Manufacturing process of annular hot-pressing welding joint for metal pipeline connection

A metal pipe and manufacturing process technology, applied in the field of powder metallurgy technology, can solve the problem of difficulty in obtaining the desired welding interface and welding quality, uncontrollable recombination of heat conduction/heat transfer difference elements, controllable welding process operation stability and process parameters gender issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

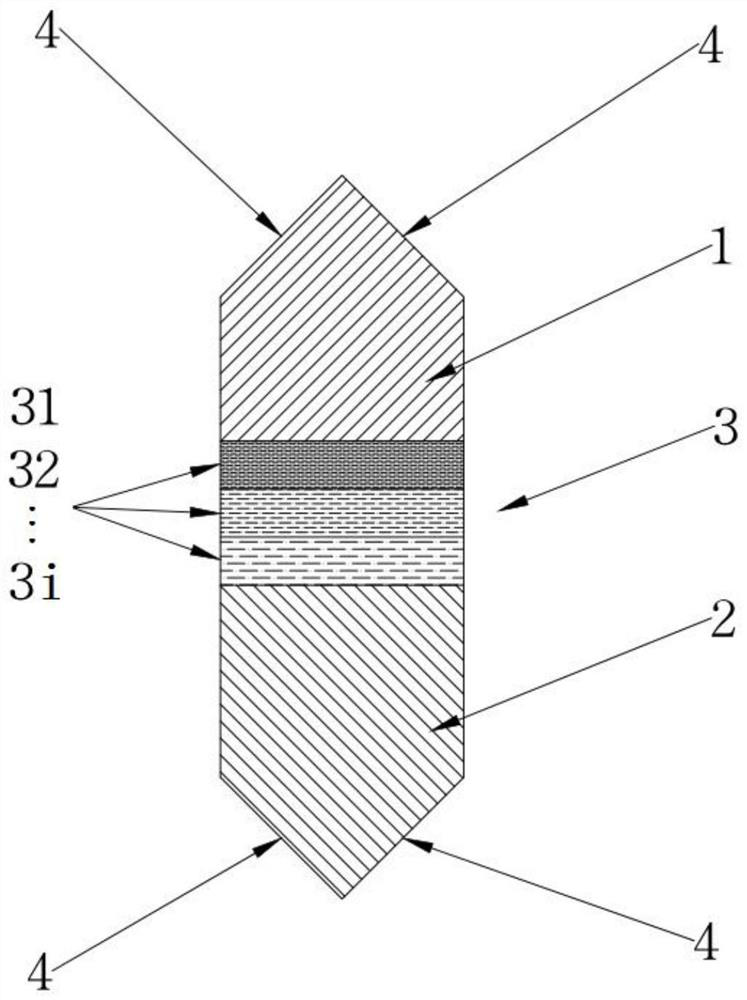

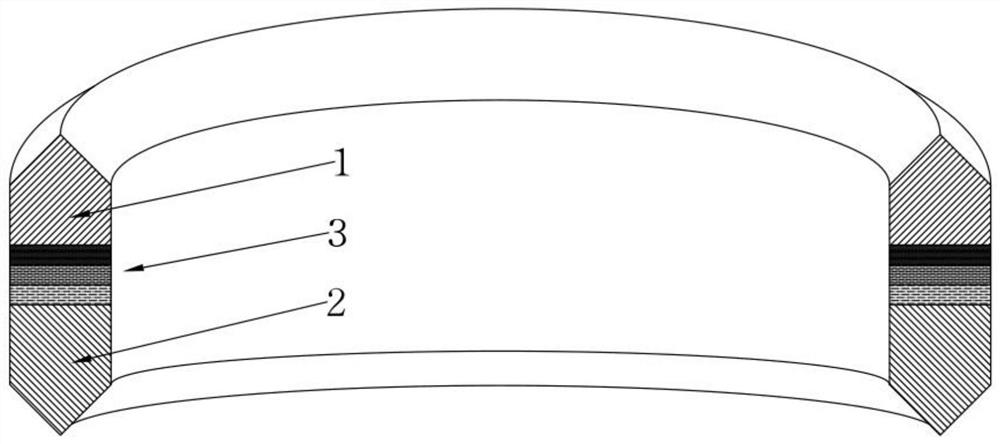

[0031] A manufacturing process of an annular thermocompression welded joint for connecting metal pipes, comprising the following steps:

[0032] Step 1, prepare the first metal ring material 1 of the same or similar material as the first metal pipe to be welded and the second metal ring material 2 of the same or similar material as the second metal pipe to be welded, do not first A metal ring material 1 and the second metal ring material 2 are subjected to half-groove processing;

[0033] Step 2, preparing a first metal powder of the same or similar material as the first metal pipe to be welded and a second metal powder of the same or similar material as the second metal pipe to be welded;

[0034] Step 3, prepare the annular heat-pressing sleeve mold, clamp the second metal ring material 2 prepared in step 1 in the middle of the annular heat-pressing sleeve mold, and make the second metal ring material 2 adhere to the inner wall of the annular heat-pressing sleeve mold or accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com