Biological fermentation tank

A bio-fermentation tank and drive shaft technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biomass post-treatment, etc., can solve the problem of unfavorable biological rapid fermentation and increase the risk of biological fermentation , unfavorable biological reproduction and fermentation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

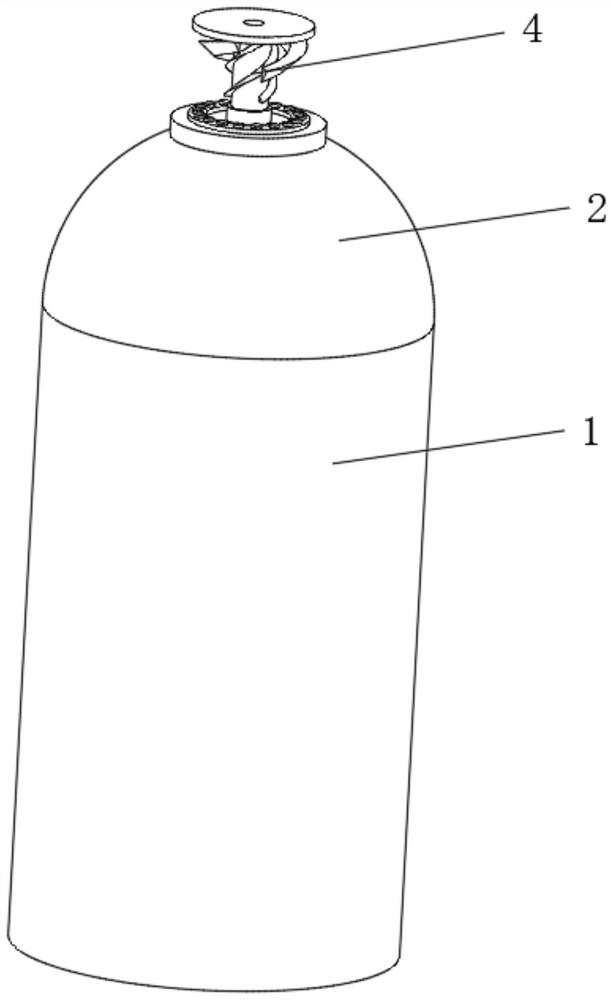

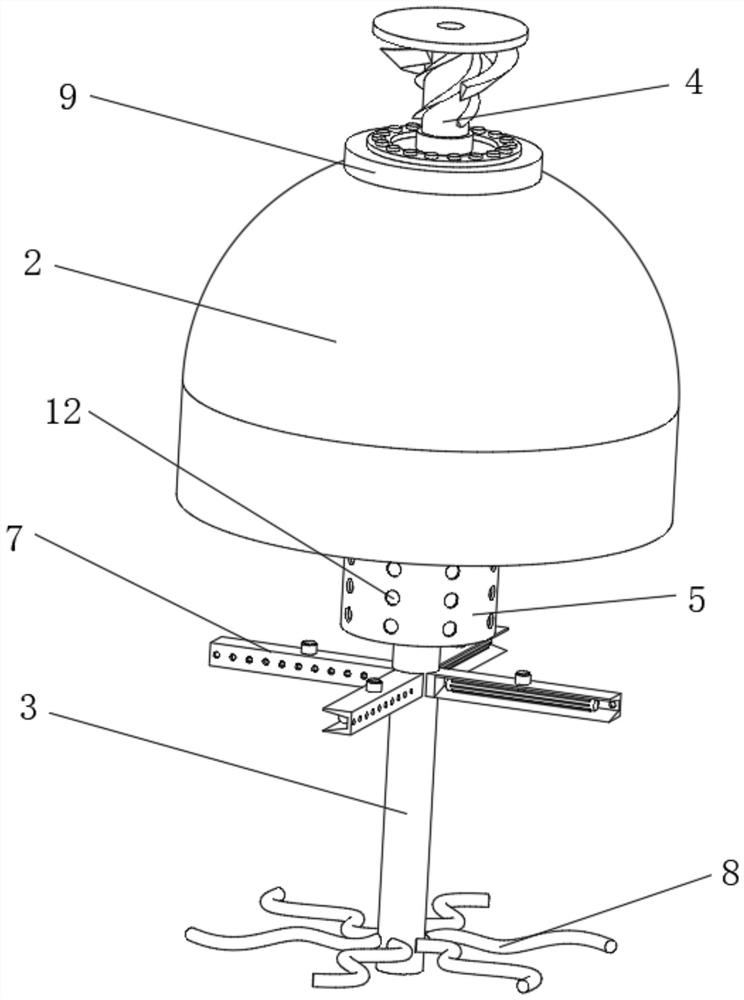

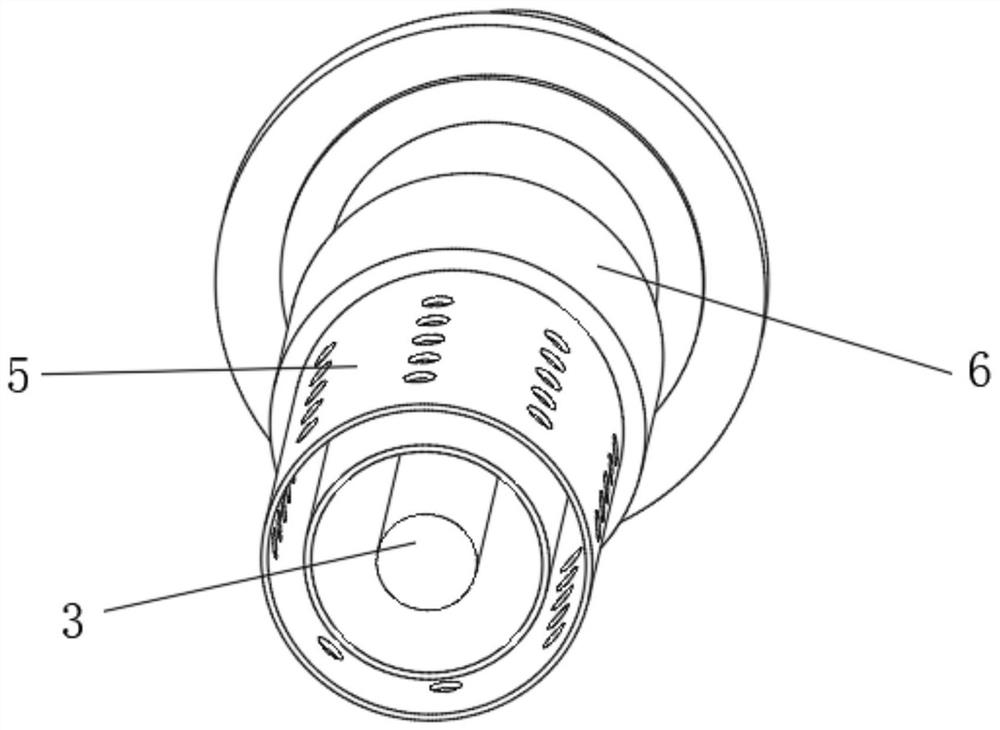

[0037] Such as Figure 1-5 As shown, the present invention provides a technical solution: a biological fermentation tank, including a fermentation inner tank 1, the top of the fermentation inner tank 1 is fixedly connected with a processing top tank 2, and the top of the processing top tank 2 is fixedly connected with an inlet sealing plate 9 , the top inside the processing top groove 2 is rotatably connected with a drive shaft 3, and one end of the drive shaft 3 extending to the top of the processing top groove 2 is fixedly connected with an exhaust drive mechanism 4, and the top of the processing top groove 2 is located outside the drive shaft 3 The quantitative discharge frame 6 is fixedly connected to the position of the quantitative discharge frame 6, and the bottom of the quantitative discharge frame 6 is fixedly connected with the defoaming outer frame 5. And the position below the defoaming outer frame 5 is evenly and fixedly connected with a shoveling mechanism 7, and...

Embodiment 2

[0042] Such as Figure 6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a biological fermenter, the exhaust drive mechanism 4 includes an auxiliary connecting shaft 401, and the bottom axis of the auxiliary connecting shaft 401 is connected to the drive shaft 3 Fixedly connected, the top of the auxiliary coupling shaft 401 is fixedly connected with a windshield backing plate 402 .

