Embedded pipe type wood structure bearing system

A bearing system and embedded pipe technology, applied in air conditioning systems, building components, heating methods, etc., can solve problems such as the service life of buildings that affect the bearing capacity of bearing columns, prone to cracks and breakage, and hidden safety hazards, and achieve thermal insulation and isolation. Excellent thermal performance, short construction period, and the effect of preventing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the solution of the present invention, the technical solution of the present invention will be further described below in conjunction with specific examples.

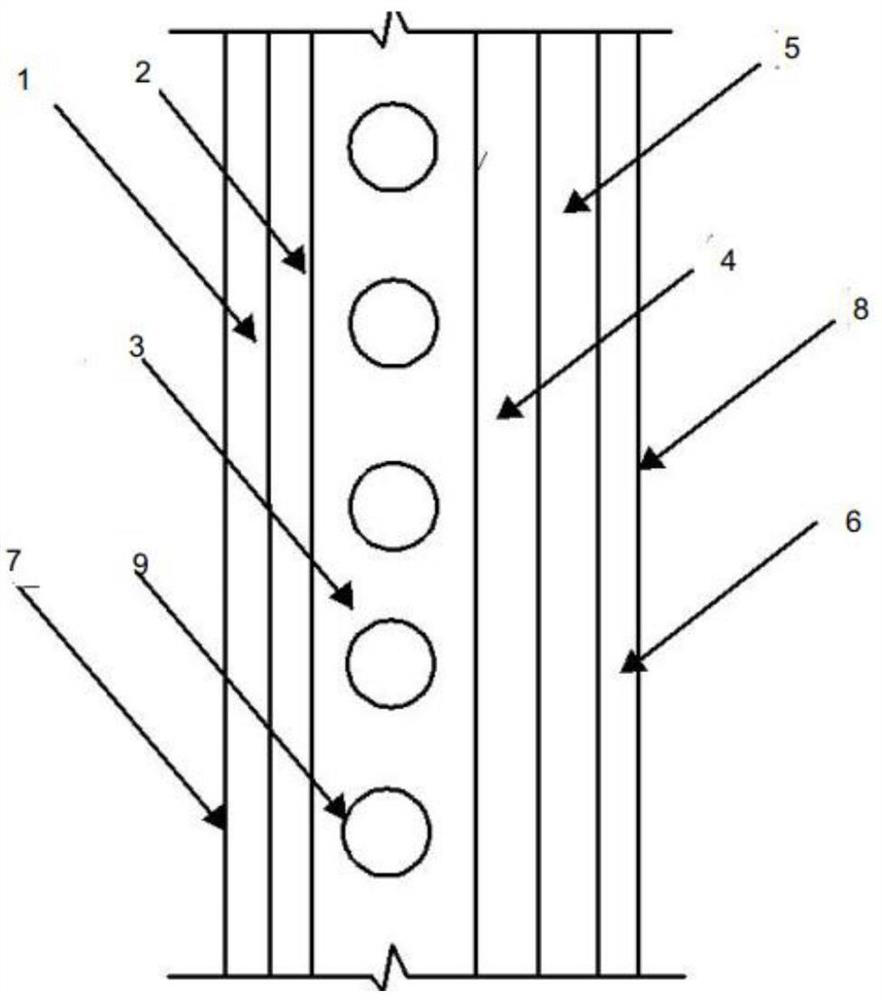

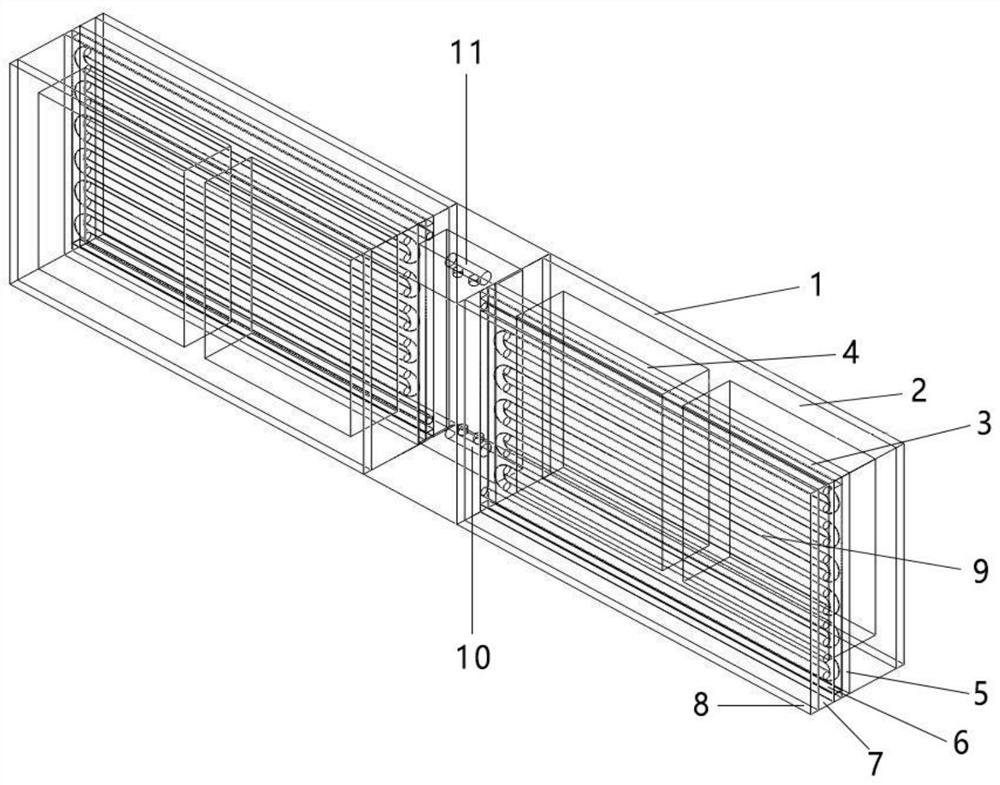

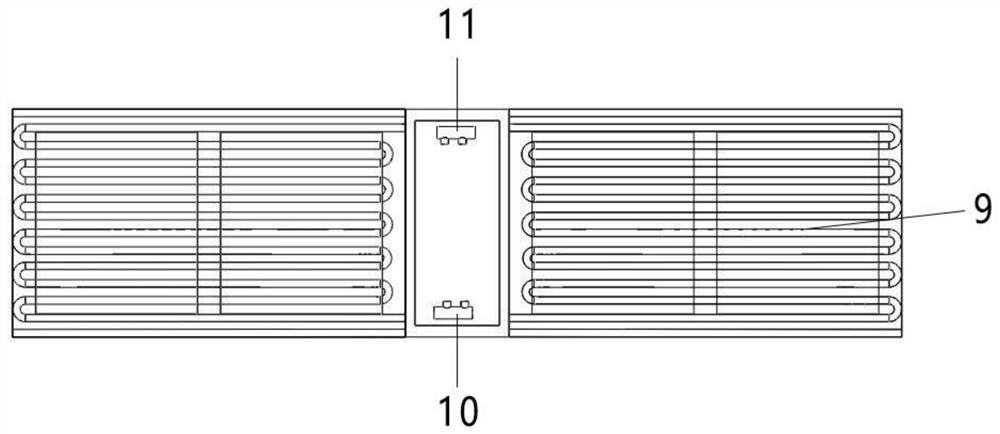

[0023] As shown in the accompanying drawings, an embedded tubular wood structure load-carrying system of the present invention includes multiple sections of embedded tubular walls connected to each other left and right, and each section of the embedded tubular wall is made of outer foam from outside to inside Polyurethane layer 1, outer extruded plastic insulation board layer 2, hollow layer 3, inner extruded plastic insulation board layer 5 and inner foam polyurethane layer 6. In the hollow layer 3, a plurality of wooden keels 4 fixedly connected to the outer extruded insulation board layer 2 are installed at left and right intervals, and each layer can be glued or screwed. A coiled pipe 9 is arranged in the hollow layer, and the coiled pipe is fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com