Processing technology for plastic powder

A processing technology and powder technology, applied in the field of plastic powder processing technology, can solve problems such as stability and poor filling strength, and achieve the effects of improving use characteristics, improving dispersion compatibility and bonding strength, and increasing specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A processing technology for plastic powder, comprising the steps of:

[0039] (1) Crushing treatment:

[0040] Wash the recovered waste plastic first to remove the mud and impurities on the surface, and then crush it for later use;

[0041] (2) pickling treatment:

[0042] Carry out pickling treatment to the waste plastics processed in step (1), take out after completion for subsequent use;

[0043] (3) Drying treatment:

[0044] Place the waste plastics processed in step (2) in a drying box for drying treatment, and take them out for later use after completion;

[0045] (4) Irradiation treatment:

[0046] Carry out irradiation treatment to the waste plastics processed in step (3), after completion, take out for subsequent use;

[0047] (5) Mixed melt extrusion treatment:

[0048] Putting the waste plastic and reinforcing agent treated in step (4) into a twin-screw extruder, and then melt-extruded to obtain a composite material for use;

[0049] (6) Cutting and m...

Embodiment 2

[0061] A processing technology for plastic powder, comprising the steps of:

[0062] (1) Crushing treatment:

[0063] Wash the recovered waste plastic first to remove the mud and impurities on the surface, and then crush it for later use;

[0064] (2) pickling treatment:

[0065] Carry out pickling treatment to the waste plastics processed in step (1), take out after completion for subsequent use;

[0066] (3) Drying treatment:

[0067] Place the waste plastics processed in step (2) in a drying box for drying treatment, and take them out for later use after completion;

[0068] (4) Irradiation treatment:

[0069] Carry out irradiation treatment to the waste plastics processed in step (3), after completion, take out for subsequent use;

[0070] (5) Mixed melt extrusion treatment:

[0071] Putting the waste plastic and reinforcing agent treated in step (4) into a twin-screw extruder, and then melt-extruded to obtain a composite material for use;

[0072] (6) Cutting and m...

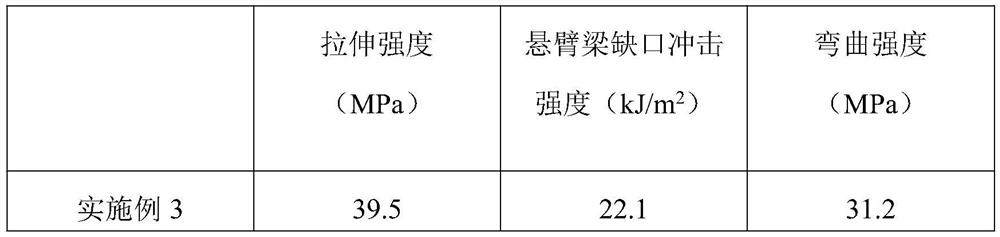

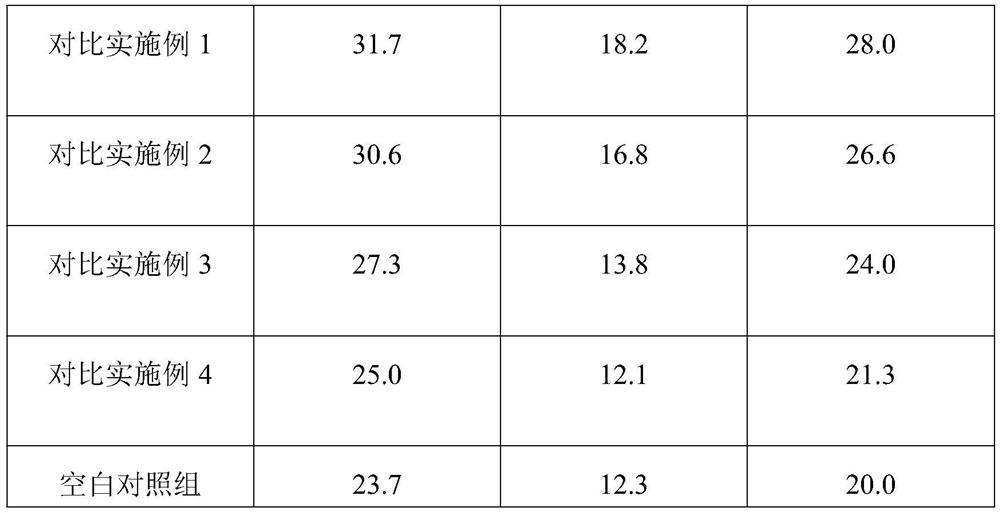

Embodiment 3

[0084] A processing technology for plastic powder, comprising the steps of:

[0085] (1) Crushing treatment:

[0086] Wash the recovered waste plastic first to remove the mud and impurities on the surface, and then crush it for later use;

[0087] (2) pickling treatment:

[0088] Carry out pickling treatment to the waste plastics processed in step (1), take out after completion for subsequent use;

[0089] (3) Drying treatment:

[0090] Place the waste plastics processed in step (2) in a drying box for drying treatment, and take them out for later use after completion;

[0091] (4) Irradiation treatment:

[0092] Carry out irradiation treatment to the waste plastics processed in step (3), after completion, take out for subsequent use;

[0093] (5) Mixed melt extrusion treatment:

[0094] Putting the waste plastic and reinforcing agent treated in step (4) into a twin-screw extruder, and then melt-extruded to obtain a composite material for use;

[0095] (6) Cutting and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com