Method for measuring lip sticking force of tipping paper for cigarettes according to color fastness

A technology for cigarette tipping paper and determination methods, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve problems such as poor reproducibility, inability to strictly quantify results, and no reference to anti-adhesive lips, etc., to achieve reproducibility Enhanced, consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

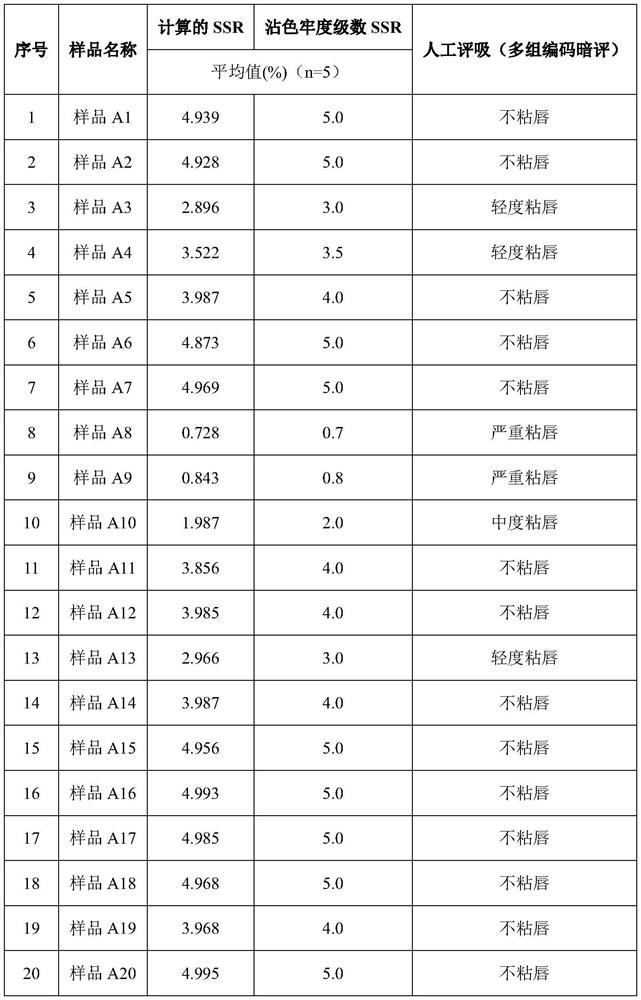

[0031] In this example, 20 different samples were measured by the above method, and tested with the existing manual suction evaluation method, and the test results are shown in Table 2. Among them, the manual evaluation adopts multiple groups of coding and dark evaluation, that is, when the evaluation personnel do not know the contact angle of the sample in advance, the same sample is divided into multiple groups of random codes, and the evaluation personnel evaluate the suction, and give five grades according to the sticky lip situation. : Grade 0, Grade 1, Grade 2, Grade 3, Grade 4; Grade 0 is not sticky to the lips, Grade 1 is mildly sticky, Grade 2 is moderately sticky, and Grade 3 is severe Sticky lips and grade 4 are severe sticky lips.

[0032] Table 2 Staining fastness series SSR and comparison with manual evaluation results

[0033]

Embodiment 2

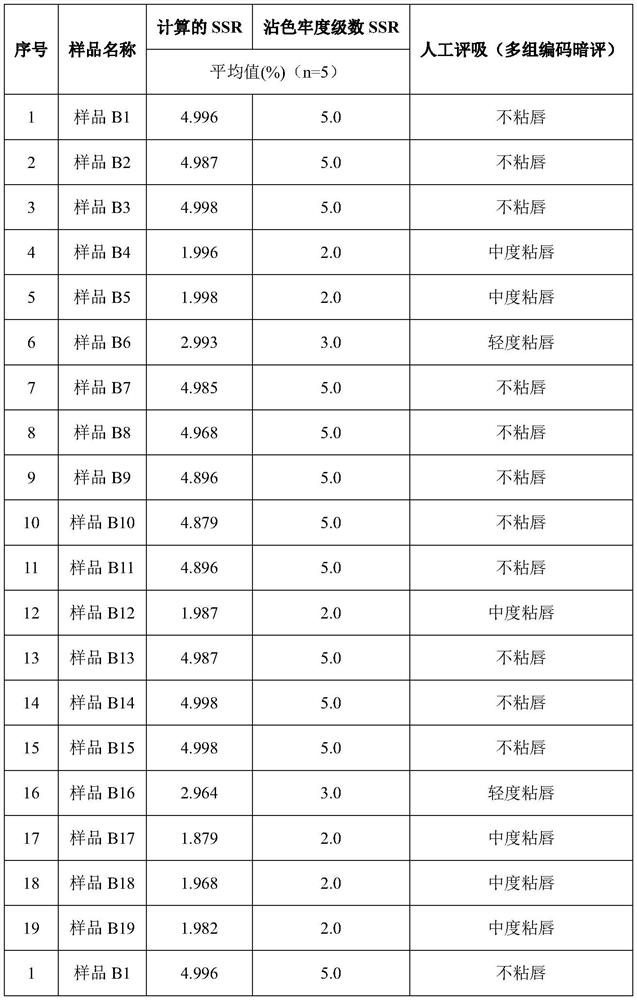

[0035] In this example, 20 different samples were measured by the above method, and tested with the existing manual suction evaluation method, and the test results are shown in Table 3.

[0036] Table 3 Staining fastness series SSR and comparison with manual evaluation results

[0037]

[0038] As can be seen from Table 2 and Table 3, the detection method of the present invention is basically consistent with the detection results of manual suction evaluation. The method of the invention can objectively and accurately quantify whether the cigarette tipping paper has lip sticking force, is easy to popularize and apply, and provides a basis for formulating the standard of cigarette sticking lip sticking force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com