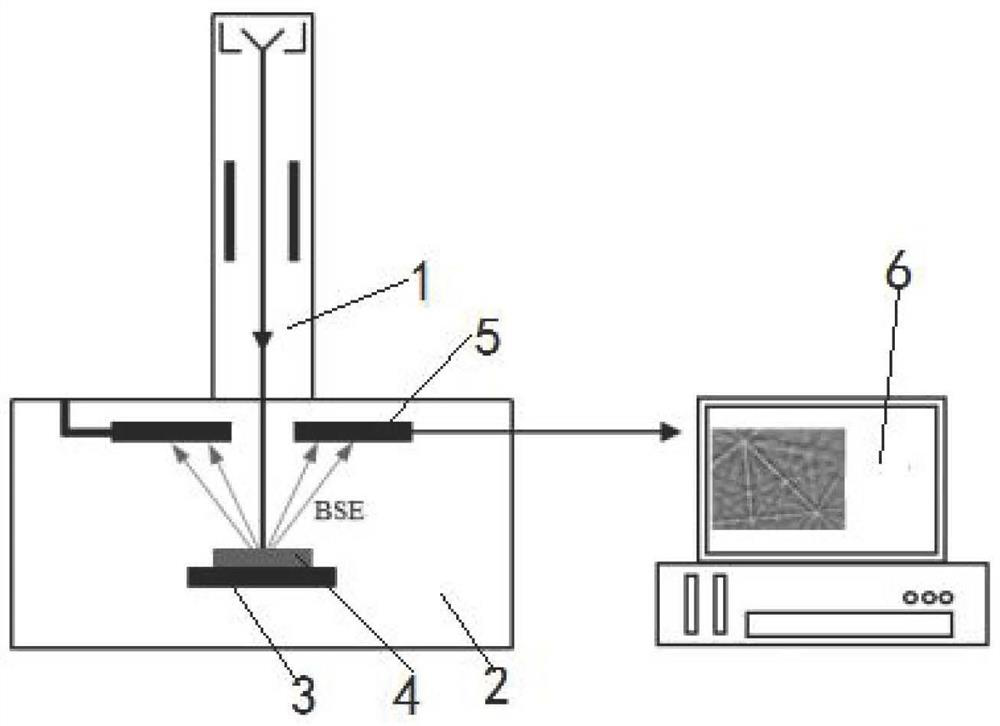

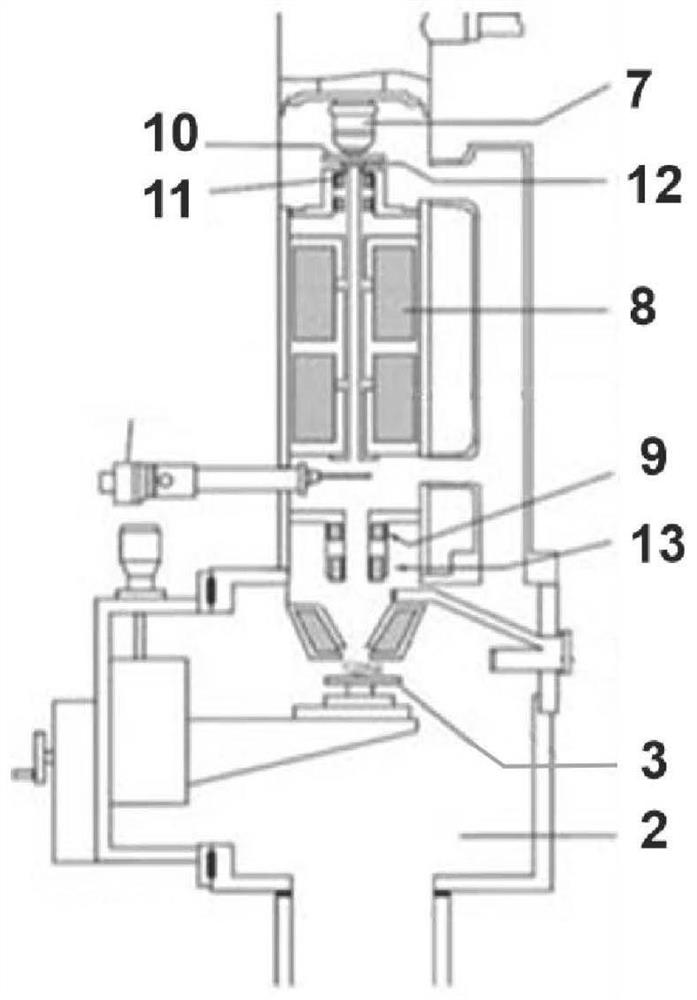

Flat insertion type electronic probe and detection method

A flat plug-in, electronic technology, applied in the direction of measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve problems such as poor spatial resolution, difficult electron beam focusing, large working distance, etc., to achieve spatial resolution High rate, overcome the effect of small representation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specification and claims do not use the difference in name as a way to distinguish components, but use the difference in function of components as a criterion for distinguishing. As mentioned throughout the specification and claims, "comprising" is an open term, so it should be interpreted as "including but not limited to". "Approximately" means that within an acceptable error range, those skilled in the art can solve the technical problem within a certain error range and basically achieve the technical effect.

[0029] The orientation terms such as up, down, left, and right in this specification and claims are combined with the drawings for further explanation, making this application easier to understand, and not limiting this application. In different scenarios, up and down, left and right, and inside and outside are all Relatively speaking.

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com