Method and system for improving comprehensive performance of coal-fired power plant boiler SCR system

A technology of SCR system and coal-fired power station, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of increased ammonia escape and large amount of ammonia injection, and achieve the effect of improving comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

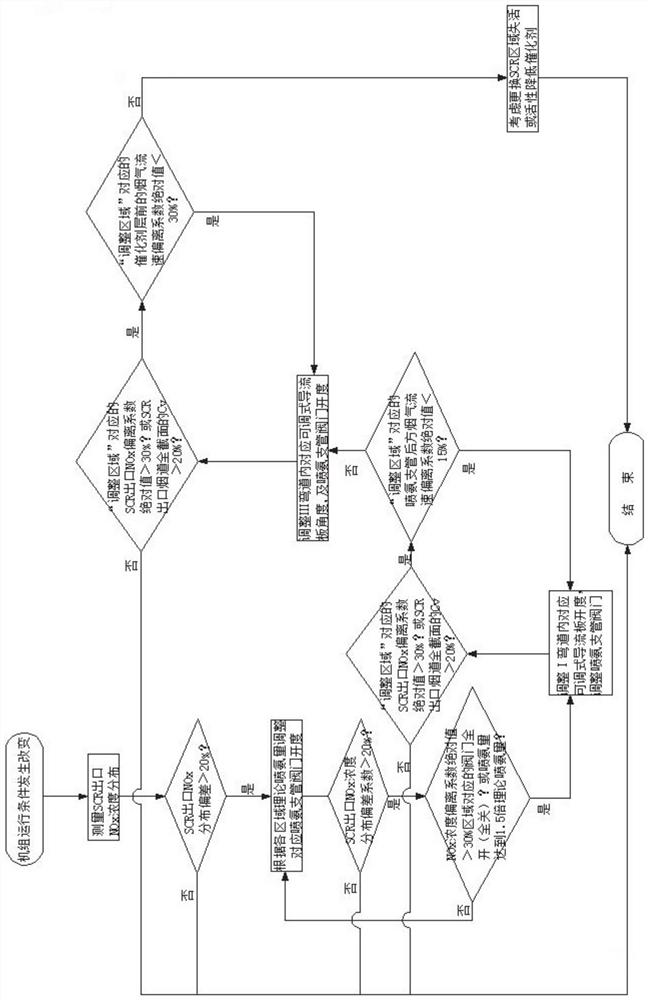

[0047] This embodiment provides a method for improving the overall performance of the SCR system of a coal-fired power plant boiler, such as figure 1 shown, including the following steps:

[0048] 1) Obtain the NOx distribution deviation coefficient of the flue section after the denitration catalyst layer:

