Method and system for judging activated carbon heating effect and pre-judging working state of analysis tower

A technology of working status and heating effect, which is applied in the field of activated carbon to treat flue gas, and can solve the problems of inaccurate judgment of the heating effect of activated carbon and blockage of activated carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

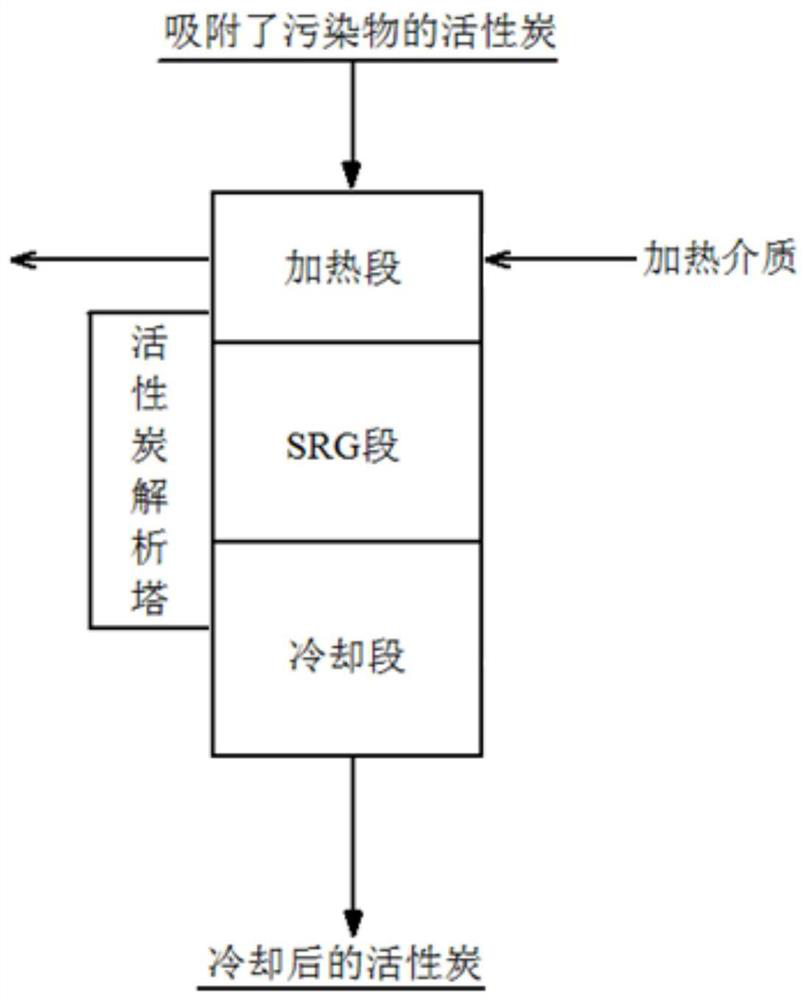

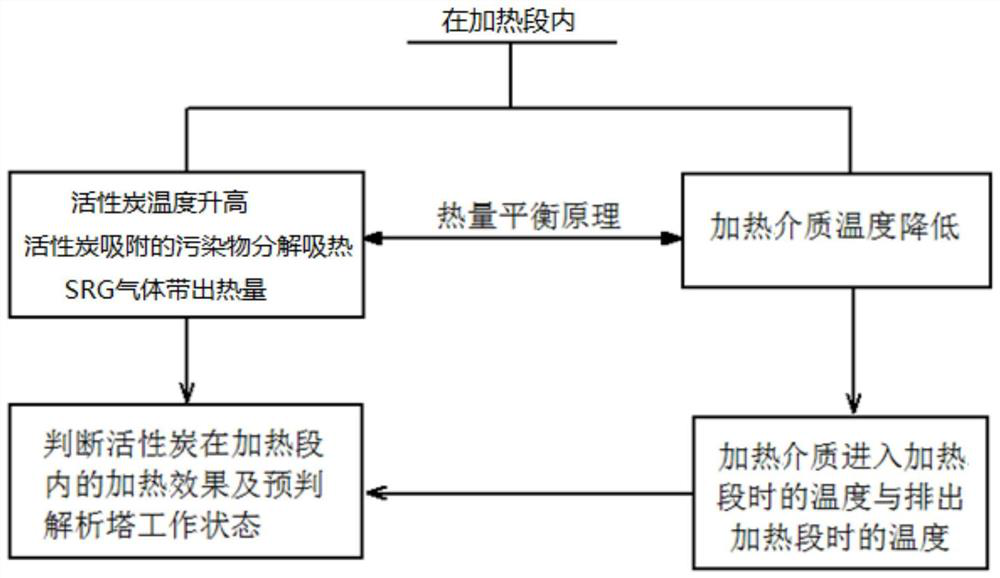

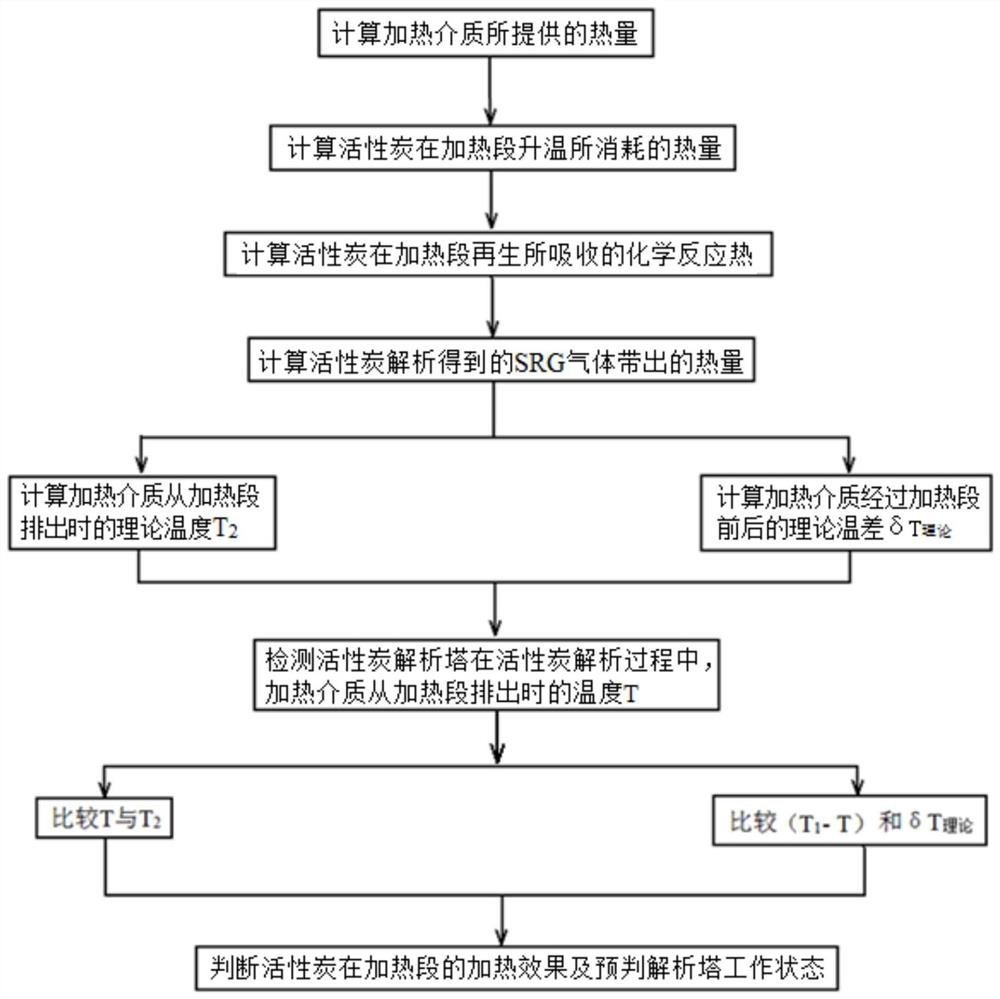

[0123] Such as Figure 7 As shown, a system for judging the heating effect of activated carbon and predicting the working state of the desorption tower includes an activated carbon desorption tower 1 . According to the direction of the activated carbon, the activated carbon desorption tower 1 is provided with a heating section 101, an SRG section 102, and a cooling section 103 sequentially from top to bottom. The sidewall of the SRG section 102 is provided with an SRG gas outlet 104 . The top of the activated carbon analysis tower 1 is provided with an activated carbon feed port, and the bottom of the activated carbon analysis tower 1 is provided with an activated carbon discharge outlet. A heating medium inlet and a heating medium outlet are provided on the side wall of the heating section 101 . The activated carbon inlet of the heating section 101 is provided with a first flow detection device 401 and a first temperature detection device 501 . A second flow detection devi...

Embodiment 2

[0125] Repeat embodiment 1, only the top of the activated carbon feed inlet of activated carbon analysis tower 1 is provided with feed bin, and feed bin bottom is provided with weighing device 3.

Embodiment 3

[0127] Such as Figure 8 As shown, embodiment 2 is repeated, except that the system also includes a control system 7 . The control system 7 and the first flow detection device 401, the first temperature detection device 501, the second flow detection device 402, the second temperature detection device 502, the third flow detection device 403, the sulfur dioxide concentration detection device 6, and the fourth flow detection device 404, the fourth temperature detection device 504, the fifth temperature detection device 505 are connected, and calculate the theoretical temperature difference before and after the heating medium passes through the heating section 101 according to formula (I) or formula (M) in real time, or according to formula (J) or formula ( N) calculate the theoretical temperature when the heating medium is discharged from the heating medium outlet of the heating section 101;

[0128] δT 理论 =T 1 -T 2 =(c 2 q 2 (t 2 -t 1 )+q 3 Cso 2 / 64*δh+c 3 q 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com