Undercarriage assembling and detecting integrated equipment

A landing gear and equipment technology, applied in metal processing equipment, measuring devices, instruments, etc., can solve the problems of delivery with defects, heavy workload of repeated handling, and high labor intensity, so as to improve the efficiency of assembly and inspection and avoid manual Effects of recording data and increasing the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

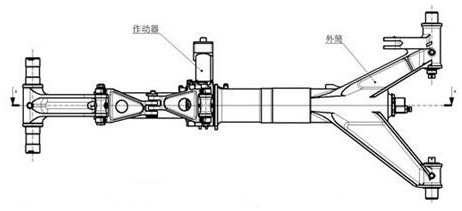

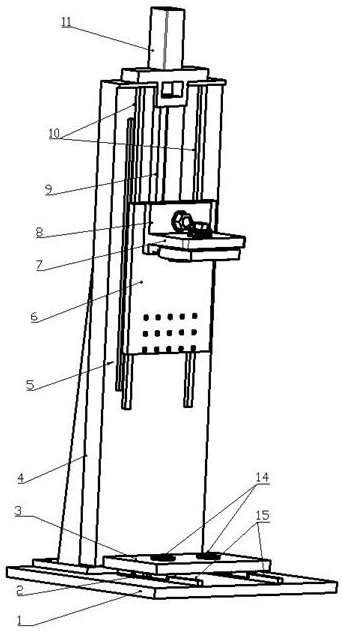

[0043] An integrated equipment for landing gear assembly and testing, such as Figure 1-Figure 6 , including a mechanical system, a measurement system and a control system, the mechanical system includes a base plate 1, a lower workbench 3, a column 4, a slider 6, an upper workbench 7 and a quick-change positioning block 14; the lower workbench 3 is slidably installed On the base plate 1, the column 4 is fixedly installed on the base plate 1, the slider 6 is connected to the front of the column 4 through a screw structure, and the upper workbench 7 and the slider 6 are fixedly connected; There is a quick-change positioning block 14 for quick loading and unloading of the fixture;

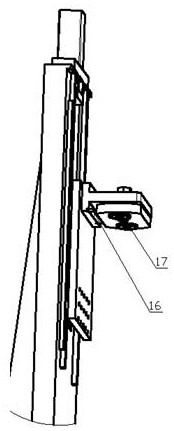

[0044]Described measuring system comprises pull-pressure sensor 12, displacement sensor 16, grating ruler 5 and data processor to form; Described pull-pressure sensor 12 is arranged on slide block 6 or upper workbench 7, and displacement sensor 16 is also arranged on slide block 6 Or on the upper wo...

Embodiment 2

[0062] This embodiment is on the basis of embodiment 1, as Figure 5 , the mechanical system also includes a lower jig J1, an upper jig J2 and a middle jig J3, the lower jig J1 is fixed on the column 4, the upper jig J2 is fixed on the upper workbench 7, and the middle jig J3 is fixed on the slide Block 6 on.

[0063] The structure of the screw mandrel connected between the slider 6 and the column 4 is as follows: the column 4 is provided with a screw mandrel 9 and a guide rail 10, and the slider 6 is provided with a ball nut 13 sleeved on the screw mandrel 9. The slider 6 is sleeved on the guide rail 10 .

[0064] The upper table 7 and the slider 6 are connected by a T-shaped bracket 8, the top surface of the T-shaped bracket 8 is connected to the slider 6 through the first bearing structure, and the lower end surface of the T-shaped bracket 8 is connected by the second bearing structure Connect to Workbench 7.

[0065] The first bearing structure includes a threaded shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com