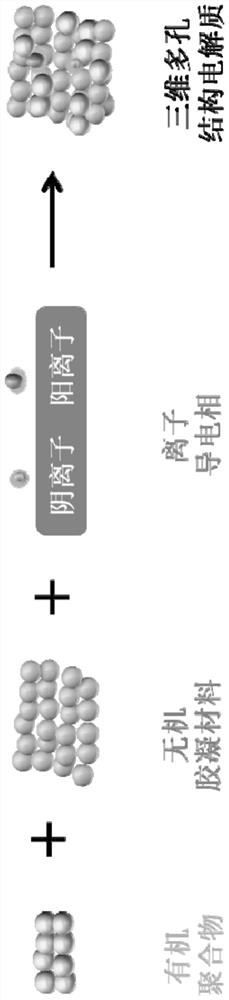

Organic/inorganic network interpenetrating three-dimensional porous structure electrolyte and preparation method thereof

A network interpenetrating, three-dimensional porous technology, applied in the field of electrochemical energy storage, can solve problems such as safety hazards, and achieve the effect of improving electrical performance and improving interface compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

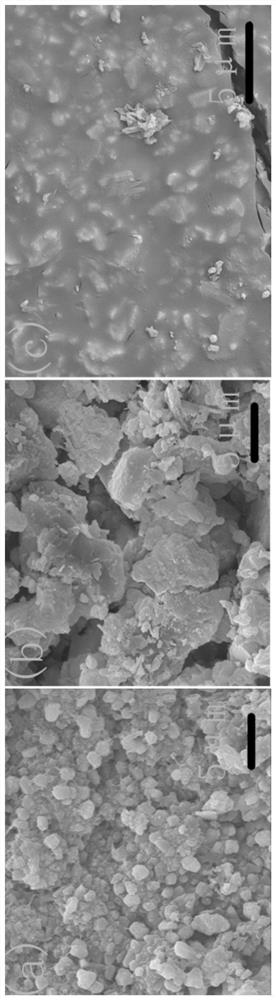

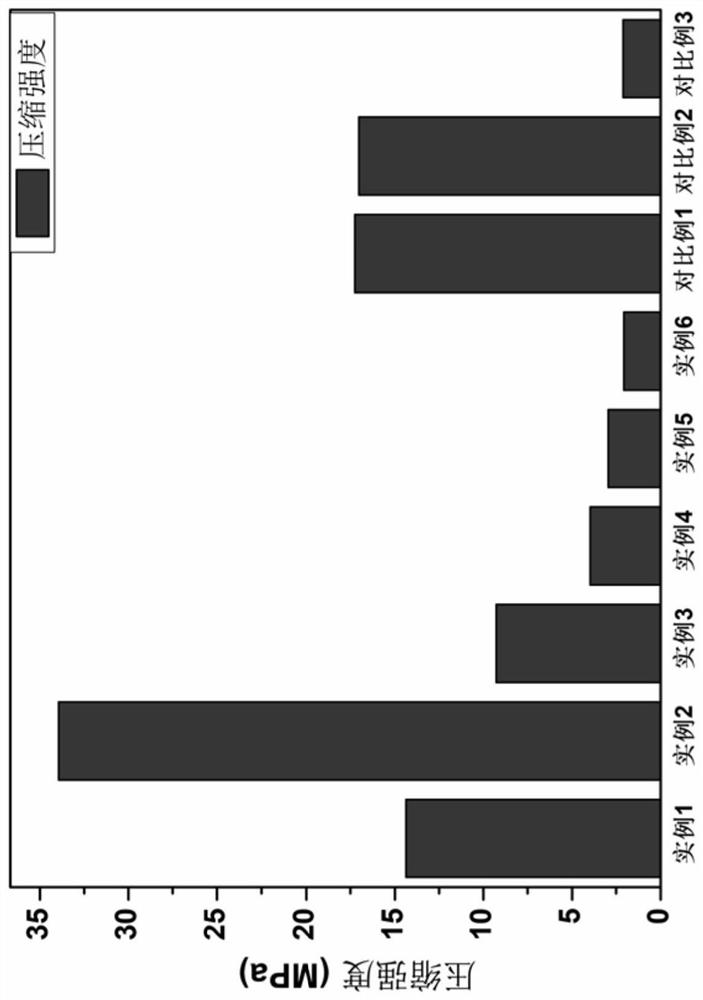

Embodiment 1

[0041] (1) Dissolve 10g of PAA in 80g of water, and fully stir at 500rpm at 25°C for 30min to obtain a uniform organic polymer aqueous solution;

[0042](2) adding 8g KOH to the aqueous solution of step (1), fully stirring at room temperature for 15 min at 500rpm to obtain a uniform organic polymer electrolyte;

[0043] (3) adding 200g cement powder to the electrolyte of step (2), fully stirring at room temperature for 120s at 200r / min to obtain a uniform slurry;

[0044] (4) pour the uniform slurry in step (3) into 3*3*3cm 3 It was hardened and formed in a silica gel mold, and then put into a cement curing room (temperature 22° C., relative humidity 90%) for curing for 28 days. After demoulding, a cube-shaped electrolyte was obtained for mechanical property testing.

[0045] (5) Insert the cut stainless steel sheet into 1*1*1cm 3 After the two ends of the silicone mold, the uniform slurry in step (3) is poured into the mold to harden and form, and then put into a cement cur...

Embodiment 2

[0047] (1) Dissolve 20g PAA in 80g water, fully stir for 30min at 500rpm at 25°C to obtain a uniform organic polymer aqueous solution;

[0048] (2) 8g KOH was added to the aqueous solution of step (1), fully stirred at 500rpm for 15min at room temperature to obtain a uniform organic polymer electrolyte;

[0049] (3) adding 200g cement powder to the electrolyte of step (2), fully stirring at room temperature for 120s at 200r / min to obtain a uniform slurry;

[0050] (4) pour the uniform slurry in step (3) into 3*3*3cm 3 It was hardened and formed in a silica gel mold, and then put into a cement curing room (temperature 22° C., relative humidity 90%) for curing for 28 days. After demoulding, a cube-shaped electrolyte was obtained for mechanical property testing.

[0051] (5) Insert the cut stainless steel sheet into 1*1*1cm 3 After the two ends of the silicone mold, the uniform slurry in step (3) is poured into the mold to harden and form, and then put into a cement curing room...

Embodiment 3

[0053] (1) 10g PEO was dissolved in 80g water, fully stirred at 500rpm at 25°C for 30min to obtain a uniform organic polymer aqueous solution;

[0054] (2) 20g LiCl was added to the aqueous solution of step (1), and the room temperature was fully stirred at 500rpm for 15min to obtain a uniform organic polymer electrolyte;

[0055] (3) adding 200g cement powder to the electrolyte of step (2), fully stirring at room temperature for 120s at 200r / min to obtain a uniform slurry;

[0056] (4) pour the uniform slurry in step (3) into 3*3*3cm 3 It was hardened and formed in a silica gel mold, and then put into a cement curing room (temperature 22° C., relative humidity 90%) for curing for 28 days. After demoulding, a cube-shaped electrolyte was obtained for mechanical property testing.

[0057] (5) Insert the cut stainless steel sheet into 1*1*1cm 3 After the two ends of the silicone mold, the uniform slurry in step (3) is poured into the mold to harden and form, and then put into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com