Fruit and vegetable natural yeast acid dough and preparation method thereof

A natural yeast, fruit and vegetable fermentation technology, applied in dough preparation, pre-baked dough processing, baking, etc., can solve the problems of low fermentation power, low number of viable bacteria, unable to meet the high quality requirements of products, etc., and achieve strong gas retention. , strong fermentation activity, inhibiting the effect of easily producing toxic and harmful microorganisms and toxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

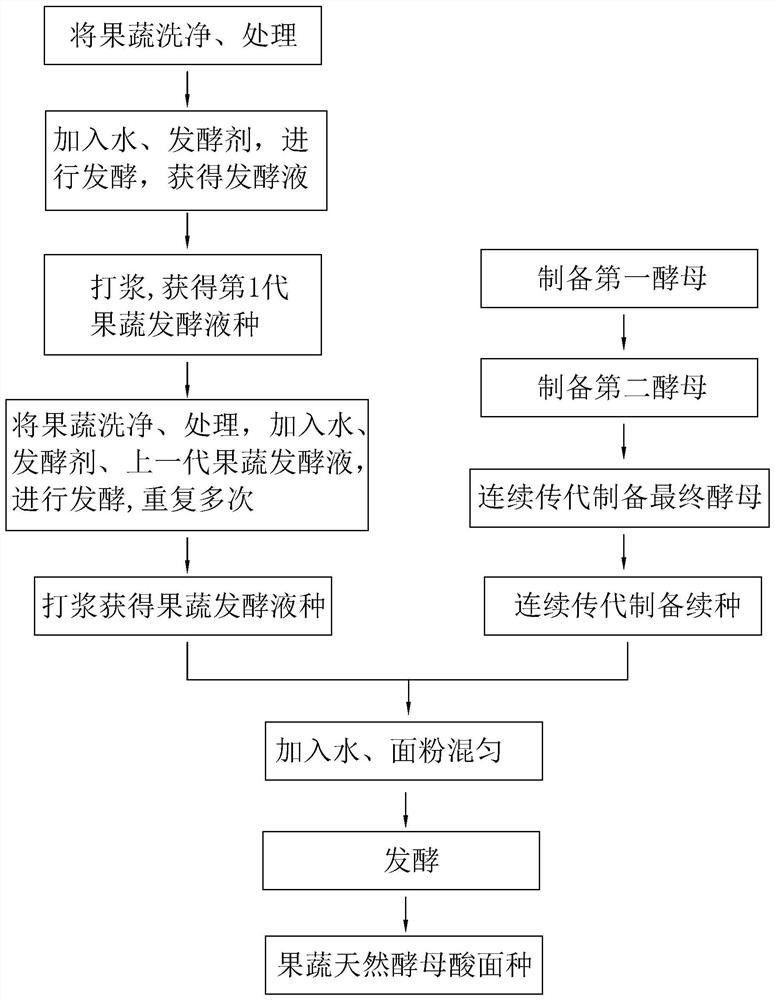

Method used

Image

Examples

preparation example 1

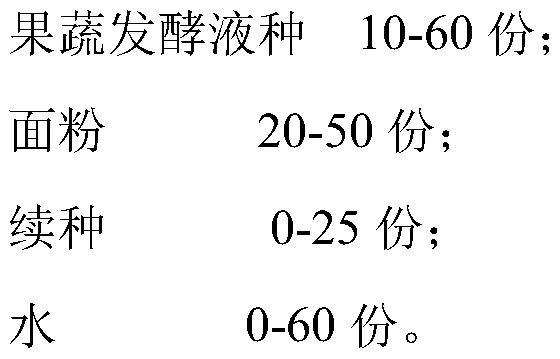

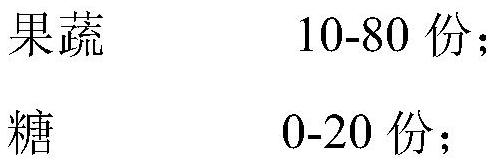

[0055] Prepare raisin fermented liquid kind, by weight, be made from the raw material in Table 1, preparation method is as follows:

[0056] S1, wash and select the raisins, and place them in a clean container;

[0057] S2, adding water and starter, mixing evenly and placing in an environment of 27°C, fermenting for 3 days to obtain raisin fermentation liquid;

[0058] S3, placing the raisin fermentation liquid in a beater for beating to obtain the first generation of raisin fermentation liquid;

[0059] S4, repeating S1, adding water, starter, and the first-generation raisin fermentation liquid, mixing, and fermenting at 27°C for 3 days to obtain the raisin fermentation liquid;

[0060] S5, beating the raisin fermentation liquid obtained in S4 to obtain a raisin fermentation liquid;

[0061] S6, refrigerated storage for later use.

[0062]The starter is composed of 5 strains of Lactobacillus plantarum, Lactococcus lactis subsp. lactis, Pediococcus lactis, Lactobacillus par...

preparation example 2

[0064] Prepare orange fermented liquid kind, by weight, be made from the raw material in table 1, preparation method is as follows:

[0065] S1, the oranges are washed, selected, cut into pieces, and placed in a clean container;

[0066] S2, adding water, white sugar, and starter, mixing evenly and placing in an environment of 27°C, and fermenting for 3 days to obtain orange fermented liquid;

[0067] S3, placing the orange fermented liquid in a beater for beating to obtain the first generation orange fermented liquid;

[0068] S4, repeating S1, adding water, white granulated sugar, starter, and the first-generation orange fermentation broth, mixing, placing in an environment of 27°C, and fermenting for 3 days to obtain orange fermentation broth;

[0069] S5, beating the orange fermented liquid to obtain orange fermented liquid seeds.

[0070] S6, refrigerated storage for later use.

[0071] The starter is composed of 5 strains of Lactobacillus plantarum, Lactococcus lactis...

preparation example 3

[0073] The difference between the preparation of orange fermented liquid and Preparation Example 2 is that it is made from the raw materials in Table 1 in parts by weight.

[0074] The starter is composed of 7 strains of Lactobacillus plantarum, Lactococcus lactis subsp. lactis, Pediococcus lactis, Lactobacillus paracasei, Leuconostoc enterococci subsp. enterica, Saccharomyces cerevisiae and Kluyveromyces marx. equal parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com