Finished ammonium nitrate fuel oil explosive charging machine

A technology of ammonium explosive and charging machine, which is applied to explosives and other directions, can solve the problem of a small amount of water in blast holes, and achieve the effects of wide application scene, good waterproofness and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

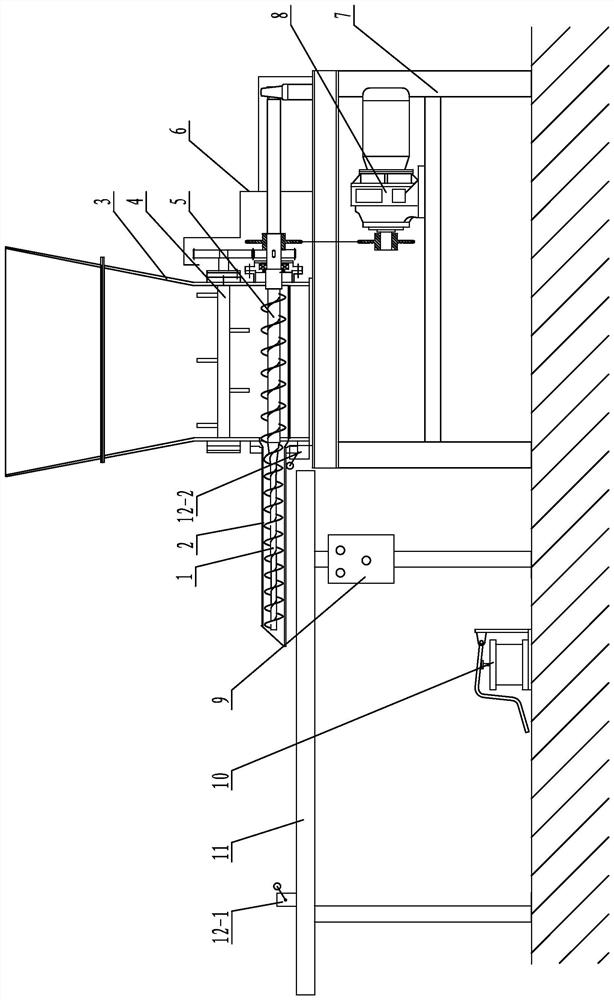

[0018] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

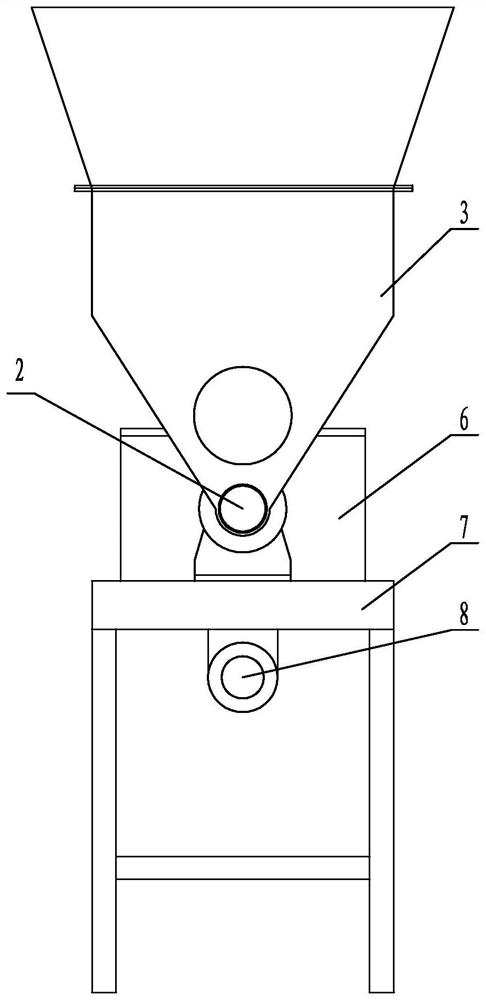

[0019] see figure 1 , figure 2 , a finished ammonium oil explosive charging machine, including a control box 9 and a drug supply device, the drug supply device forms a continuous delivery of drug supply through a drug delivery screw 5, and a charging screw 1 is connected to the outlet end of the drug delivery screw 5 , the charge screw 1 is coaxially fixedly connected with the drug delivery screw 5, the charge screw 1 is located in the charge cartridge 2, the charge cartridge 2 is suspended above the workbench 11, and the workbench 11 is provided with a travel switch 12-1, The travel switch 12-1 is electrically connected with the control box 9;

[0020] Wherein, the charging screw 1 and the drug delivery screw 5 form a screw connection structure through screw fit. The drug supply de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com