[0043] The outer surface of the auxiliary coupling shaft 401 is evenly and fixedly connected with a driving spiral piece 403 , and both sides of the bottom of the windshield backing plate 402 are fixedly connected with aerodynamic blades 404 . Realize the complete guidance of the pressure release to form a mechanical force to ensure that the fermentation liquid can be fully stirred.

[0044] The aerodynamic vane 404 is arranged outside the driving helical piece 403 , and the output direction of the aerodynamic vane 404 arranged outside the driving heli...

Embodiment 3

[0046] Such as Figure 7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a biological fermenter, the exhaust drive mechanism 4 includes an auxiliary coupling shaft 401, and the bottom axis of the auxiliary coupling shaft 401 is connected to the The driving shaft 3 is fixedly connected, and the top of the auxiliary shaft 401 is fixedly connected with a windshield backing plate 402 .

[0047] The outer surface of the auxiliary coupling shaft 401 is evenly and fixedly connected with a driving spiral piece 403 , and both sides of the bottom of the windshield backing plate 402 are fixedly connected with aerodynamic blades 404 . Realize the complete guidance of the pressure release to form a mechanical force to ensure that the fermentation liquid can be fully stirred.

[0048] The aerodynamic vane 404 is arranged outside the driving helical piece 403 , and the output direction of the aerodynamic vane 404 arranged outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com