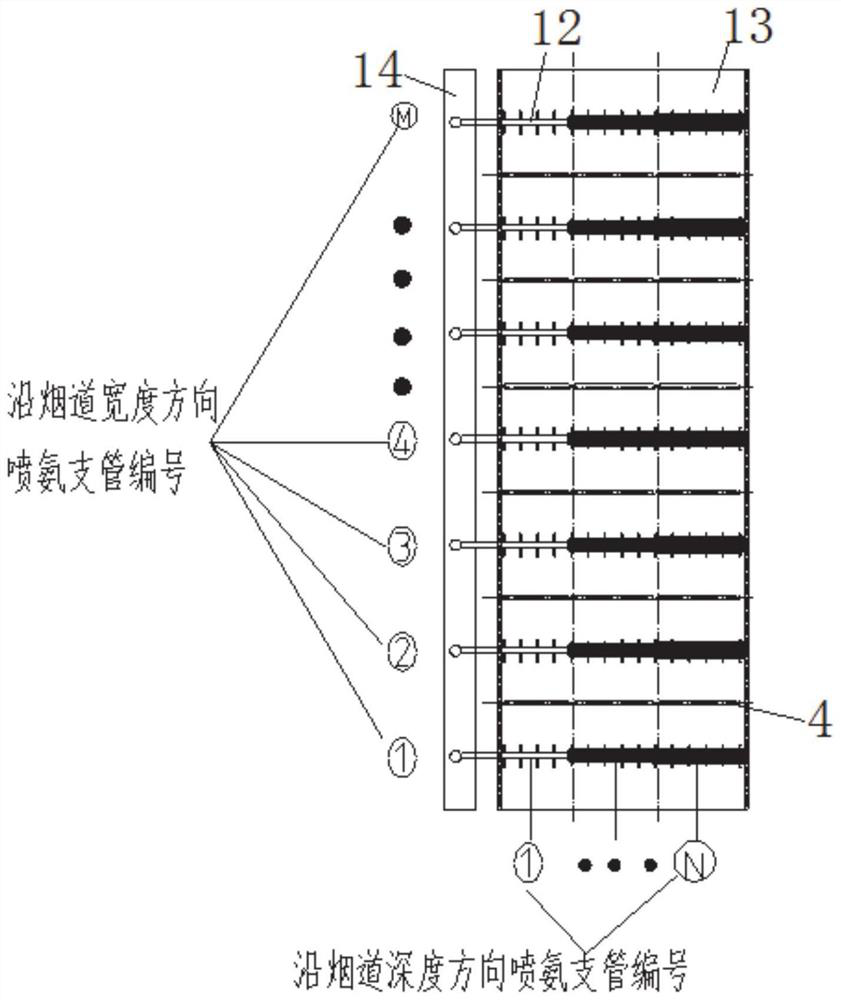

[0049] According to the distribution of upstream ammonia injection grids (assumed to be M×N, M is the number of ammonia injection branch pipes in the width direction of the flue, N is the number of ammonia injection branch pipes in the depth direction of the flue), divide the flue behind the denitrification catalyst layer It is M×N areas, and the NOx and O in each area are measured by the flue gas analysis device 2 ; The NOx distribution deviation coefficient Cv is obtained by calculation. If the deviation is less than 20%, the system does not operate, and if the deviation coefficient>20%, proceed to the next step.

[0050] The formula for calculating the NOx concentrat...

Embodiment 2

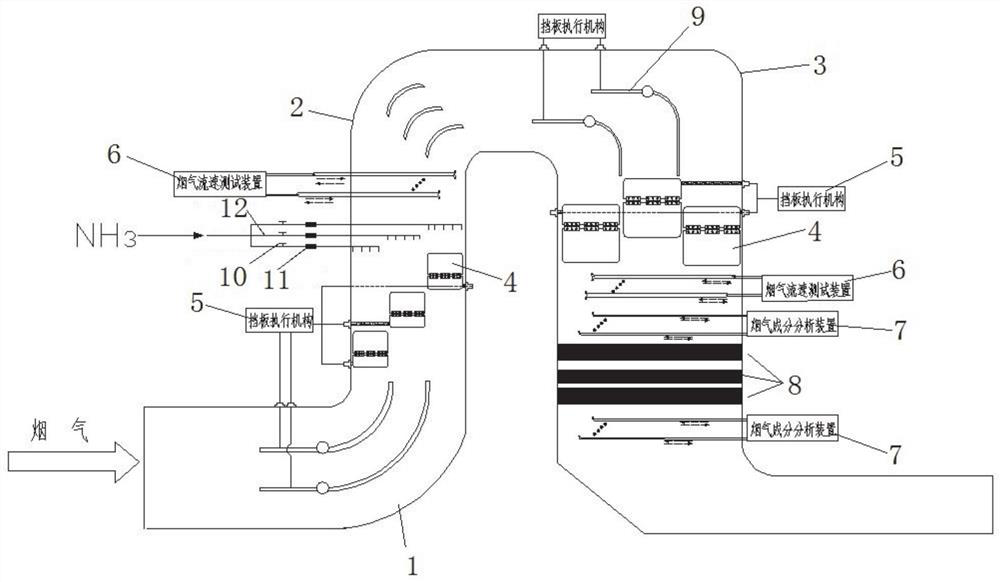

[0080] This embodiment provides a system for improving the comprehensive performance of the SCR system of a coal-fired power plant boiler, which includes a flue 13, an ammonia injection grid arranged in the flue 13, an adjustable deflector device, a flue gas flow rate measuring device 6, and a flue gas flow rate measuring device 6. Gas composition measuring device 7, intelligent control module; the opening and closing angle of the adjustable deflector device and the ammonia injection amount of the ammonia injection grid are controlled by the intelligent control module. Wherein, the adjustable deflector device includes a straight flue combined deflector 4 , a curved combined deflector 9 and its baffle actuator 5 .

[0081] Such as figure 1As shown, the flue 13 is provided with a first bend 1, a second bend 2, and a third bend 3 from the smoke inlet end, between the second bend 2 and the first bend 1, and the third bend 3 They are respectively connected through straight flue. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com