Method for carbonizing surface of sludge compost wood conditioner

A surface carbonization and conditioning agent technology, which is applied in carbon preparation/purification, fertilization equipment, microbial treatment, etc., can solve the problems of oxygen consumption and wood conditioner easy to decompose, so as to increase porosity, reduce adverse effects, increase The effect of water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

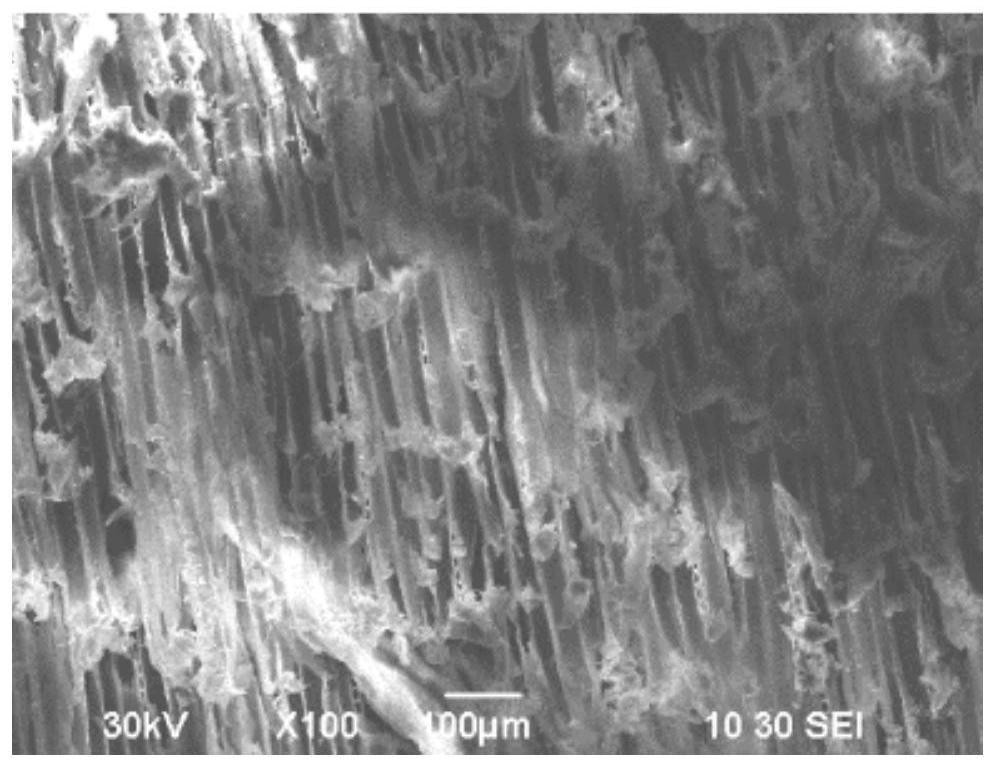

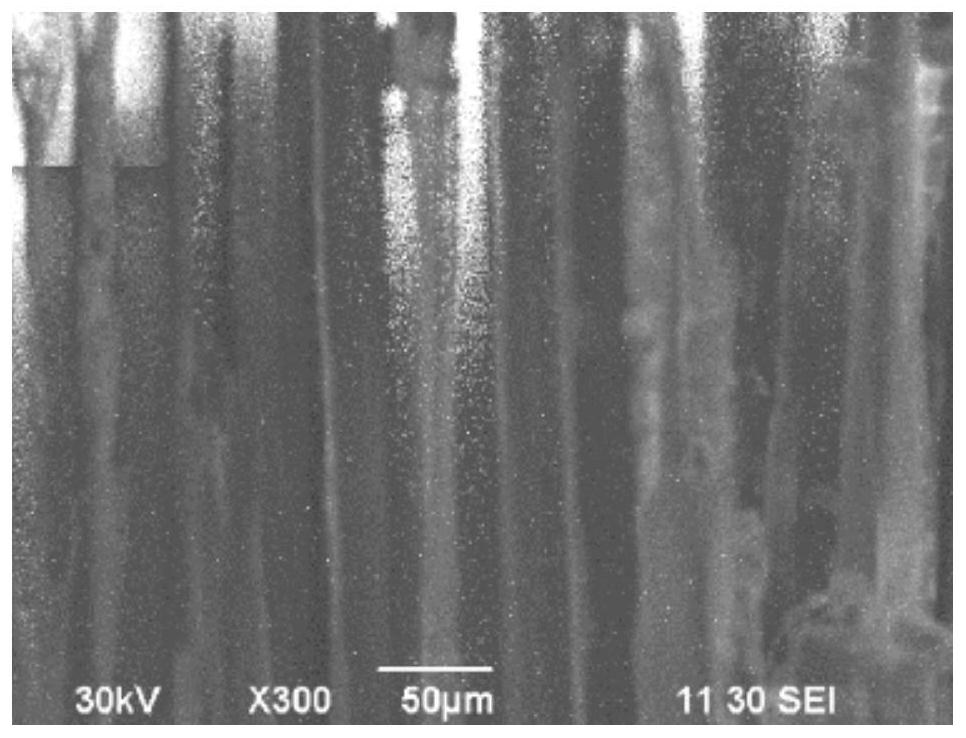

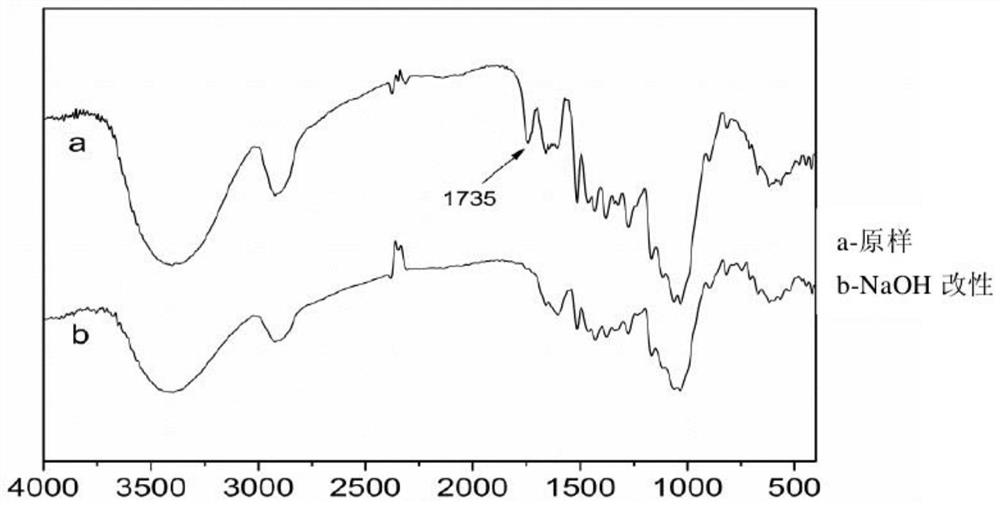

[0022] Embodiment 1: a kind of method of sludge composting wood conditioner surface carbonization, comprises the following steps:

[0023] (1) Pretreatment: configure a sodium hydroxide solution with a mass fraction of 12%, put the sodium hydroxide solution into a heatable airtight container, heat the sodium hydroxide solution to 90°C, and then completely soak the wood conditioner in Sodium hydroxide solution, soaking time is 110min;

[0024] (2) Primary drying treatment: put the wood conditioner treated in step (1) into a drying kiln, and dry the water content of the wood conditioner to 20% under a temperature environment of 70°C for subsequent use;

[0025] (3) Secondary drying treatment: the wood conditioner after step (2) is processed to continue to be dried, and the temperature in the drying kiln is kept at 130° C., and the wood conditioner is applied to the ultrasonic wave with a frequency of 60KHz to process, until the water content of the wood conditioner is dried to ...

Embodiment 2

[0028] Embodiment 2: a kind of method of sludge composting wood conditioner surface carbonization, comprises the following steps:

