Volute casting casting method for nuclear power station

A technology for nuclear power plants and volutes, which is applied to casting molding equipment, casting molds, and casting mold components. It can solve problems such as difficulty in casting molding, and achieve the effects of reducing impurity content, preventing splash turbulence, and internal compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

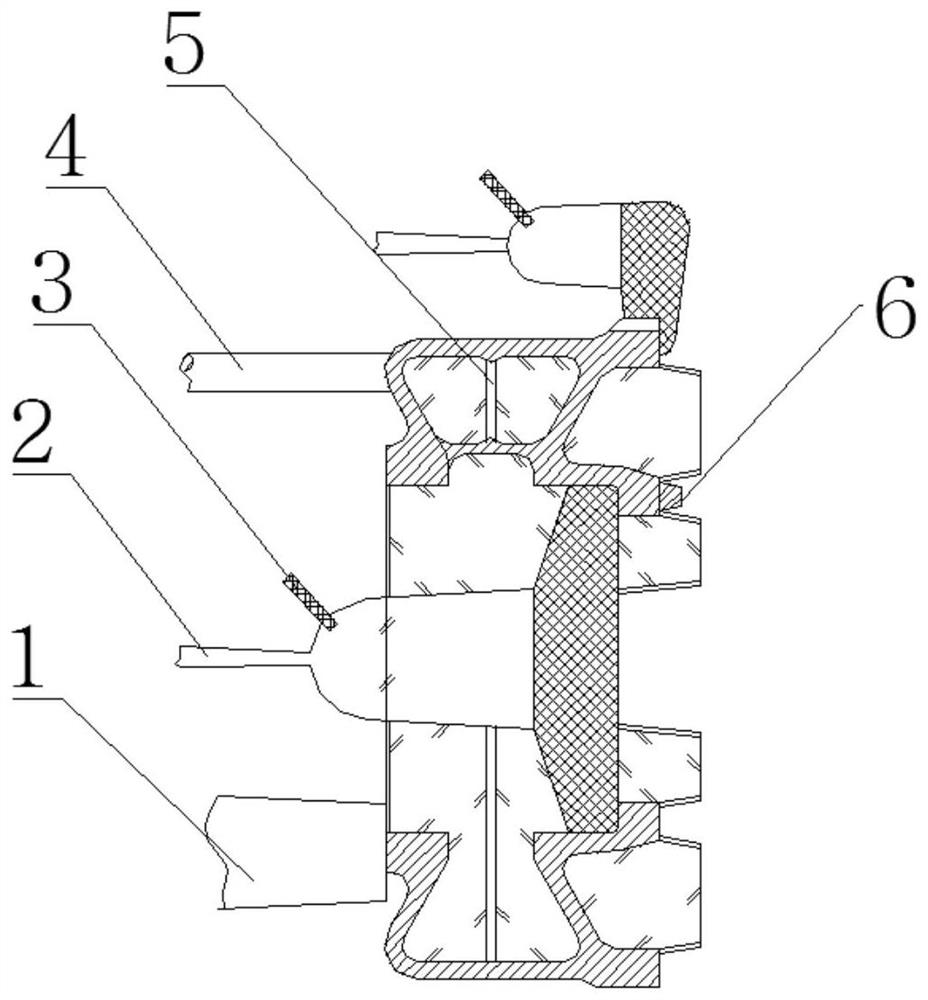

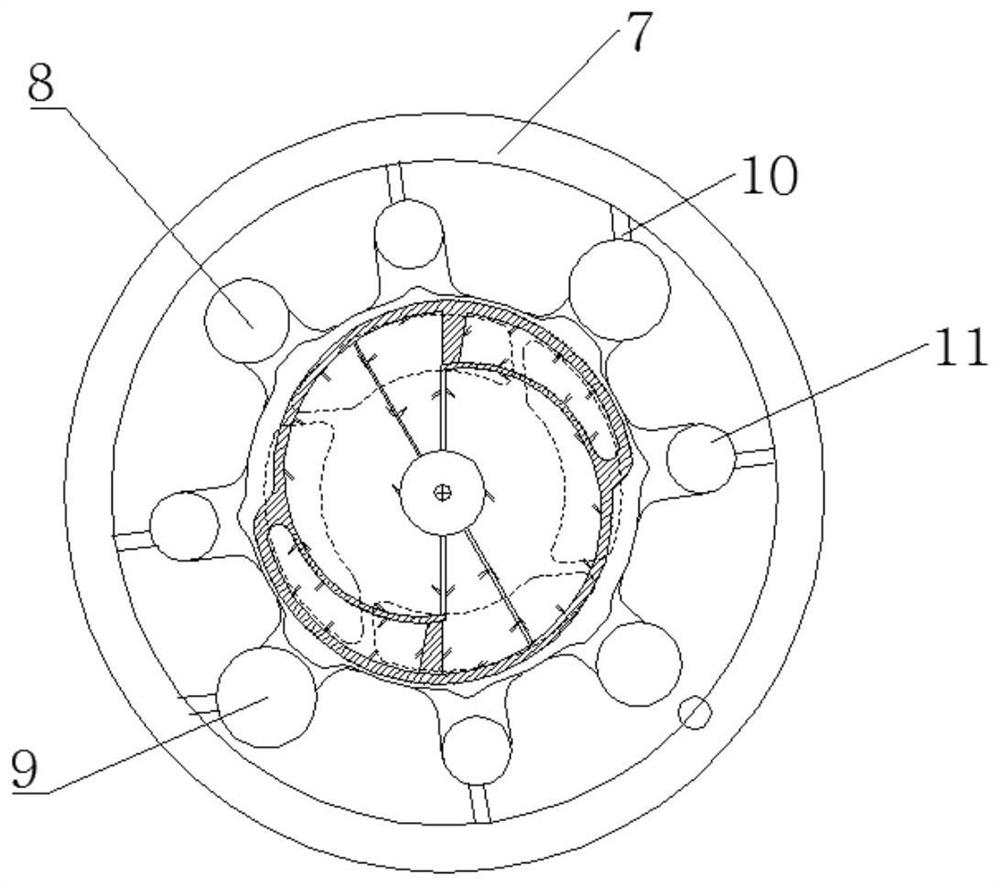

[0020] The reference signs in the drawings of the specification include: No. 1 open riser 1, No. 2 dark riser 2, air hole 3, No. 6 riser 4, core skeleton 5, cold iron 6, annular runner 7, No. 4 dark riser 8, No. 5 dark riser 9, inner runner 10, and No. 3 dark riser 11.

