Recycled asphalt mixture and preparation method thereof

A technology for old asphalt mixture and recycled asphalt, applied in the field of recycled asphalt mixture and its preparation, can solve the problems of performance degradation and high addition ratio of old asphalt mixture, reduce surface energy, reduce compaction temperature, and improve water damage resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Recycled asphalt mixture, in parts by weight, comprising 65 parts of new aggregate, 35 parts of old asphalt mixture, 2 parts of mineral powder, 5 parts of new asphalt and 1.05 parts of asphalt rejuvenating agent, wherein the new aggregate is graded basalt or Limestone material; old asphalt mixture is graded old asphalt mixture; new asphalt is base asphalt, SBS modified asphalt or rubber asphalt.

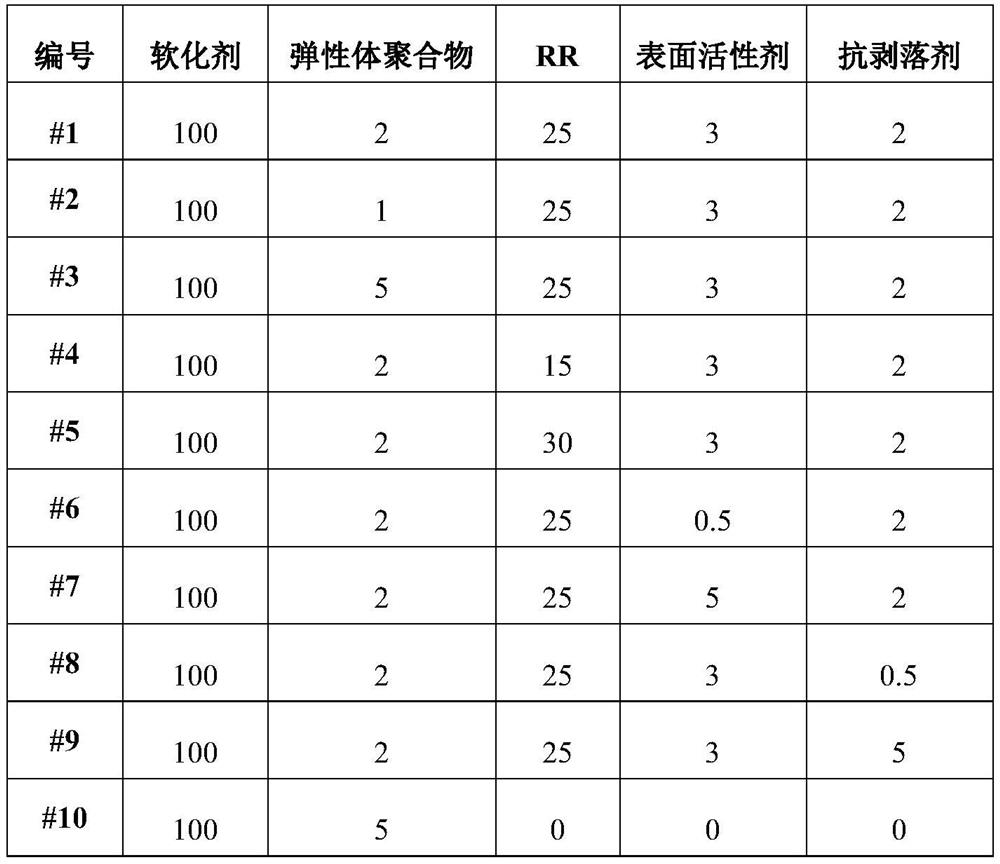

[0033] Asphalt regeneration agent, in parts by weight, comprising 100 parts softener, 1-5 parts elastomeric polymer, 15-30 parts linearized reactive rubber (RR), 0.5-5 parts surfactant and 0.5-5 parts anti-stripping wherein the softening agent is one of soybean oil, dioctyl phthalate, naphthenic oil, reduced third-line oil or rich aromatic hydrocarbons; the elastomeric polymer is one of SBS, SBR, SIS or butadiene rubber The surfactant is one of sodium lauryl sulfonate, glyceryl stearate, polyoxyethylene alkylamine or long-chain fatty alcohol polyoxyethylene ether; the anti-str...