[0029] (1) Pretreatment: configure a sodium hydroxide solution with a mass fraction of 15%, put the sodium hydroxide solution into a heatable airtight container, heat the sodium hydroxide solution to 95°C, and then completely soak the wood conditioner in Sodium hydroxide solution, soaking time is 120min;

[0030] (2) Primary drying treatment: put the wood conditioner treated in step (1) into a drying kiln, and dry the water content of the wood conditioner to 24% under a temperature environment of 75° C. for later use;

[0031] (3) Secondary drying treatment: the wood conditioner after step (2) is processed to continue to be dried, and the temperature in the drying kiln is kept to be 150° C. at the same time, and the wood conditioner is applied to the wood conditioner with an ultrasonic frequency of 65KHz. until the water content of the wood condi...

Embodiment 3

[0034] Embodiment 3: a kind of method of sludge composting wood conditioner surface carbonization, comprises the following steps:

[0035] (1) Pretreatment: configure a sodium hydroxide solution with a mass fraction of 13%, put the sodium hydroxide solution into a heatable airtight container, heat the sodium hydroxide solution to 93°C, and then completely soak the wood conditioner in Sodium hydroxide solution, soaking time is 115min;

[0036] (2) Primary drying treatment: put the wood conditioner treated in step (1) into a drying kiln, and dry the water content of the wood conditioner to 22% under a temperature environment of 73°C for subsequent use;

[0037] (3) Secondary drying treatment: the wood conditioner after step (2) is processed to continue to be dried, and the temperature in the drying kiln is kept to be 140° C. at the same time, and the wood conditioner is applied to the ultrasonic wave with a frequency of 63KHz for processing. until the water content of the wood ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com