Window glass structure, manufacturing method thereof and vehicle comprising window glass structure

A window glass and vehicle technology, applied in the field of vehicles, can solve the problems of heavy weight, broken glass, loss of personnel and property, etc., and achieve the effect of reducing weight and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The window glass of the present application can be used for, but not limited to, side windows of vehicles, front windshields, rear windshields, sunroofs and the like.

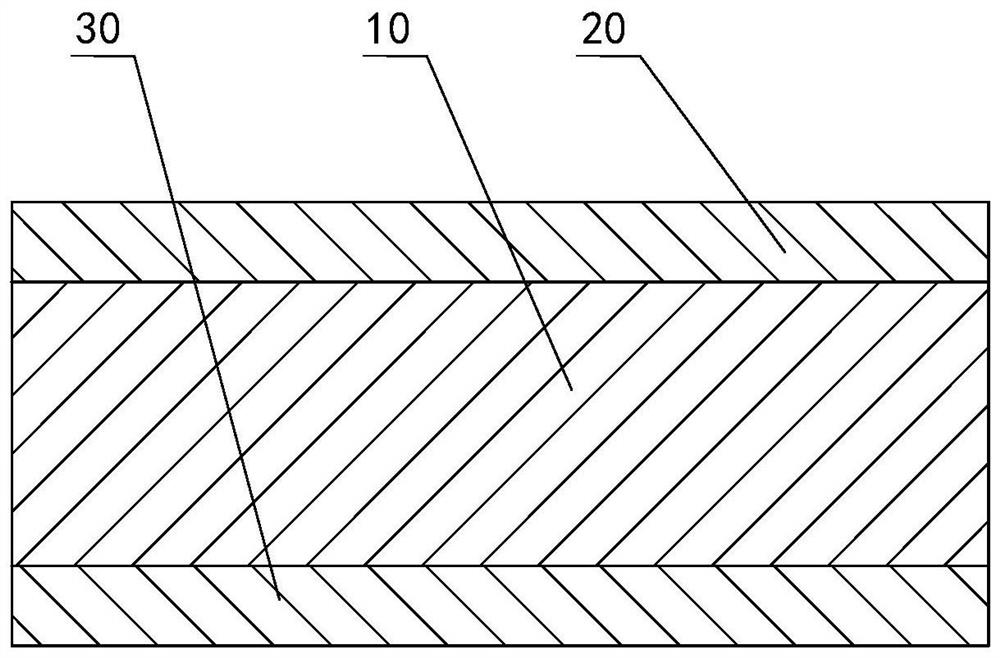

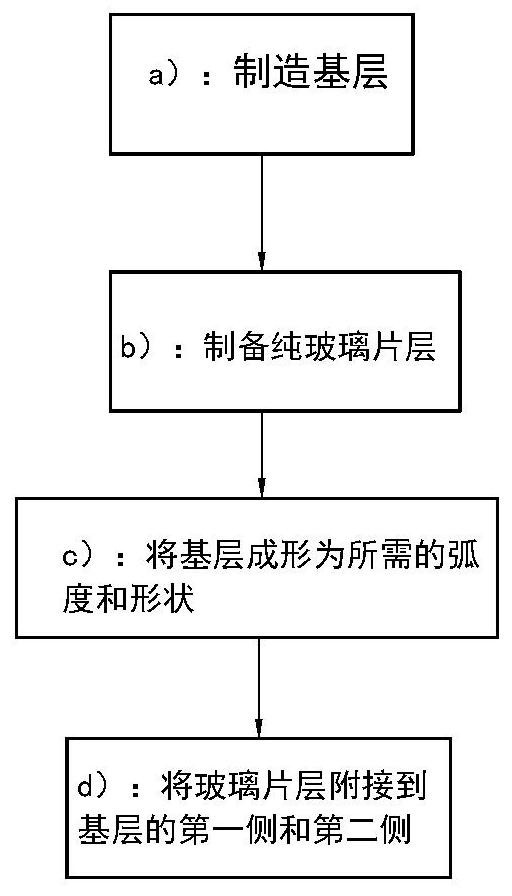

[0026] figure 1 is a schematic cross-sectional view of the window glass structure of the present application. The glazing structure of the present application basically includes a base layer 10 defining opposite first and second sides and first and second glass sheet layers 20 and 30 located on the first and second sides of the base layer 10, respectively.

[0027] The base layer 10 is made of transparent polymer material. In one embodiment, base layer 10 may be formed from a plastic material. In another embodiment, the base layer 10 can be formed of organic materials, and the organic materials that can be used to form the base layer 10 include, but are not limited to, polymethyl methacrylate (PMMA), polystyrene (PS), polycarbonate ( PC), styrene acrylonitrile (AS and SAN), styrene-methyl methacrylate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com