Pretreatment rinsing system for textile printing and dyeing industry

A technology in the textile printing and dyeing industry, applied in the field of pre-treatment and rinsing systems in the textile printing and dyeing industry, can solve the problems of multiple washing units, high tension, and wrinkling, and achieve the effects of improving fabric whiteness, high washing efficiency, and improving shade and feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

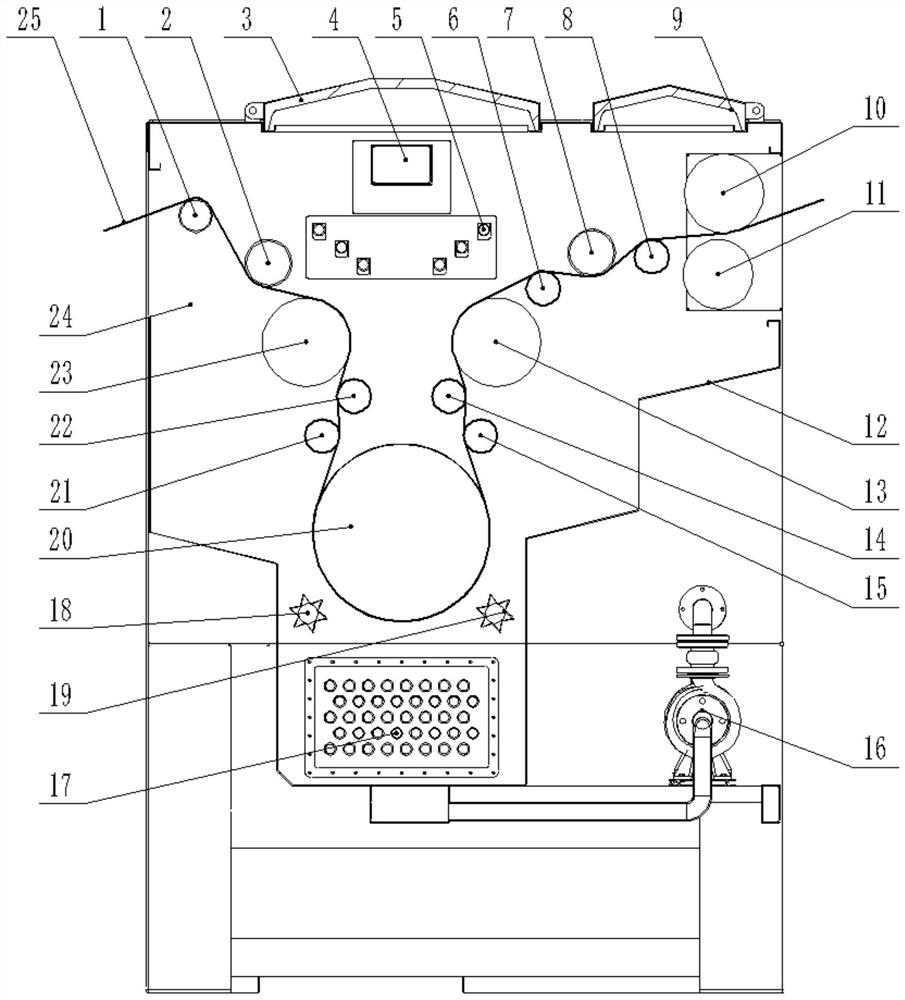

[0048] Embodiment 1 of the present invention The pretreatment and rinsing system of the textile printing and dyeing industry includes a washing box and a washing filter degreasing device, and the water washing box is connected with the washing filter degreasing device;

[0049] Such as figure 1As shown, it is a schematic structural view of the washing box in the pretreatment and rinsing system of the textile printing and dyeing industry in Example 1 of the present invention; wherein, 1 is the washing tension roller, 2 is the first cloth guide roller for washing, 3 is the first inspection cover for washing, and 4 is Smelting lighting, 5 is the water washing spray pipe, 6 is the first water separation roller for water washing, 7 is the second cloth guide roller for water washing, 8 is the second water separation roller for water washing, 9 is the second inspection cover for water washing, and 10 is for water washing The upper roll, 11 is the washing lower roll, 12 is the washing...

