Preparation method of high-strength composite modified emulsified asphalt

A composite modified asphalt and composite modification technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of accelerating the demulsification speed of emulsified asphalt, insufficient shearing and durability, and enhancing emulsified asphalt. Restore the effect of enhancing original properties, reducing looseness and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

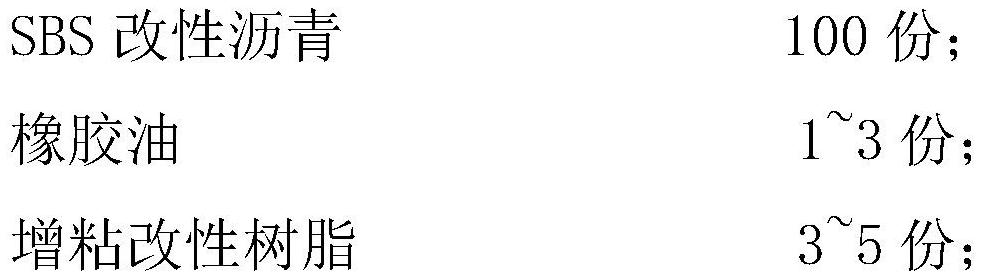

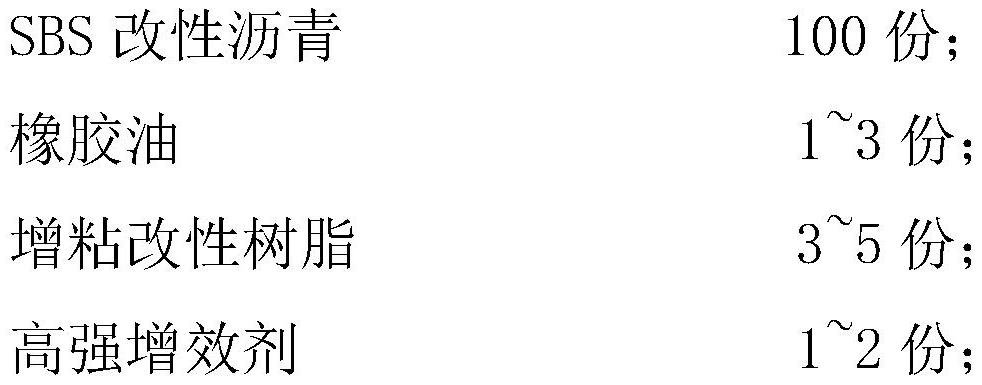

[0037] A preparation method of high-strength composite modified emulsified asphalt, the addition of the following substances is based on the quality of SBS modified asphalt:

[0038] S1. Heat and stir the SBS modified asphalt that meets the requirements of the specification to 175°C, and add 3% of the mass of SBS modified asphalt (to ensure that the viscosity index meets the requirements) rosin resin, 1.5% polystyrene butadiene Diene copolymer SBR modifier, using a high-speed shearing machine to shear for 120 minutes to obtain high-strength SBS modified asphalt, the shear speed was 700r / min during preparation, and the high-strength SBS modified asphalt was cooled to 150°C in air;

[0039] S2. Taking the high-strength SBS modified asphalt as the standard, add rubber oil accounting for 2% of the high-strength SBS modified asphalt to the high-strength composite modified asphalt, and add 0.4% of the high-strength SBS modified asphalt. Oil-soluble liquid warm mix Regenerant, the te...

Embodiment 2

[0044] A preparation method of high-strength composite modified emulsified asphalt, the addition of the following substances is based on the quality of SBS modified asphalt:

[0045] S1. Heat the SBS modified asphalt that meets the requirements of the specification to 180°C, and add 2.5% of the mass of SBS modified asphalt (to ensure that the viscosity index meets the requirements) mixture of rosin resin and coomaron resin, more than 2%. Chain polyolefin modifier, using a high-speed shearing machine to shear for 110 minutes to obtain high-strength SBS modified asphalt, the shear speed is 800r / min, and cool the high-strength SBS modified asphalt to 150°C in the air;

[0046] S2. Taking the high-strength SBS modified asphalt as the standard, add rubber oil accounting for 3% of the high-strength SBS modified asphalt to the high-strength composite modified asphalt, and add 0.5% of the high-strength SBS modified asphalt. Oil-soluble liquid warm mix Regenerant, the temperature is ke...

Embodiment 3

[0051] A preparation method of high-strength composite modified emulsified asphalt, the addition of the following substances is based on the quality of SBS modified asphalt:

[0052] S1. Heat the SBS modified asphalt that meets the requirements of the specification to 185°C, and add 3% of the mass of SBS modified asphalt (to ensure that the viscosity index meets the requirements) of terpene resin, and 2% of multi-chain polyolefin modified The high-strength SBS modified asphalt was obtained by using a high-speed shearing machine for 120 minutes, and the shear speed was 750r / min, and the high-strength SBS modified asphalt was cooled to 145°C in the air;

[0053] S2. Taking the high-strength SBS modified asphalt as the standard, add rubber oil accounting for 2.5% of the mass of high-strength SBS modified asphalt to the high-strength composite modified asphalt, and add oil-soluble liquid warm mix accounting for 0.4% of the mass of high-strength SBS modified asphalt Rejuvenator, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com