Electric vehicle chassis assembly and mining electric vehicle

An electric vehicle and chassis technology, applied in the direction of electric power unit, power unit, vehicle components, etc., can solve the problems of easily damaged chassis springs, easily damaged springs, etc., to ensure support strength, good anti-rolling ability, excellent anti-rolling ability. The effect of inclination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

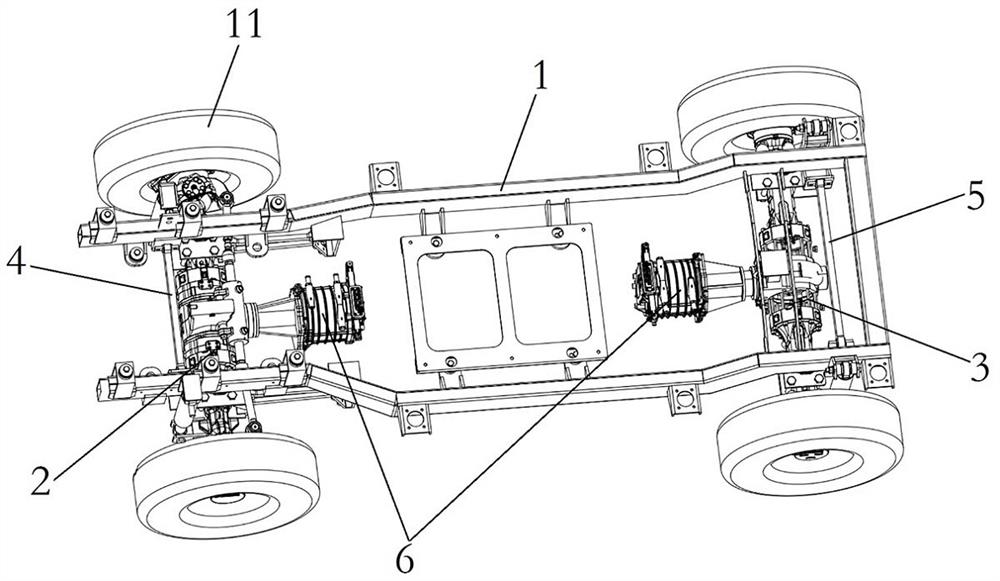

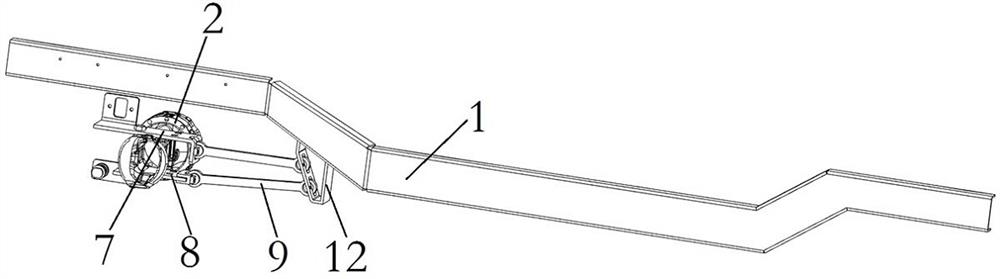

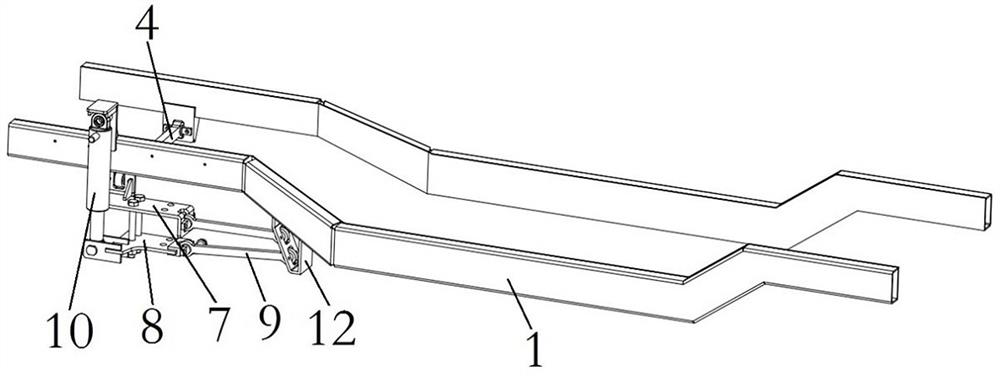

[0052] This embodiment provides an electric vehicle chassis assembly, such as figure 1 As shown, it includes: frame body 1, front axle 2, rear axle 3, first connecting rod 4 and second connecting rod 5; one end of said first connecting rod 4 is hinged with front axle 2, and the other end is hinged with vehicle frame One end of the second connecting rod 5 is hinged with the front axle 2, and the other end is hinged with the vehicle frame; when the vehicle chassis is facing a roll road, when the center of gravity of the vehicle body drives the vehicle frame to move relative to the vehicle wheel axle, through The setting of the first connecting rod 4 and the second connecting rod 5 can realize the pulling force of the front axle 2 or the rear axle 3 on the vehicle frame, provide a force in the horizontal direction for the vehicle frame, reduce the force on the spring, and play a role in the spring. The function of protection makes the electric vehicle chassis assembly have more e...

Embodiment 2

[0067] The mine electric vehicle provided in this embodiment includes the electric vehicle chassis assembly described in Embodiment 1; the mine electric vehicle also has a battery pack, and the battery pack is installed on the main beam of the frame body 1 through a shock-absorbing pad The battery pack supplies power to the drive motor 6 through the battery high-voltage box and the high-voltage distribution box, and manages the output of the battery through the BMS management system. The battery is equipped with an independent water-cooling unit for heat dissipation, and the battery water-cooling unit is arranged at the rear of the vehicle.

[0068] The cab of the mining tram adopts integrated molding technology. The body adopts square steel frame and iron plate skin structure. The interior of the cab is made of black soft interior. Each rear door adopts a fully enclosed structure.

[0069] The whole vehicle is powered by a new energy battery pack plus a travel motor and a hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com