Embodiment 2

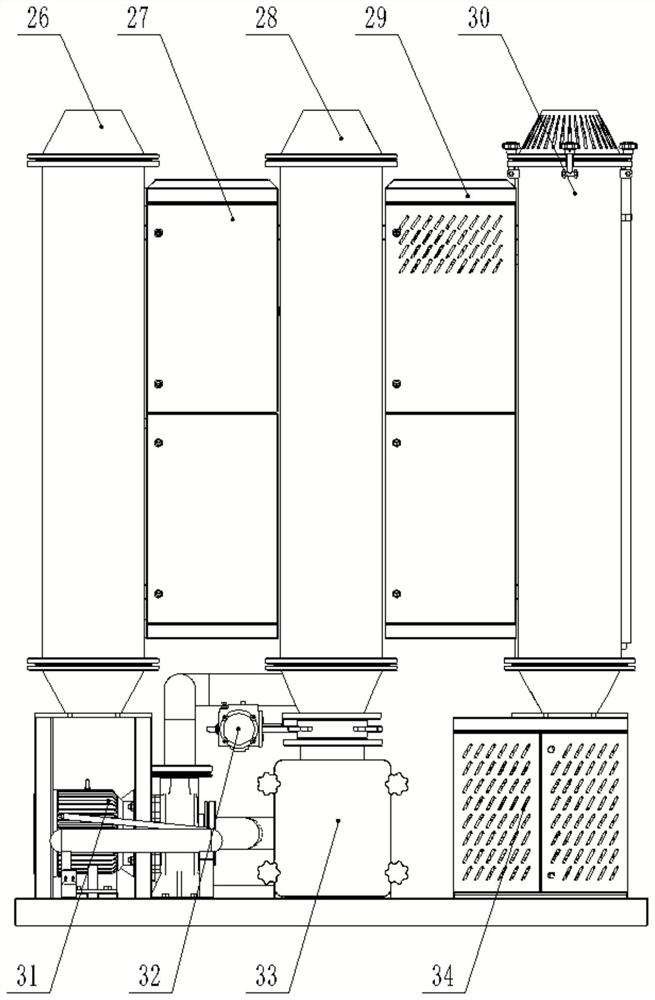

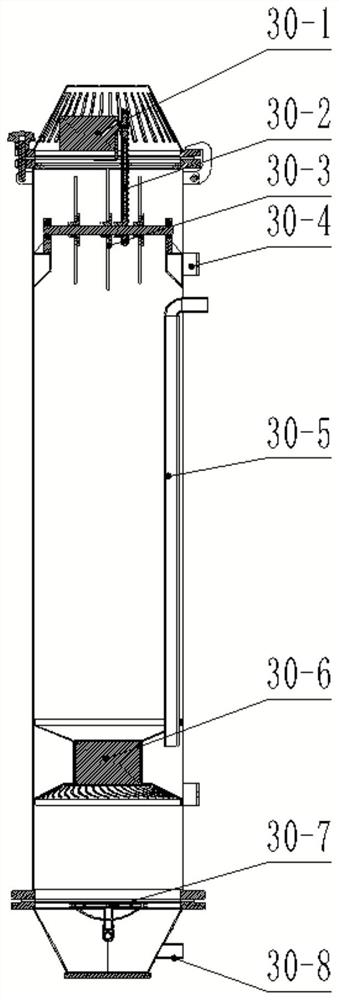

[0064] Others are exactly the same as in Example 1, the difference is that Example 2 of the present invention is provided with three washing tanks and three washing and filtering degreasing devices, which are respectively: the first washing tank, the second washing tank and the third washing tank; the first washing tank Water washing filtration and degreasing device, the second water washing filtration and degreasing device and the third water washing filtration and degreasing device; the water in the first water washing tank enters the first water washing filtration and degreasing device for filtering and degreasing, waste solid and oil recovery , the treated water is returned to the washing tank for recycling; the water in the second washing tank enters the second washing filtration and degreasing device for filtering and degreasing, waste solids and oil are recovered, and the treated water is returned to the second washing tank for recycling The water in the third washing ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com