High-temperature-resistant anticorrosive paint and preparation method thereof

A technology for anti-corrosion coatings and high temperature resistance, which is applied in the direction of anti-corrosion coatings, fire-proof coatings, chemical instruments and methods, etc. It can solve the problems of cumbersome production process, reduced production effect and high labor cost of high-temperature-resistant anti-corrosion coatings, so as to improve scraping efficiency, The effect of improving uniformity and improving the effect of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

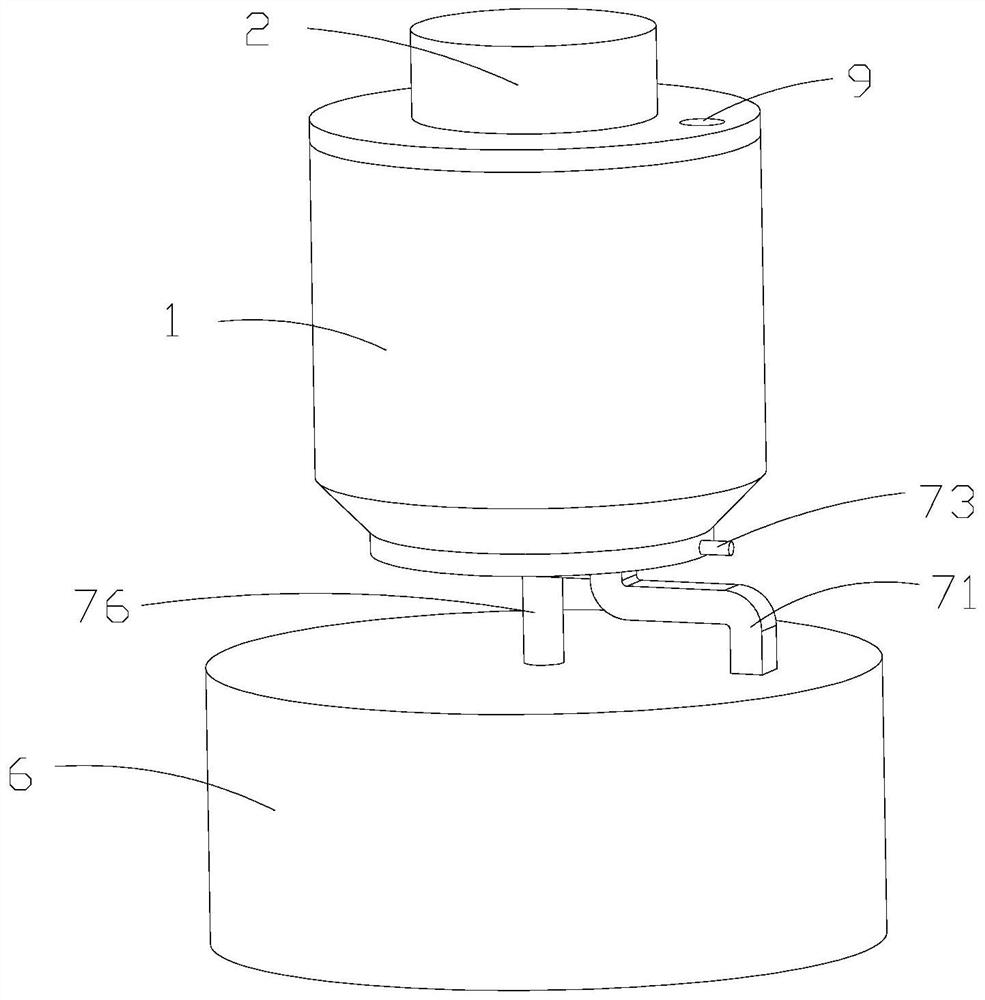

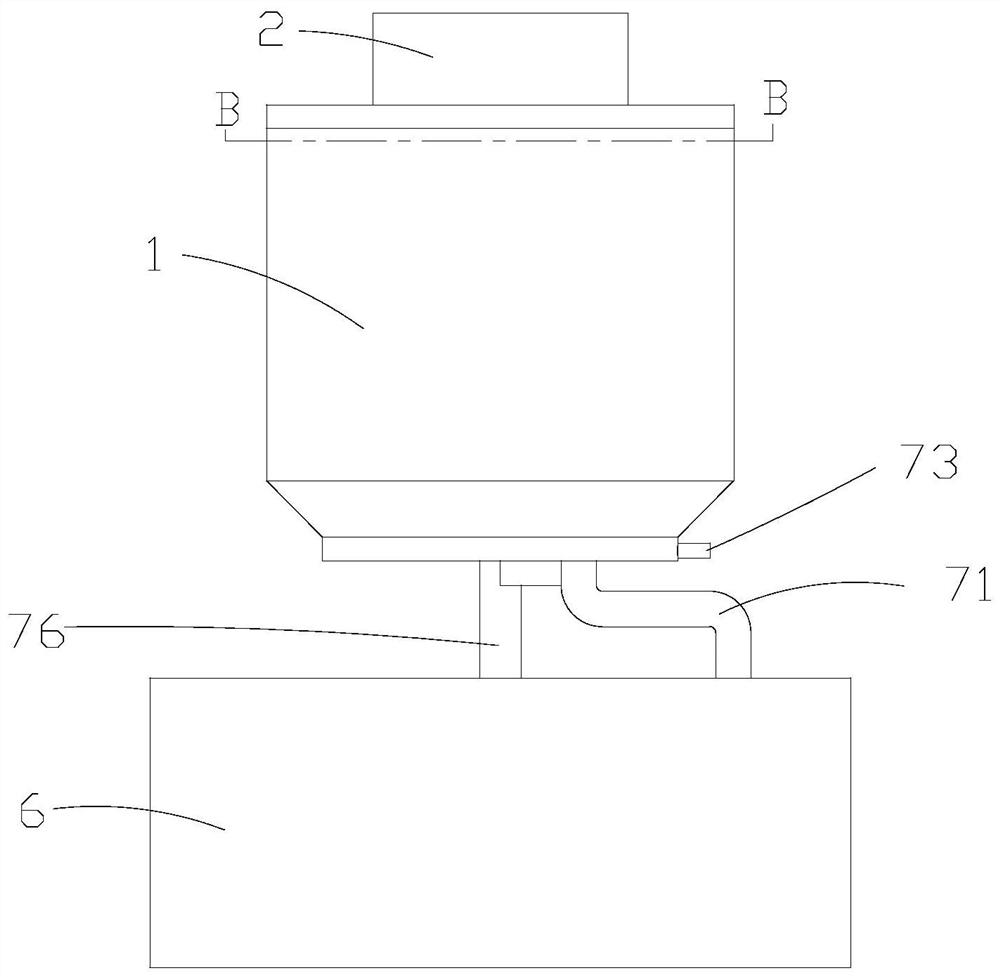

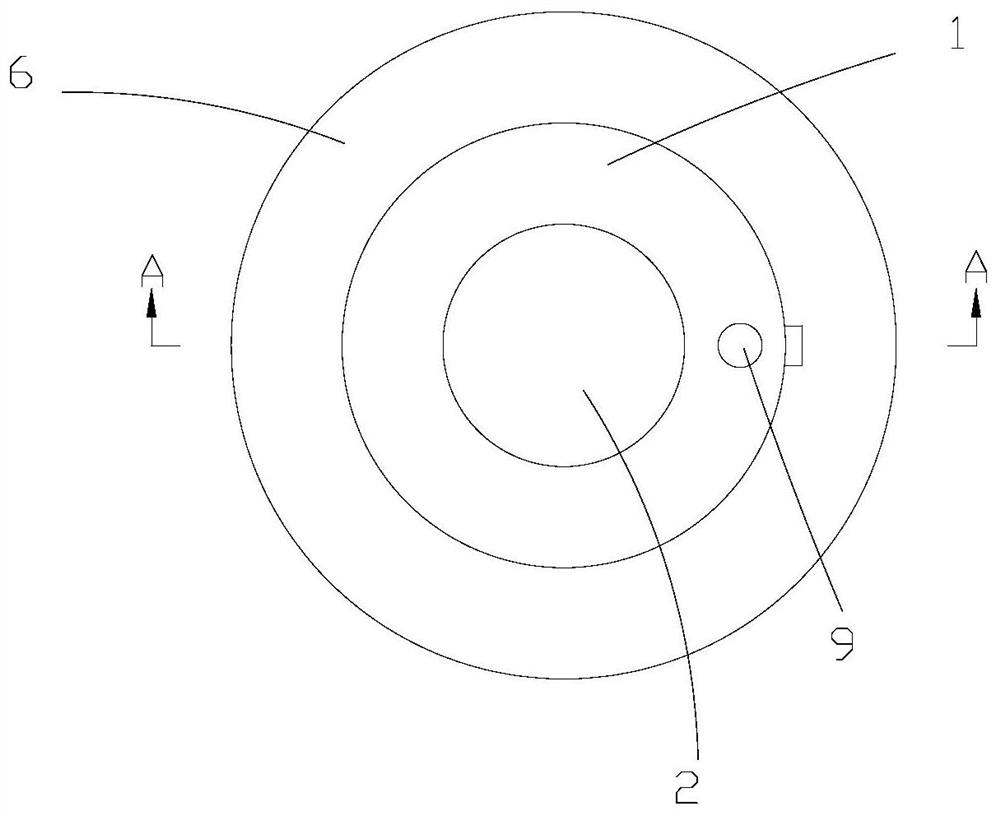

[0037] Such as Figure 1-11 Shown, a kind of high temperature resistant anticorrosion paint and preparation method thereof, comprises the following steps:

[0038] a. Base material preparation: mix 30 parts of siloxane and 11 parts of alkyd modified siloxane evenly to obtain base material;