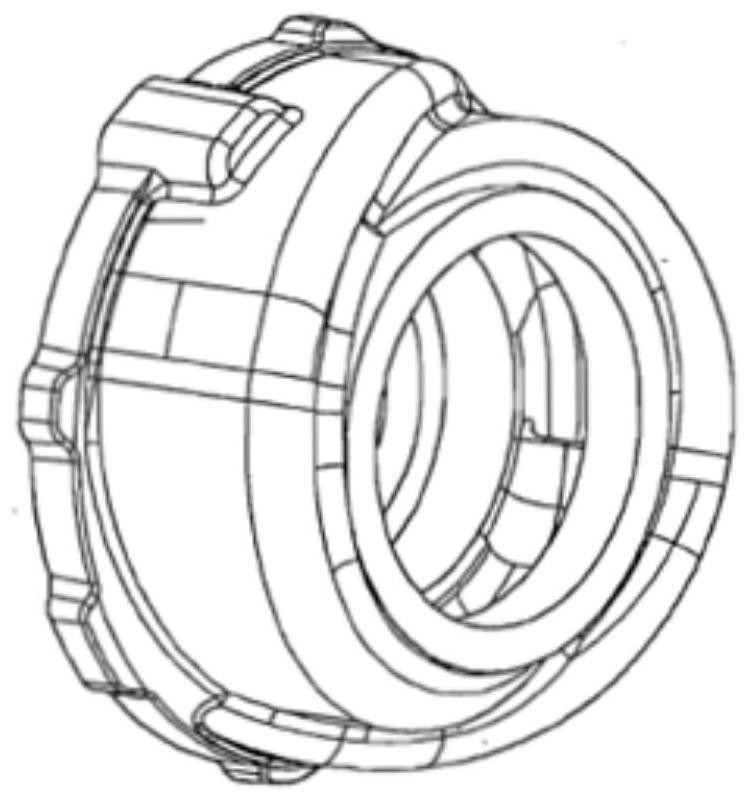

[0021] The specific implementation process is as follows: a method for casting a volute casting for a nuclear power plant, comprising the following steps: Step 1, such as figure 1 , make a model according to the shape of the volute. The model is composed of an upper box plate mold, a lower box plate mold and a sand core sand box mold; use the upper box plate mold and the lower box plate mold to make the outer mold sand mold respectively, and use mud The core sand mold box mold is used to make clay core sand molds, the outer mold sand mold is made of alkali phenolic resin sand, and the mud core sand mold is made of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com