Method for producing medium manganese steel through cyclic quenching and I-Q&P treatment and application of method

A technology of I-Q&P and manganese steel, applied in the field of advanced high-strength steel preparation, can solve the problems of low impact energy absorption capacity, deformation or fracture of structural parts, intrusion, etc., and achieve austenite stability improvement, strength and plasticity Elevation, the effect of increasing the manganese content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

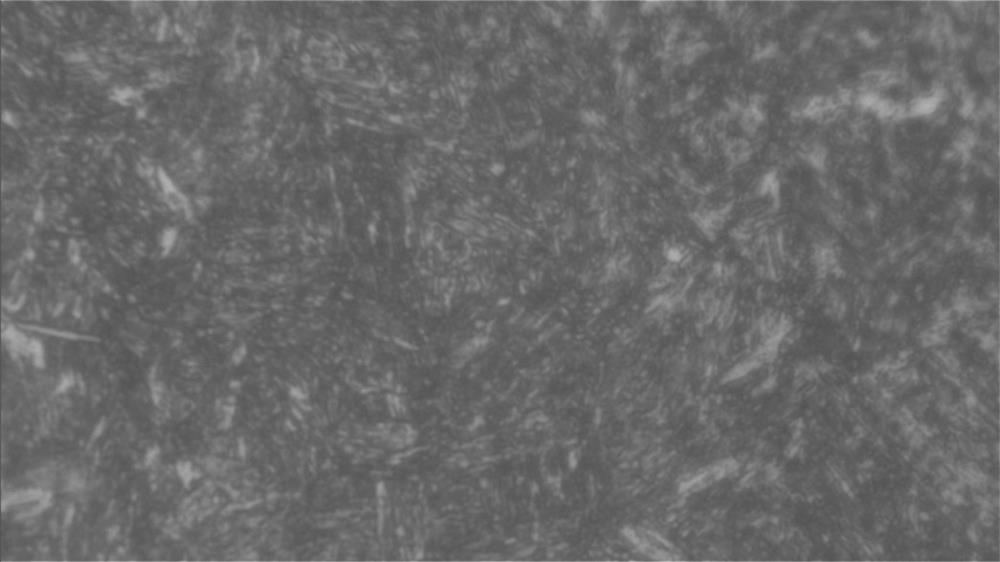

no. 1 example

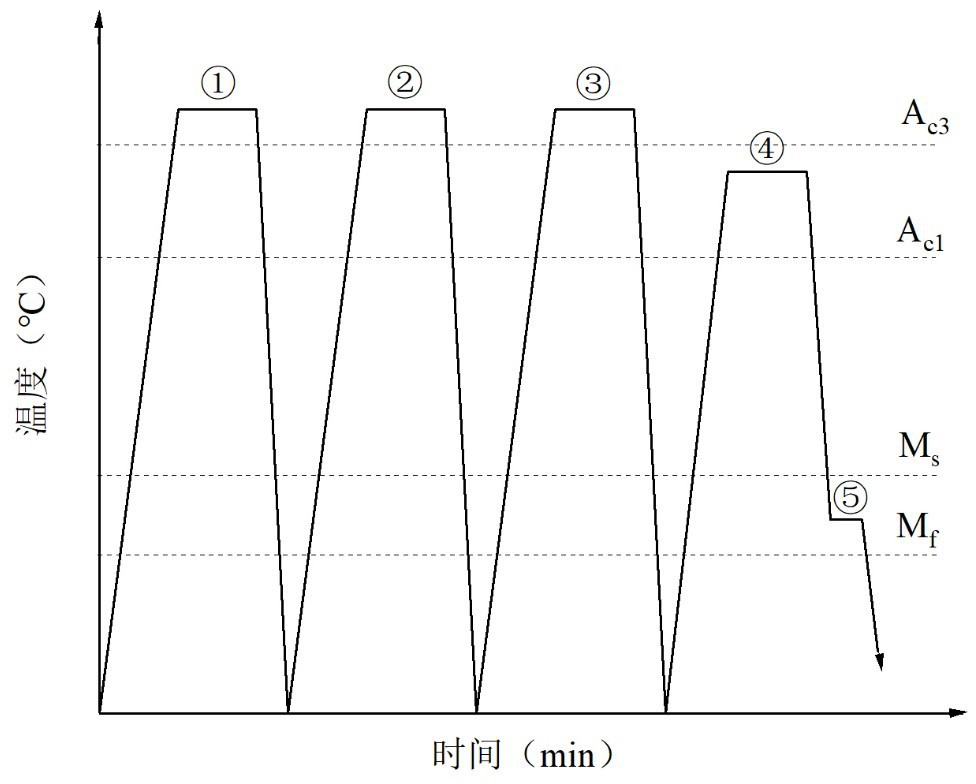

[0041] A method for circulating quenching+I-Q&P processing to produce medium manganese steel, comprising the steps:

[0042] (1) Select a medium manganese steel plate with a thickness of 2.7mm as the original steel plate, and its composition is C: 0.08%, Mn: 4.96%, Cu: 0.53%, Mo: 0.18%, Cr: 0.35%, Nb: 0.10 %, P: 0.005%, S: 0.006%, and the balance is Fe and unavoidable impurities. The austenite transformation end temperature (AC 3 -1), which is 740°C.

