Comprehensive protection system and method for automatic liquid level measuring device of asphalt reaction kettle

A liquid level measurement device and comprehensive protection technology, applied in the direction of measuring devices, liquid/fluid solid measurement, sampling devices, etc., can solve problems such as unguaranteed, changes in heat dissipation efficiency of radiators, damage to sampling valves and instruments, etc., to improve liquid level Bit measurement accuracy, continuous and stable operation, and precise temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

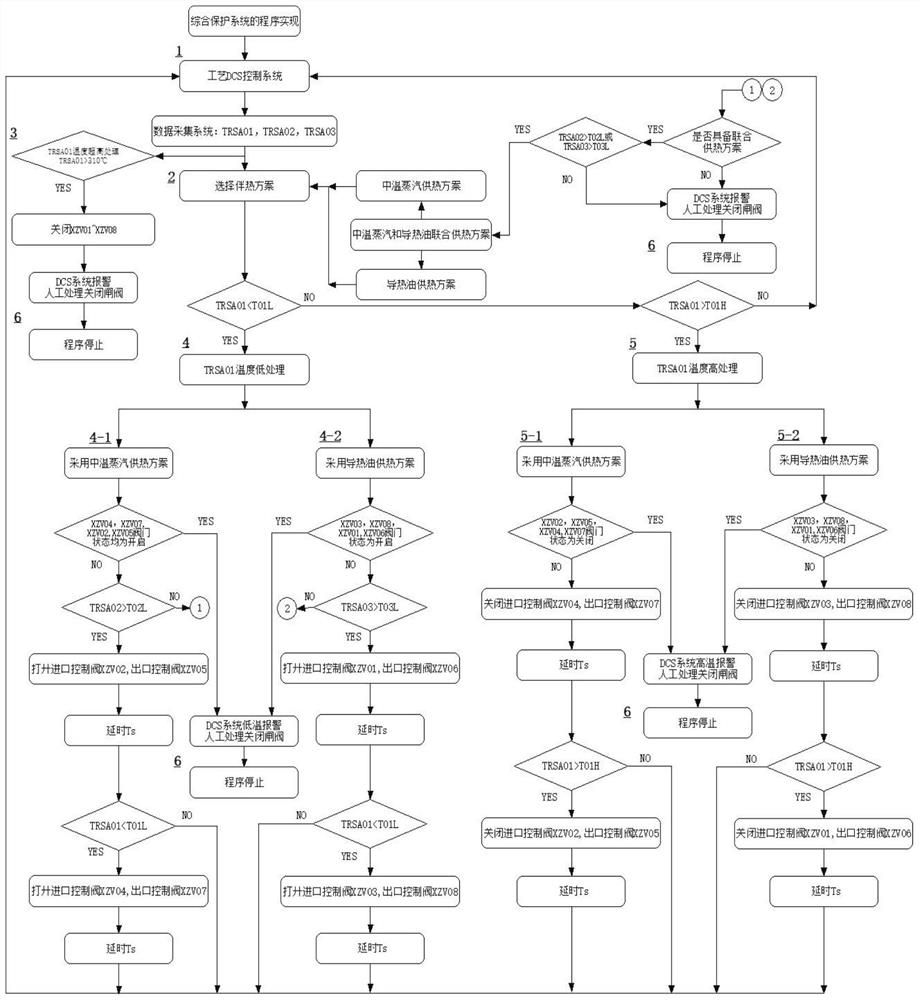

[0065]The specific implementation manners provided by the present invention will be described in detail below with reference to the accompanying drawings.

