Cigarette and preparation method thereof

A technology of cigarettes and cigarettes, which is applied in the field of cigarettes and their preparation, can solve problems such as easy ignition of other substances, low market acceptance, and peculiar smell of carbon burning, so as to avoid safety risks, protect health, and prevent burn too fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The method for preparing cigarette cigarettes of the present invention is characterized in that it comprises the following steps:

[0065] (1) Obtain ignition section 1, atomization section 2 and inlet section 3;

[0066] (2) The ignition section 1, the atomization section 2 and the inlet section 3 are rubbed together or compounded through the tipping paper 4.

[0067] In a specific embodiment, obtaining the ignition segment 1 includes: cutting, converging, and gathering the tobacco sheet 111; wrapping the tobacco sheet 111 with the first cigarette paper 112 or the cigar outer wrapper, and making the ignition segment 1 by rolling. segment 1.

[0068] In a specific embodiment, the moisture content of the sliced tobacco slices is 15%-20%.

[0069] In a specific embodiment, the equilibrium moisture content of the ignition section 1 is 12%-14%.

[0070] In a specific embodiment, the burning rate of the first cigarette paper 112 or the outer wrapper of the cigar is less...

Embodiment 1

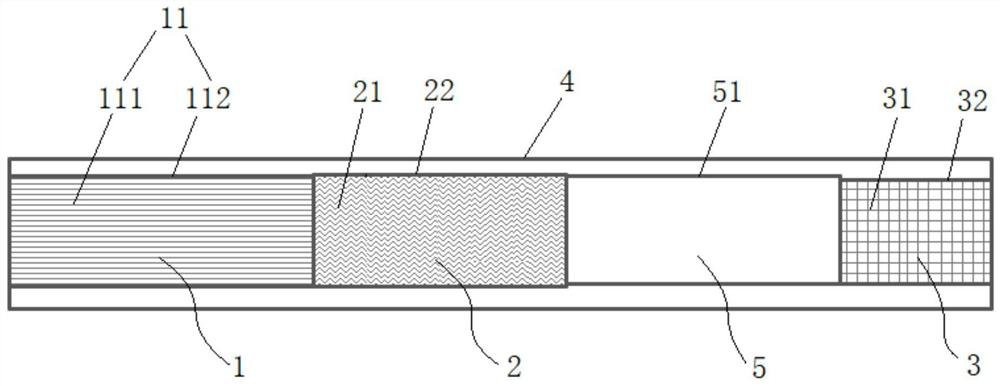

[0079] A cigar-shaped cigarette includes: an ignition section 1 , an atomization section 2 , an inlet section 3 and a conduction section 5 ; Wherein, the length of the ignition section 1 is 5-15 mm, and the diameter is 8-12 mm. The ignition section 1 is formed by curling a cigar core leaf, and the outside of the cigar core leaf is covered with a cigar wrapper. The length of the atomizing section 2 is 10-15 mm. The atomization section 2 includes reconstituted tobacco leaves, and the outside of the reconstituted tobacco leaves is covered with second cigarette paper or composite aluminum paper. Wherein, the reconstituted tobacco leaves contain glycerin and propylene glycol, and the content of propylene glycol is greater than that of glycerin, and the total content of glycerin and propylene glycol is less than 25%. The inlet section 3 includes a cellulose acetate tow section of 5-10 mm, and the outer part of the cellulose acetate tow section is covered with the fourth cigarette ...

Embodiment 2

[0089] The flue-cured cigarette includes: an ignition section 1 , an atomization section 2 , an inlet section 3 and a conduction section 5 ; Wherein, the length of the ignition section 1 is 5-15 mm, and the diameter is 8-12 mm. The ignition section 1 is formed by curling the upper part of flue-cured tobacco leaves with a later identity and more oil content, and the outside of the flue-cured tobacco leaves is covered with the first cigarette paper 112 with a low burning rate (the burning rate is less than 6.0 mm / min). The length of the atomizing section 2 is 10-15 mm. Atomization section 2 includes reconstituted tobacco leaves containing glycerin and propylene glycol (glycerol content 4% to 8%, propylene glycol content 6% to 10%, propylene glycol content is greater than glycerin content), and the outside of the reconstituted tobacco leaves is coated with the second cigarette paper or Composite aluminum paper. The inlet section 3 includes a cellulose acetate tow section of 5-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com