Embodiment 2~12

[0055] Examples 2-12 and Comparative Examples 1-4:

[0056] The difference from Example 1 is that, as shown in Table 3 below, the content of the components is different from the number of the asphalt rejuvenating agent used.

[0057] Table 3 is the composition table of Examples 1-12 and Comparative Examples 1-4

[0058] new aggregate old asphalt mixture Mineral powder new asphalt Asphalt regeneration agent Example 1 65 35 2 5 1.05#1 Example 2 65 35 2 5 1.05#2 Example 3 65 35 2 5 1.05#3 Example 4 65 35 2 5 1.05#4 Example 5 65 35 2 5 1.05#5 Example 6 65 35 2 5 1.05#6 Example 7 65 35 2 5 1.05#7 Example 8 65 35 2 5 1.05#8 Example 9 65 35 2 5 1.05#9 Example 10 75 25 1 7 0.75#1 Example 11 55 45 3 4 1.35#1 Example 12 55 45 2 6 2.25#1 Comparative Example 1 65 35 2 5 1.05#10 Comparative Example 2 65 35 2 5 1.05#11 Comparativ...

Embodiment 13

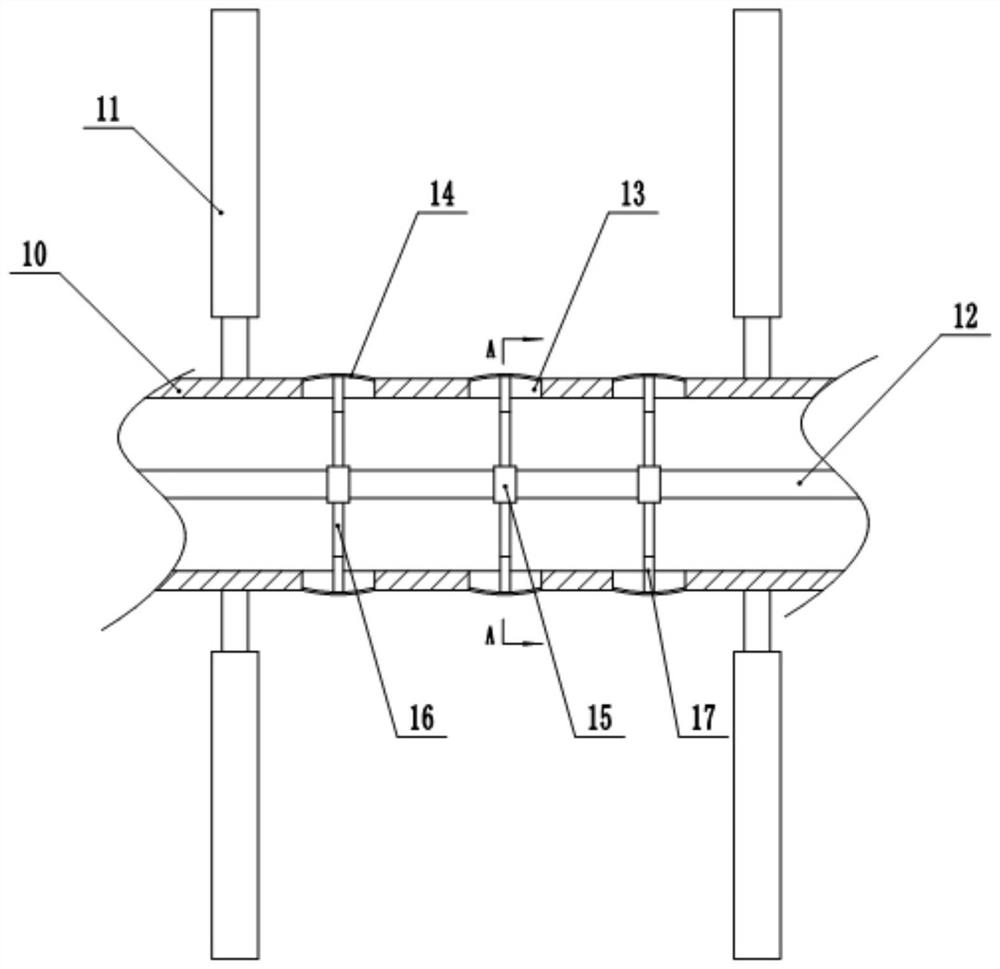

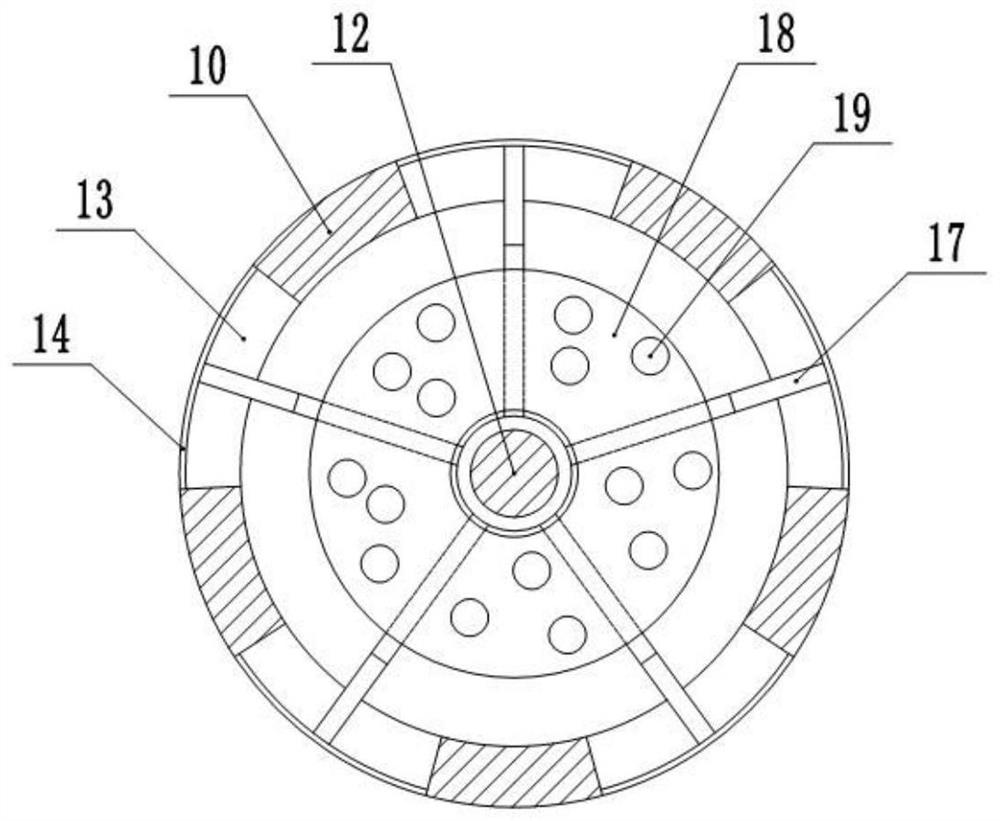

[0060] The difference from Example 1 is that the step S3 of the asphalt regenerating agent and the step S3 of regenerating the asphalt mixture both use special stirring equipment, combined with figure 1 and figure 2 As shown, the special stirring equipment includes a horizontally fixed stirring drum, an inlet is provided at the left end of the stirring drum, an outlet is provided at the right end, and a stirring shaft 10 is rotatably connected in the stirring drum, wherein the stirring shaft 10 is hollow and arranged on two sides of the stirring shaft 10. Both ends are connected with pipes through rotary joints, and several stirring blades 11 are fixed on the stirring shaft 10, and the heating medium (gas, water, liquid metal, etc.) flows through the stirring shaft 10 through the pipes, thereby heating the stirring shaft 10 and stirring blades 11, A driving mechanism for driving the stirring shaft 10 to rotate is also provided.

[0061] A connecting rod 12 is slidably connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com