054] In the preparation step of the additive, sodium allyl sulfonate and polycarboxylate high-performance water reducer are added into the stirring tank.

preparation example 10

[0056] The only difference with Preparation Example 3 is:

[0057] The molecular weight is 58000 polyvinylcarbazole.

[0058]In the preparation step of the additive, the stirring speed was 150 rpm, and the stirring was carried out for 12 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com