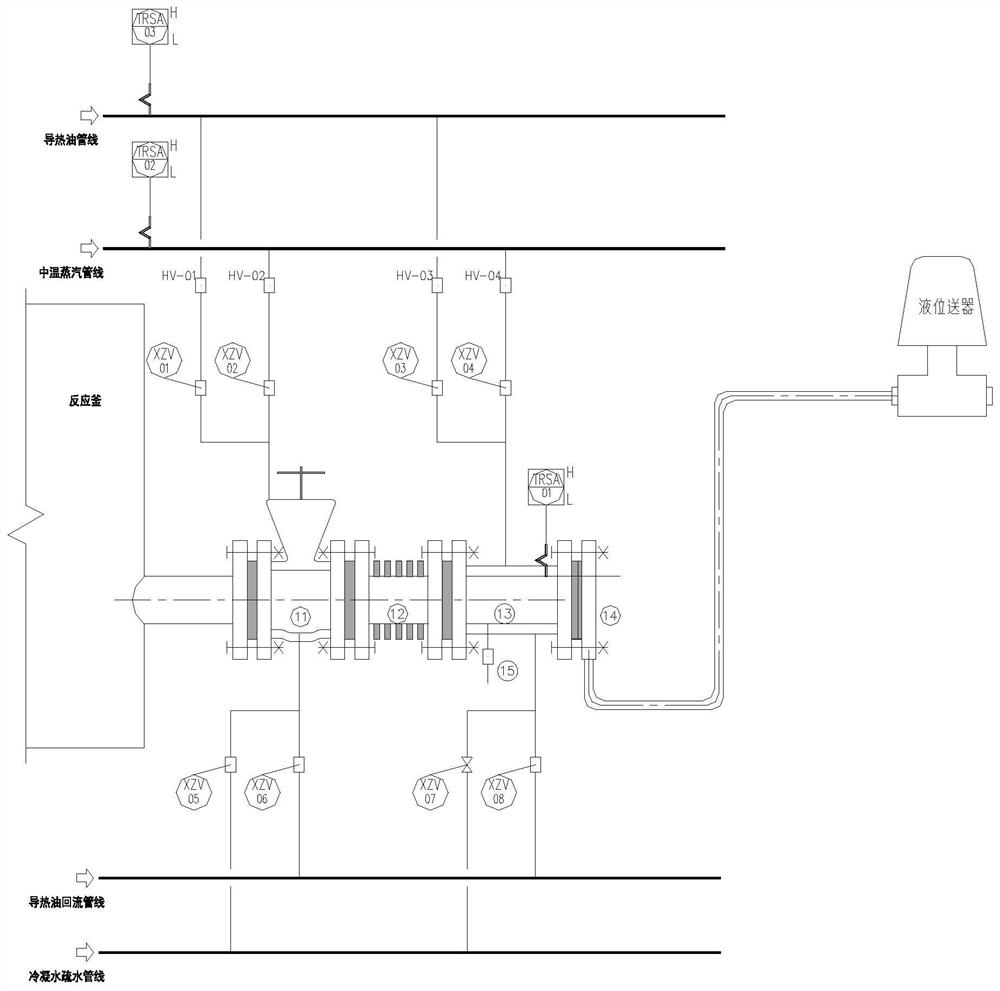

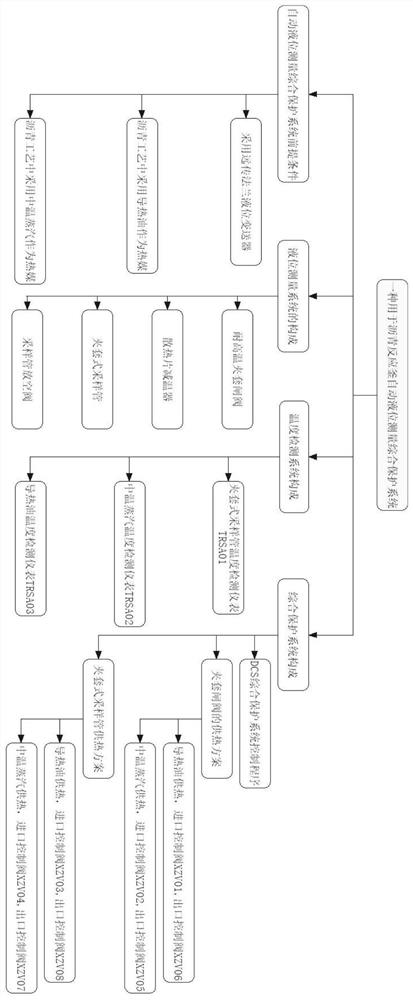

[0066]Such asfigure 1 As shown, a comprehensive protection system for an automatic liquid level measuring device for an asphalt reactor, the liquid level measuring device includes a jacketed sampling pipe 13 and a remote flange liquid arranged on the jacketed sampling pipe 13 The front end of the level transmitter 14 and the liquid level transmitter 14 is also provided with a jacketed gate valve 11.

[0067]The integrated protection system includes a heat-conducting oil pipeline and a medium-temperature steam pipeline, whereby the two-pipe line tracing heat the jacketed gate valve 11 and the jacketed sampling pipe 13 in the liquid level measuring device, and also includes the jacketed The radiator 12 between the gate valve 11 and the liquid level transmitter 14 is used for heat dissipation to reduce the temperature of the high-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com