Wave-shaped supporting plate, tower equipment and application

A wave type and equipment technology, which is applied in the direction of catalytic conversion of impurities, gas purification, chemical/physical/physicochemical processes, chemical instruments and methods, etc., can solve the problems such as the opening rate is difficult to break through 100%, and the contact surface is small, reaching Improve stability and filler utilization, high porosity, and improve hydrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

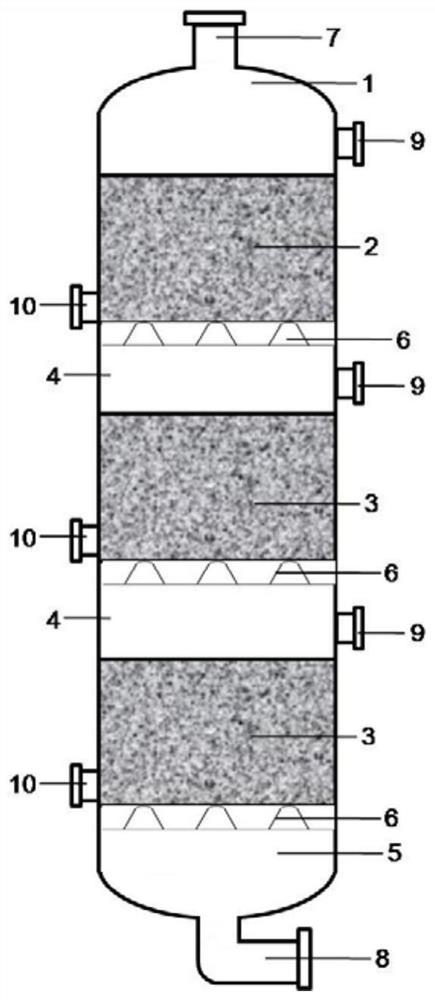

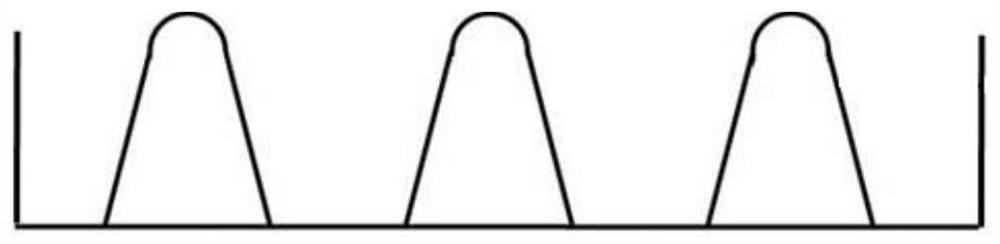

[0048] This embodiment provides a figure 1 Shown is a blast furnace gas hydrolysis tower containing corrugated braces. The height of the blast furnace gas hydrolysis tower is 30m, and the cross section of the main body of the tower body is a circle with a diameter of 5m. Zone 1, pretreatment catalyst module zone 2, two catalyst module zones 3, two transition zones 4 and gas outlet zone 5, wherein catalyst module zones 3 and transition zones 4 are arranged alternately, and pretreatment catalyst module zones 2 and catalyst modules The bottom of zone 3 is provided with corrugated braces 6; the top of the tower is provided with an air inlet 7, the bottom of the tower is provided with an outlet 8, and a loading manhole 9 and a discharge manhole 10 are arranged on the tower body.

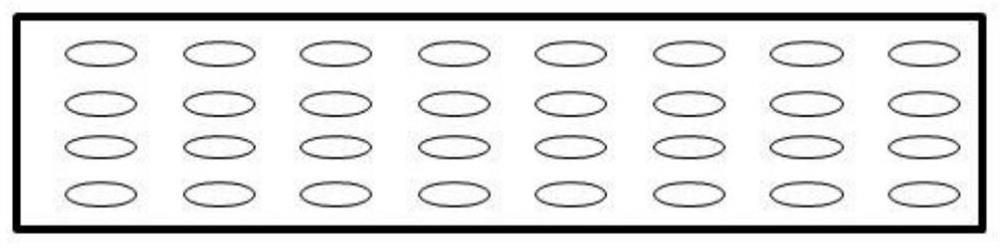

[0049] In this embodiment, the inside of the hydrolysis tower is provided with three corrugated braces 6, and the outer diameter of the corrugated braces 6 is equal to the inner diameter of the main body ...

Embodiment 2

[0052] This embodiment provides a blast furnace gas hydrolysis tower comprising a corrugated support plate, the height of the blast furnace gas hydrolysis tower is 1.5m, the cross section of the main body of the tower is circular with a diameter of 0.5m, and the interior of the main body of the hydrolysis tower is from top to bottom It is divided into the intake area, the pretreatment catalyst module area, the transition area, the catalyst module area and the gas outlet area in sequence, and the bottom of the pretreatment catalyst module area and the catalyst module area are equipped with corrugated plates; the top of the tower is equipped with an air inlet , There is an air outlet at the bottom of the tower, and a loading manhole and a discharging manhole on the tower body.

[0053] In this embodiment, two corrugated braces are arranged inside the hydrolysis tower, and the outer diameter of the corrugated braces is equal to the inner diameter of the main body of the hydrolysis...

Embodiment 3

[0056] The present embodiment provides a blast furnace gas hydrolysis tower comprising corrugated support plates, the height of the blast furnace gas hydrolysis tower is 60m, the cross section of the main body of the tower body is circular with a diameter of 10m, and the inside of the main body of the hydrolysis tower is divided sequentially from top to bottom. It is the intake area, the pretreatment catalyst module area, 9 catalyst module areas, 9 transition areas and the gas outlet area, in which the catalyst module areas and the transition areas are arranged alternately, and the bottoms of the pretreatment catalyst module areas and the catalyst module areas are set There are corrugated braces; the top of the tower is provided with an air inlet, the bottom of the tower is provided with an outlet, and there are loading manholes and unloading manholes on the tower body.

[0057] In this embodiment, the inside of the hydrolysis tower is provided with 10 corrugated braces, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com