Method for collecting and applying process parameters of industrial robot

An industrial robot and process parameter technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as inability to collect process data, poor process intelligence, and optimize process knowledge bases, to solve problems such as low production programming efficiency, The effect of lowering the technical threshold and improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

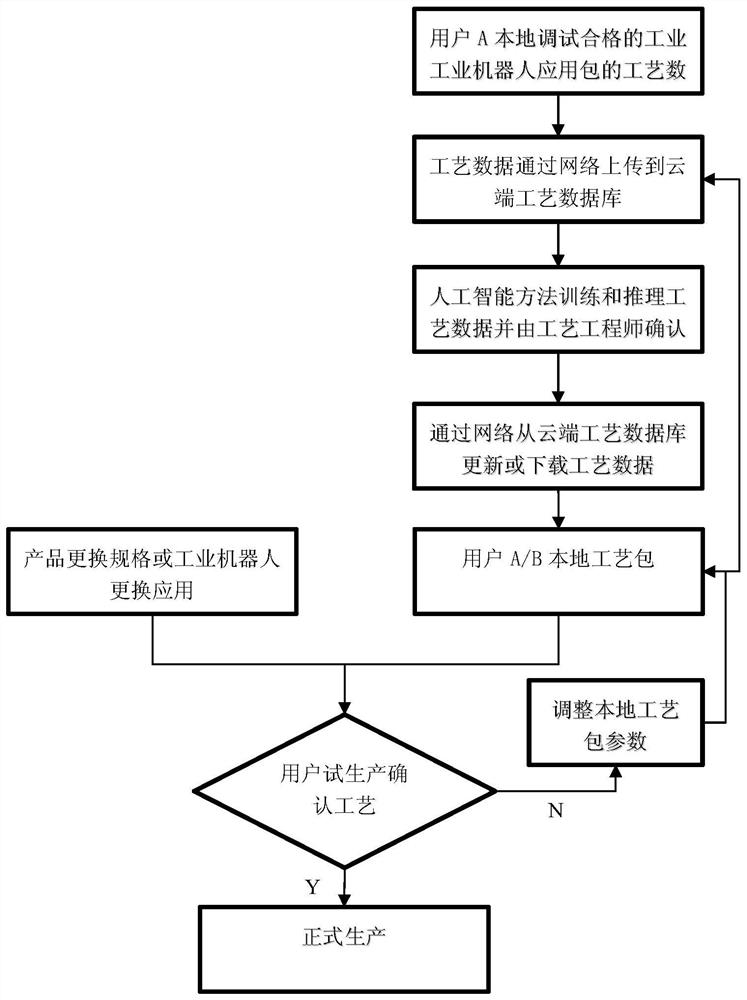

[0019] Refer to attached figure 1 , the steps implemented in this embodiment are:

[0020] step 1:

[0021] Define a process package template on the local controller of the industrial robot. The process package contains the speed information of the end effector of the industrial robot, the attribute information of the workpiece and the complete process data that has been debugged and qualified by experienced craftsmen. The process package can be a welding process package, gluing process package, cutting process package, grinding process package, assembly process package, deburring process package, etc., the type of process package can be added later according to different job types;

[0022] Step 2:

[0023] The above process software package data can be uploaded to the cloud process database through the network. The process database stores process data from different industrial robot applications. The same industrial robot application has process data from different industr...

Embodiment 2

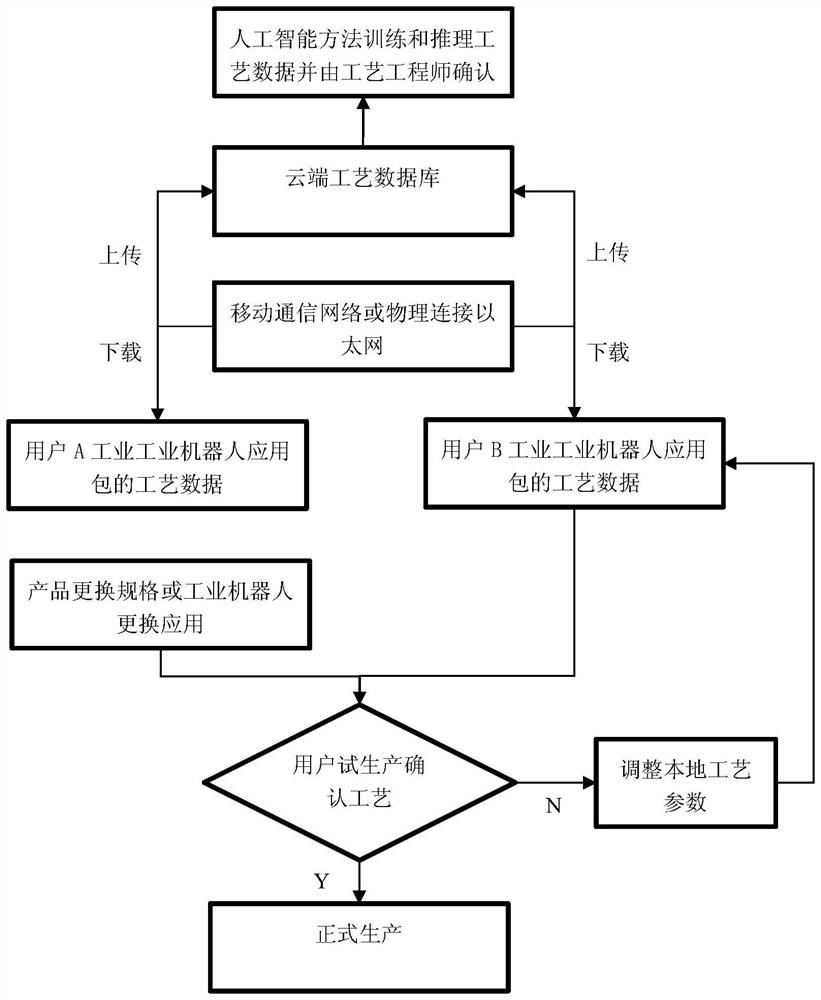

[0031] Refer to attached figure 2 , the steps implemented in this embodiment are:

[0032] step 1:

[0033] Define a process package template on the local controller of the industrial robot. The industrial robot has built-in some process package types and data before leaving the factory. Users can create process packages or add process data in actual use;

[0034] Step 2:

[0035] The process package defined in step 1 usually includes the speed information of the end effector of the industrial robot, the attribute information of the workpiece, and the complete process data qualified for debugging. The process package types can be welding process package, gluing process package, cutting process package, and grinding process package. , assembly process package, deburring process package, etc., the type of process package can be added later according to different job types;

[0036] Step 3:

[0037] The process package data described in step 1 is uploaded to the cloud proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com