Centralized heating flue gas desulfurization and denitrification treatment system and method thereof

A technology of desulfurization and denitrification and treatment system, which is applied in the flue gas desulfurization and denitrification treatment system with centralized heating, in the field of flue gas desulfurization and denitrification, and can solve the problems of consuming more fuel and polluting the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

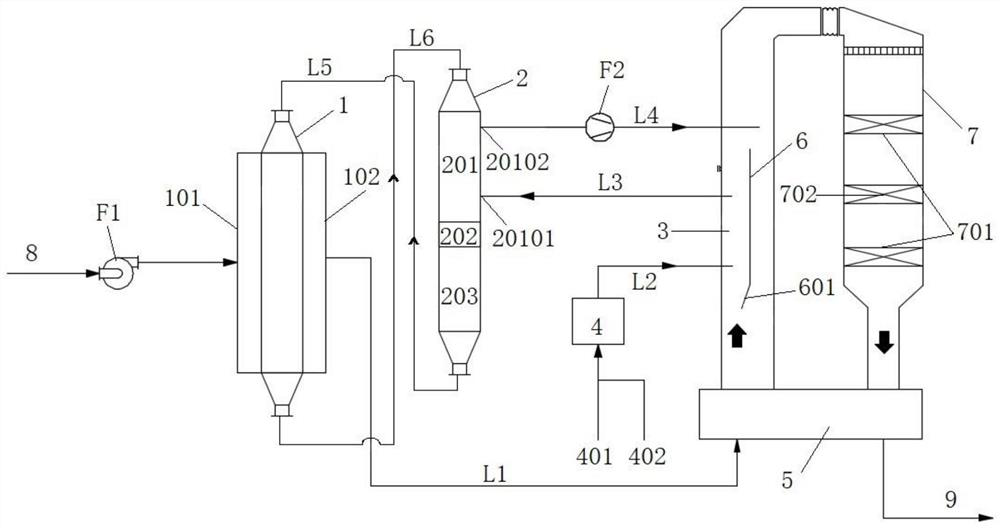

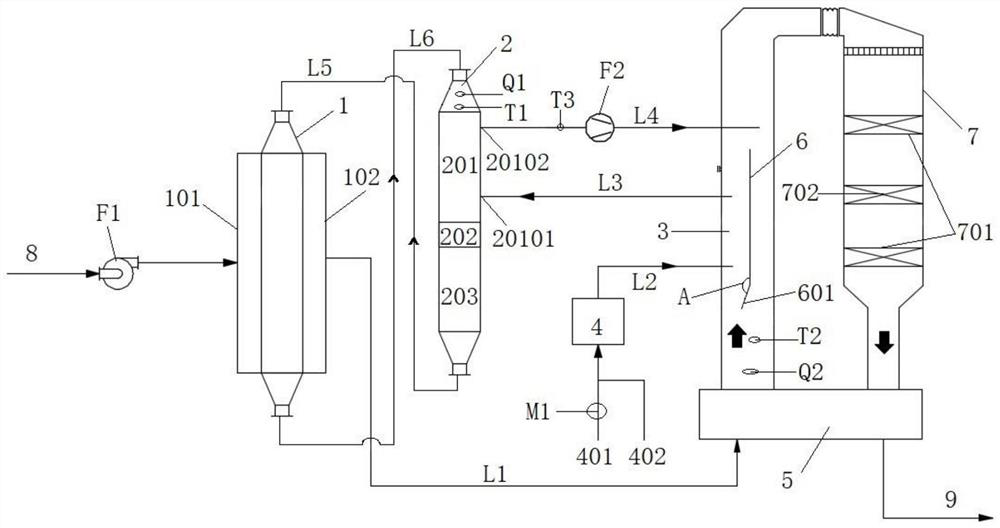

[0111] Such as figure 1 As shown, a centralized heating flue gas desulfurization and denitrification treatment system includes an activated carbon adsorption tower 1, an activated carbon desorption tower 2, a hot blast stove 4 and an SCR reactor 7. According to the direction of flue gas, one side of the activated carbon adsorption tower 1 is provided with a raw flue gas inlet 101 , and the other side is provided with a desulfurized flue gas outlet 102 . The desulfurized flue gas outlet 102 is connected to the SCR reactor 7 through the first pipeline L1. The clean flue gas discharged from the SCR reactor 7 is discharged through the gas outlet of the SCR reactor 7 . A deflector 6 is arranged in the first pipeline L1. The cavity formed between the deflector 6 and the side wall of the first pipe L1 forms the air mixing chamber 3 , and the air outlet of the hot stove 4 communicates with the air mixing chamber 3 through the second pipe L2 .

[0112] Wherein, the activated carbon ...

Embodiment 2

[0114] Embodiment 1 is repeated, except that the lower end of the deflector 6 is provided with a movable plate 601 . The size of the air inlet of the air mixing chamber 3 is regulated by controlling the opening and closing degree of the movable plate 601 .

Embodiment 3

[0116] Example 2 was repeated, except that the system also included a GGH heat exchanger 5 . The gas outlet from the SCR reactor 7 is connected with an exhaust pipe 9 . The GGH heat exchanger 5 is connected to the first pipeline L1 and the exhaust pipeline 9 respectively. The flue gas desulfurized by the activated carbon adsorption tower 1 is sent to the air inlet of the SCR reactor 7 after heat exchange by the GGH heat exchanger 5 . The clean flue gas discharged from the SCR reactor 7 is discharged through the exhaust pipe 9 after being heat-exchanged by the GGH heat exchanger 5 . The communication position between the second pipeline L2 and the air mixing chamber 3 is located downstream of the connection position between the GGH heat exchanger 5 and the first pipeline L1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com