Double-screwing-direction threaded long screw rod production line and production process thereof

A long screw, double rotation technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of inconvenient screw support of various specifications and lengths, rigid installation of support mechanisms, and impact on processing operations, etc. Adjusting efficiency, improving applicability, and supporting the effect of simple fixing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

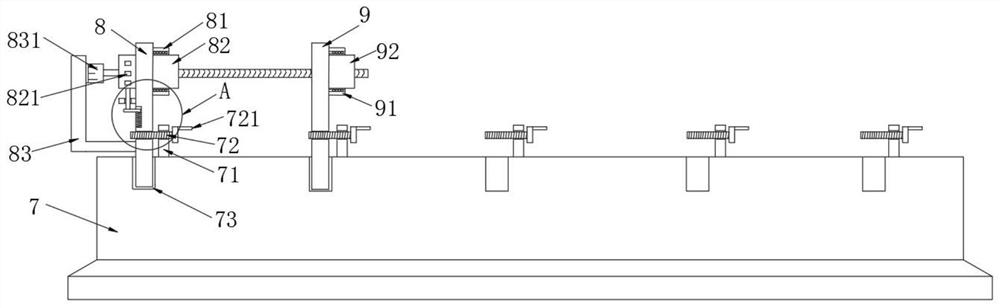

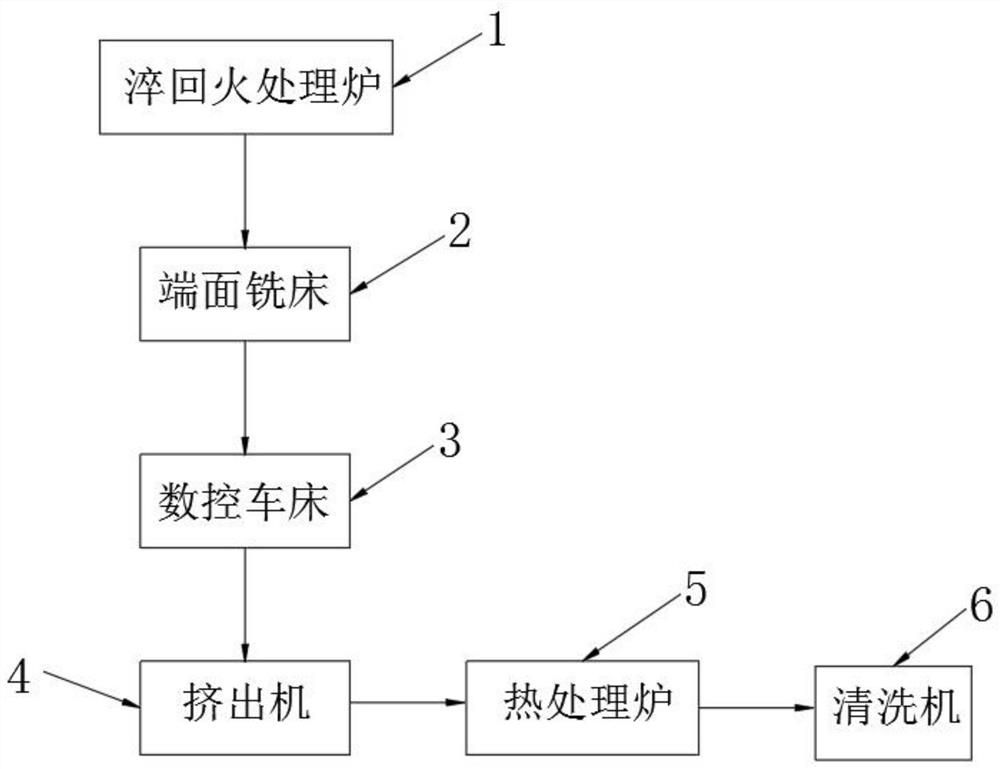

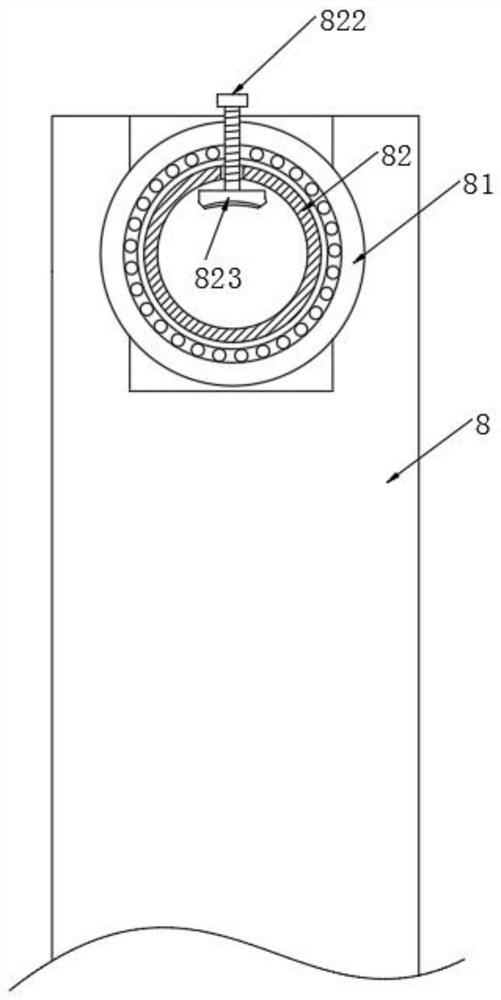

[0032]SeeFigure 1~5 , The present invention provides a technical solution: a double-rotation threaded long screw production line, including a quenching and tempering furnace for pre-heat treatment of the screw 1, an end milling machine for milling the end of the screw 2, used for coarse and fine turning of the screw Round CNC milling machine 3, extruder 4 used to extrude the screw, heat treatment furnace 5 used for final characterization of the screw, cleaning machine 6 used to clean the surface of the screw after processing, and support for the screw during processing Supporting machine base 7, five threaded seats 71 are fixedly connected to the upper end surface of supporting machine base 7, threaded rods 72 are threaded on the inner side of threaded seats 71, and five threaded seats 71 are opened on the upper end surface of supporting machine base 7 Corresponding to the mounting groove 73, the top of the support base 7 is provided with a first mounting seat 8, the first mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com