[0043] (2) Heat the original steel plate to 780°C for 5 minutes, and then water quench to room temperature; heat again to 780°C for 5 minutes, then water quench to room temperature; heat for the third time to 780°C, hold for 5 minutes, and water quench to At room temperature, a circulating quenched steel plate was obtained.

[0044] (3) The austenite transformation initiation temperature (AC 1 -2), austenite transformation end temperature (AC 3 -2), martensite transformation start temperature (Ms-2), martensite transformati...

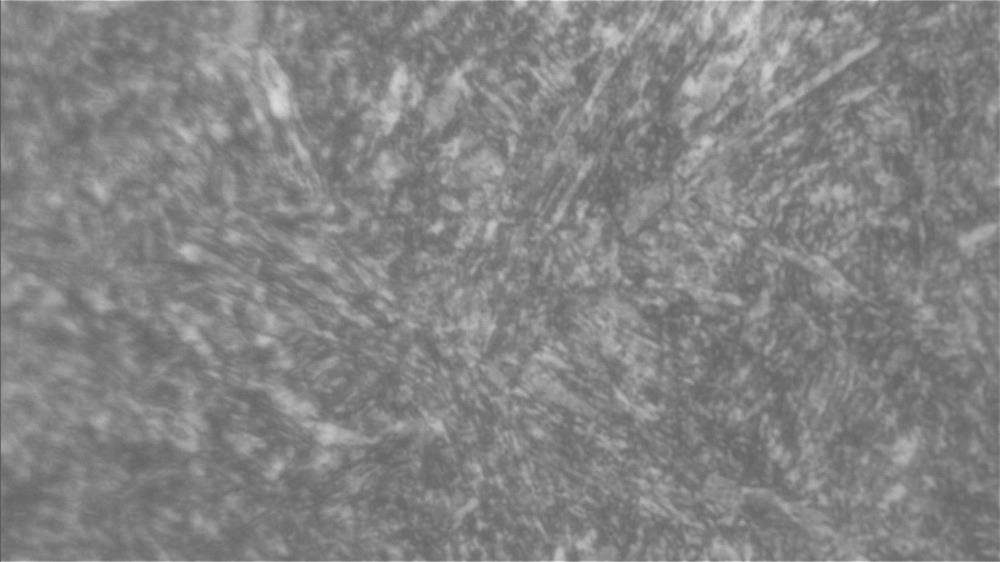

no. 2 example

[0055] A method for circulating quenching+I-Q&P processing to produce medium manganese steel, comprising the steps:

[0056] (1) Select a medium manganese steel plate with a thickness of 2.7mm as the original steel plate, and its composition is C: 0.08%, Mn: 4.96%, Cu: 0.53%, Mo: 0.18%, Cr: 0.35%, Nb: 0.10 %, P: 0.005%, S: 0.006%, and the balance is Fe and unavoidable impurities. The austenite transformation end temperature (AC 3 -1), which is 740°C.

[0057] (2) Heat the original steel plate to 780°C for 5 minutes, and then water quench to room temperature; heat again to 780°C for 5 minutes, then water quench to room temperature; heat for the third time to 780°C, hold for 5 minutes, and water quench to At room temperature, a circulating quenched steel plate was obtained.

[0058] (3) The austenite transformation initiation temperature (AC 1 -2), austenite transformation end temperature (AC 3 -2), martensite transformation start temperature (Ms-2), martensite transformati...

no. 3 example

[0069] A method for circulating quenching+I-Q&P processing to produce medium manganese steel, comprising the steps:

[0070] (1) Select a medium manganese steel plate with a thickness of 3.0mm as the original steel plate, and its composition is C: 0.10%, Mn: 5.00%, Cu: 0.50%, Mo: 0.20%, Cr: 0.39%, Nb: 0.08 %, P: 0.003%, S: 0.004%, and the balance is Fe and unavoidable impurities. The austenite transformation end temperature (AC 3 -1), which is 738°C.

[0071] (2) Heat the original steel plate to 760°C for 5 minutes, and then water quench to room temperature; heat again to 780°C for 5 minutes, then water quench to room temperature; heat for the third time to 780°C, hold for 5 minutes, and water quench to At room temperature, a circulating quenched steel plate was obtained.

[0072] (3) The austenite transformation initiation temperature (AC 1 -2), austenite transformation end temperature (AC 3 -2), martensite transformation start temperature (Ms-2), martensite transformati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com