[0039] b. Mixing: put the base material formed in a into 38 parts of methane, then add 12.5 parts of zinc powder and 1.5 parts of aluminum powder;

[0040] c. Finished material: Put the mixed liquid obtained in b into the reactor, heat to 360°C, react for 7 hours, and obtain the coating after polymerization;

[0041] The agitator in b includes a main body 1, a motor 2, a feed port 9, an ultrasonic resonator 3, a rotating ring 4, a stirring device 5, a reaction kettle 6, and a discharge device 7; the stirring device 5 includes a stirring frame 41, The first V-shaped plate 42, the splitter plate 43, the second V-shaped plate 44, and the scraping mechanism 8; the motor 2 is arranged on the ...

Embodiment 2

[0049] A high-temperature-resistant anti-corrosion coating and a preparation method thereof, comprising the following steps:

[0050] a. Base material preparation: mix 33 parts of siloxane and 13.5 parts of alkyd modified siloxane evenly to obtain base material;

[0051] b. Mixing: Put the base material formed in a into 41 parts of methane, then add 41.5 parts of zinc powder and 3.5 parts of aluminum powder;

[0052] c. Finished material: Put the mixed liquid obtained in b into the reactor, heat to 380°C, react for 8 hours, and obtain the coating after polymerization;

Embodiment 3

[0054] A high-temperature-resistant anti-corrosion coating and a preparation method thereof, comprising the following steps:

[0055] a. Base material preparation: mix 31.5 parts of siloxane and 12.5 parts of alkyd modified siloxane evenly to obtain base material;

[0056]b. Mixing: put the base material formed in a into 40 parts of methane, then add 27.5 parts of zinc powder and 2 parts of aluminum powder;

[0057] c. Finished material: Put the mixed liquid obtained in b into the reaction kettle, heat it to 370°C, react for 7.5 hours, and obtain the coating after polymerization;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com