Preparation process of high-strength anticorrosive coating at corner

An anti-corrosion coating and preparation process technology, applied in the coating, the device for coating liquid on the surface, the surface pretreatment, etc., can solve the problems of peeling off, low strength of the anti-corrosion layer, air bubbles, etc., to improve the strength, The effect of reducing the probability of peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

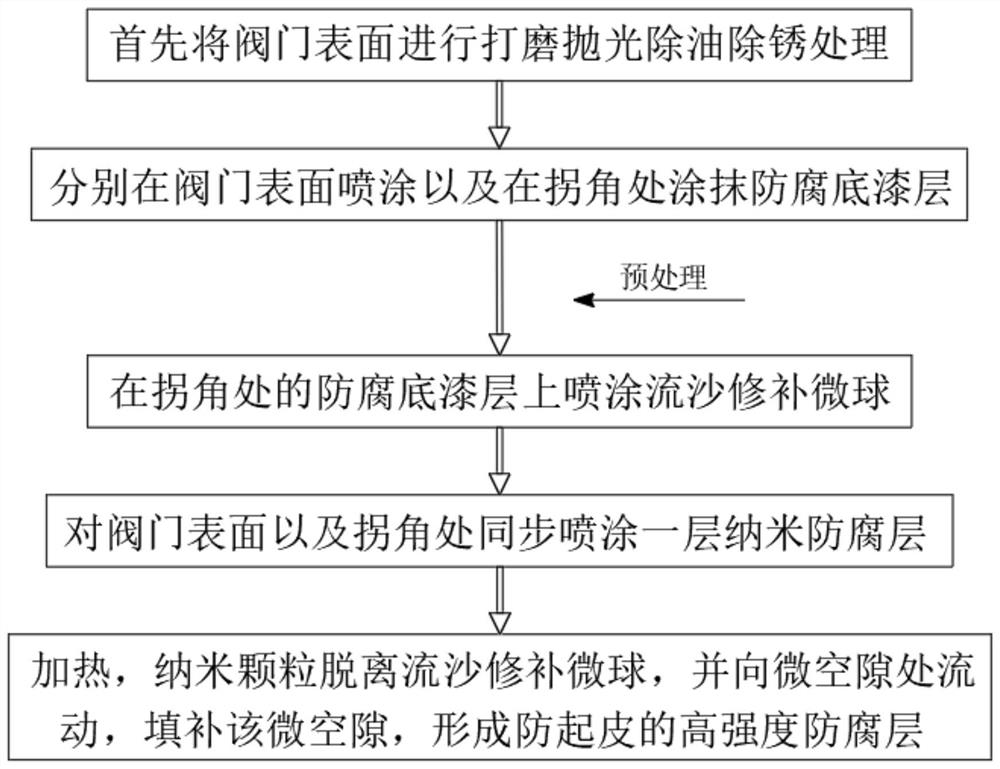

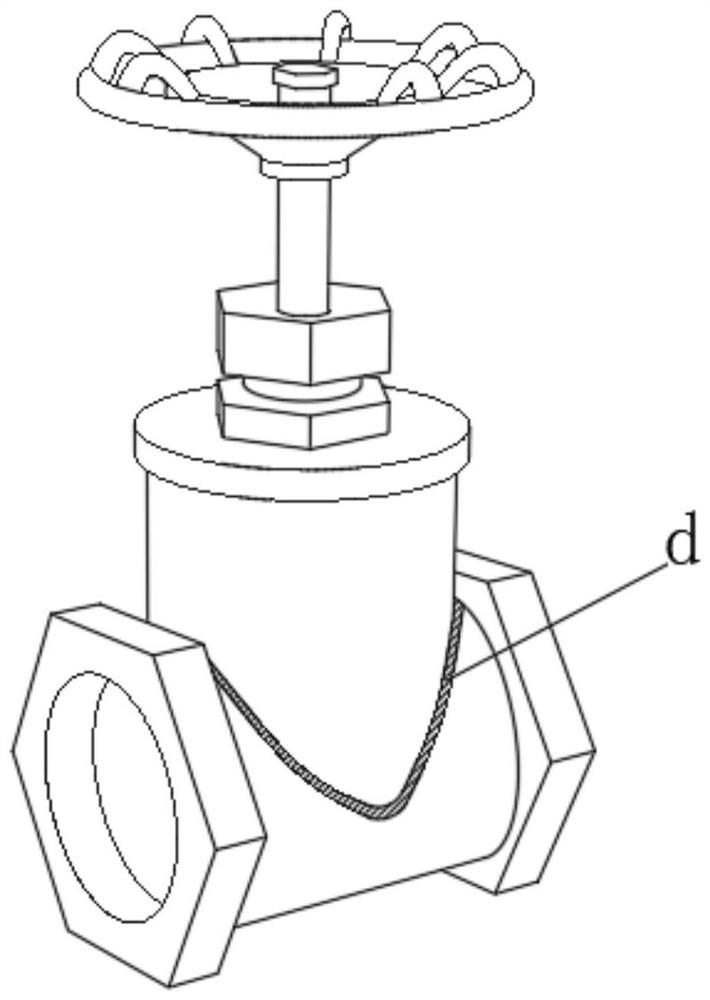

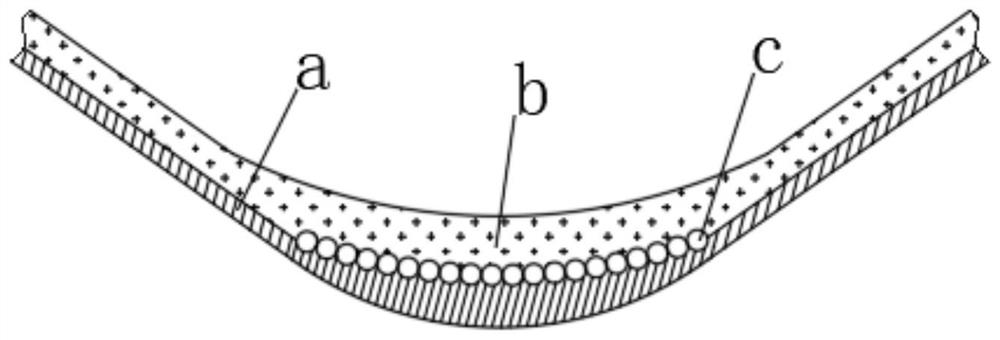

[0044] see Figure 1-2 , in the figure, a represents the anti-corrosion primer layer, b represents the nano-anti-corrosion layer, and c represents quicksand repair microspheres, a preparation process of a high-strength anti-corrosion coating at a corner, including the following steps:

[0045] S1. First, the surface of the valve is polished and polished to remove oil and rust;

[0046] S2. Spray an anti-corrosion primer layer on the surface of the valve, and apply an anti-corrosion primer layer on the corner of the valve surface;

[0047] S3. First, the quicksand repair microspheres are pretreated before spraying, and then a layer of pretreated quicksand repair microspheres is sprayed on the anti-corrosion primer layer at the corner;

[0048] The specific operation of the pretreatment of quicksand repair microspheres in S3 is as follows:

[0049] S31. Firstly, in a high-humidity environment, the rapid cooling treatment is performed on the quicksand repair microspheres, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com