Plasma-etching-resistant granulated yttrium oxide for hot spraying and preparation method thereof

A technology of ion corrosion and yttrium oxide, which is applied in the field of thermal spraying, can solve the problems of uneven plasma corrosion resistance of thermal spraying coatings, uneven thickness of thermal spraying coatings, and influence on powder stability, so as to improve energy utilization rate, Uniform plasma corrosion resistance and stable supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

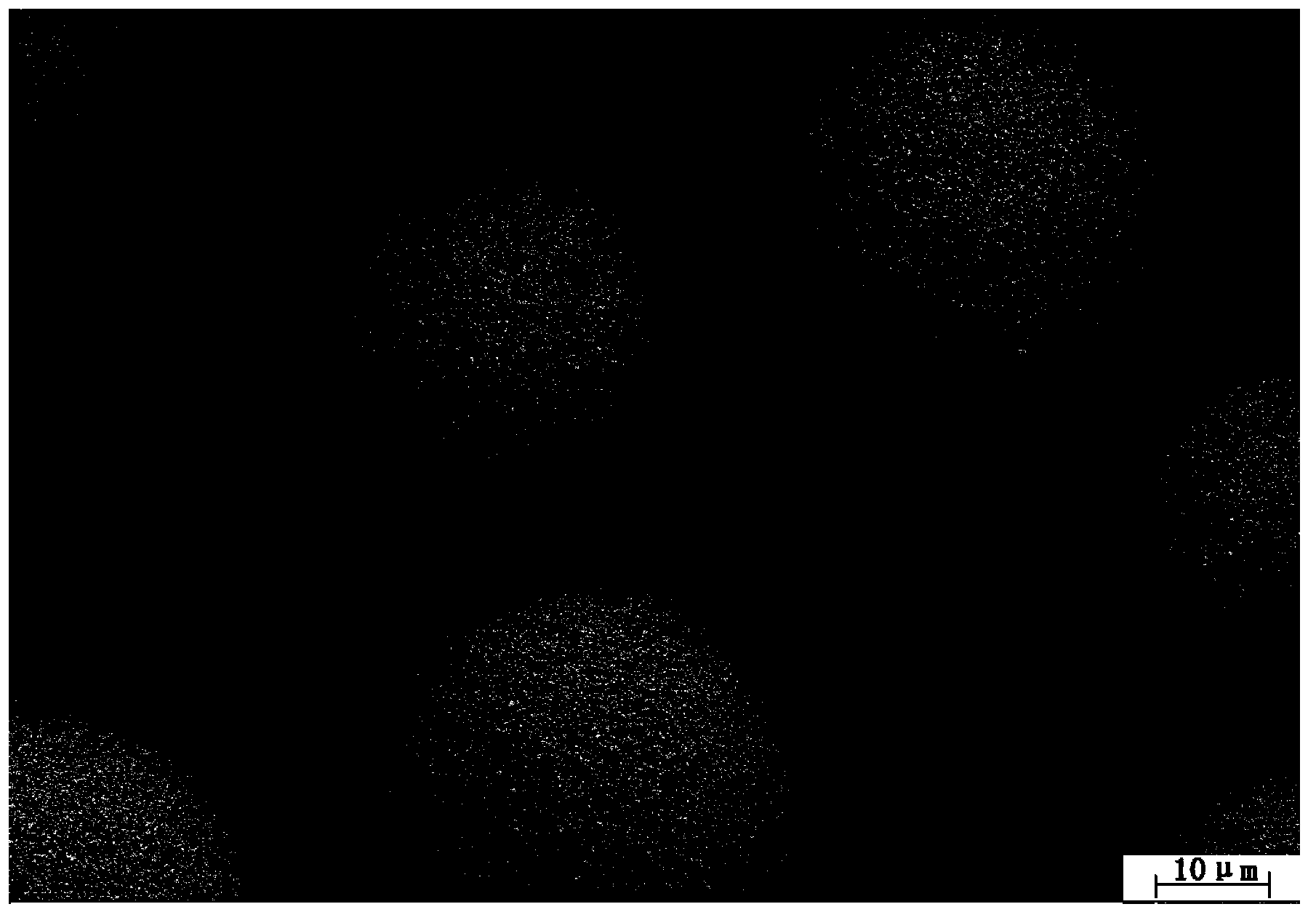

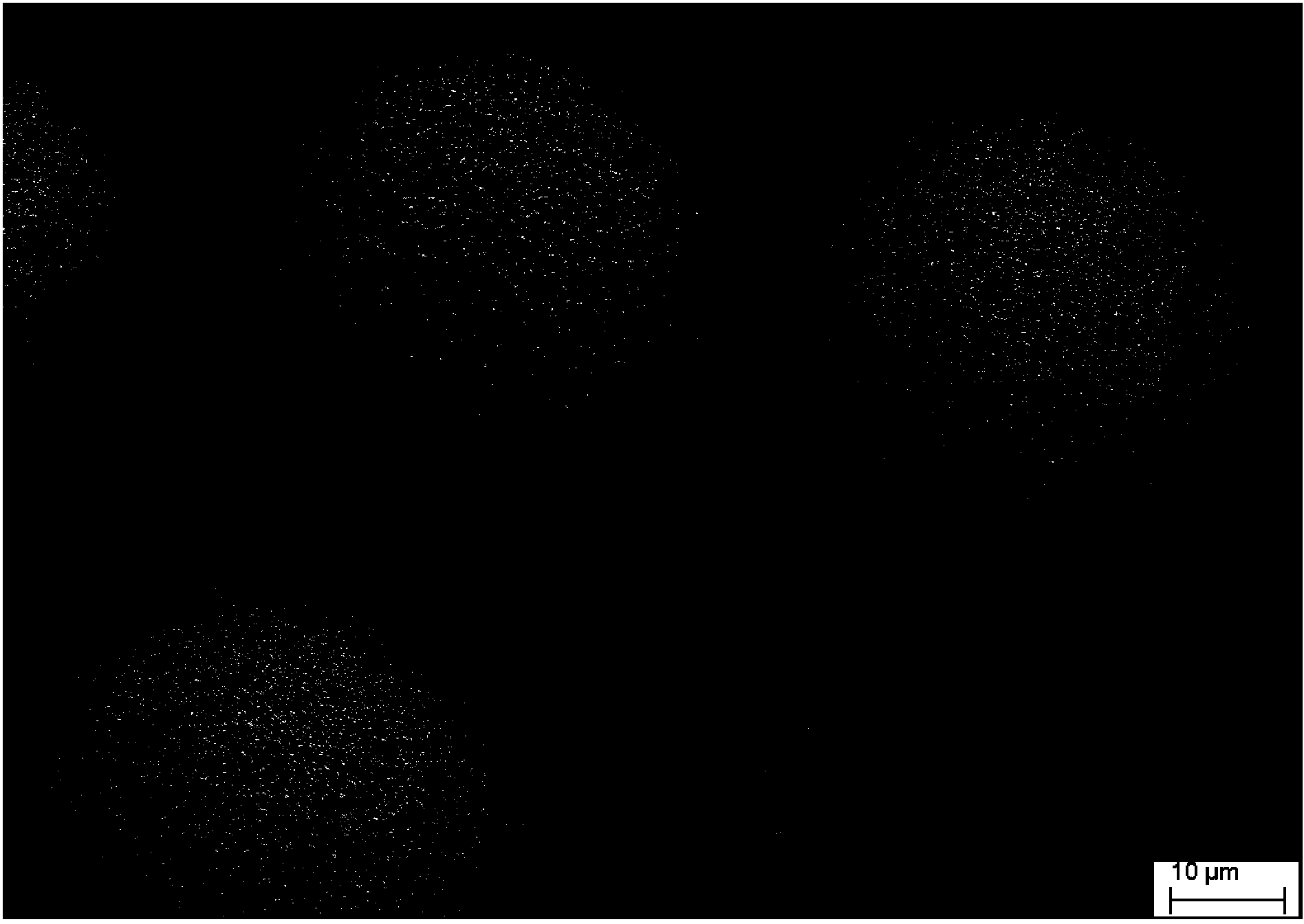

Image

Examples

Embodiment 1

[0032] A preparation method of granulated yttrium oxide for plasma corrosion-resistant thermal spraying of the present invention is carried out according to the following steps:

[0033] (1) Mix 10 kg of yttrium oxide powder with a purity of ≥99.99% and a particle size of 0.2 μm with deionized water at a weight ratio of 1:2, and stir evenly to prepare a slurry;

[0034] (2) inject the slurry into a depolymerization machine for depolymerization and reduction, and the depolymerization time is 30 minutes; the D50 of the slurry after depolymerization is 0.4 μm;

[0035] (3) Stir the slurry after depolymerization and reduction, take 80 g of malic acid crystals and add 160 g of deionized water to fully dissolve it, add it to the slurry, and accelerate the stirring. The pH value of the slurry is 6, and the viscosity is 15 mPa·s;

[0036] (4) Slurry is made into yttrium oxide spherical powder by thermal expansion pelletizing equipment again;

[0037] (5) Perform high-temperature dens...

Embodiment 2

[0040] A preparation method of granulated yttrium oxide for plasma corrosion-resistant thermal spraying of the present invention is carried out according to the following steps:

[0041] (1) Mix 10kg of yttrium oxide powder with a purity of ≥99.99% and a particle size of 0.07um with absolute ethanol at a weight ratio of 1:2, and stir evenly to prepare a slurry;

[0042] (2) inject the slurry into a depolymerization machine for depolymerization and reduction, and the depolymerization time is 30 minutes; the D50 of the slurry after depolymerization is 0.1 μm;

[0043] (3) Stir the slurry after depolymerization and reduction, take 100 g of crystal mixture of malic acid, acetic acid, and oxalic acid (4:3:3 by weight) and add 200 g of deionized water to fully dissolve it, add it to the slurry, and accelerate Stir, the pH value of the slurry is 6, and the viscosity is 17mPa·s;

[0044] (4) Slurry is made into yttrium oxide spherical powder by thermal expansion pelletizing equipment a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com