Construction method of movable shaped stair formwork

A construction method and stair technology, which are applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of heavy repair work, poor stabilization effect, and large dimensional error in the decoration stage. Achieve the effect of good appearance quality, regular shape and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

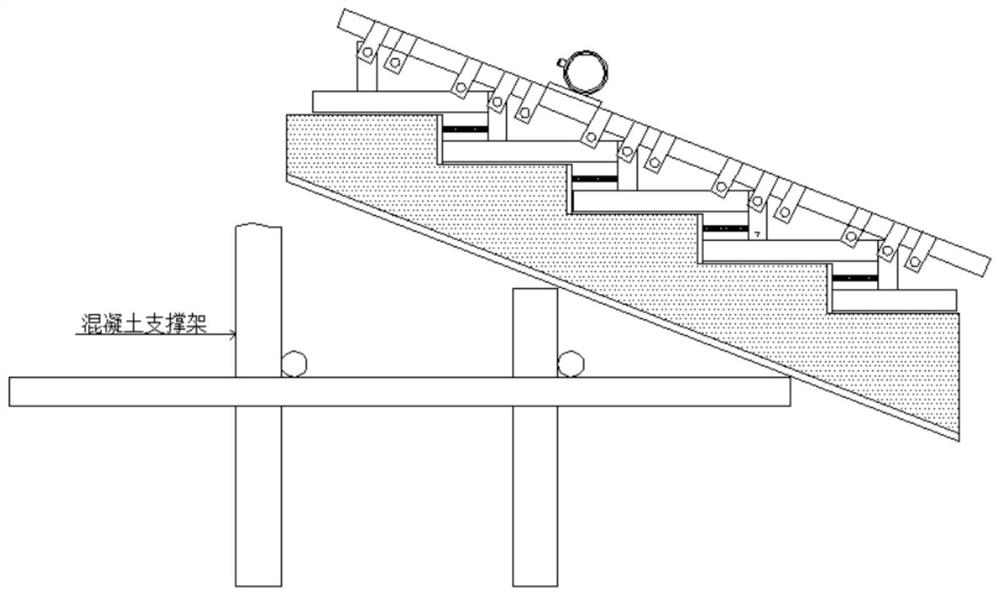

[0044]Compared with the traditional staircase formwork construction method of the present invention, the movable staircase formwork support formwork construction method:

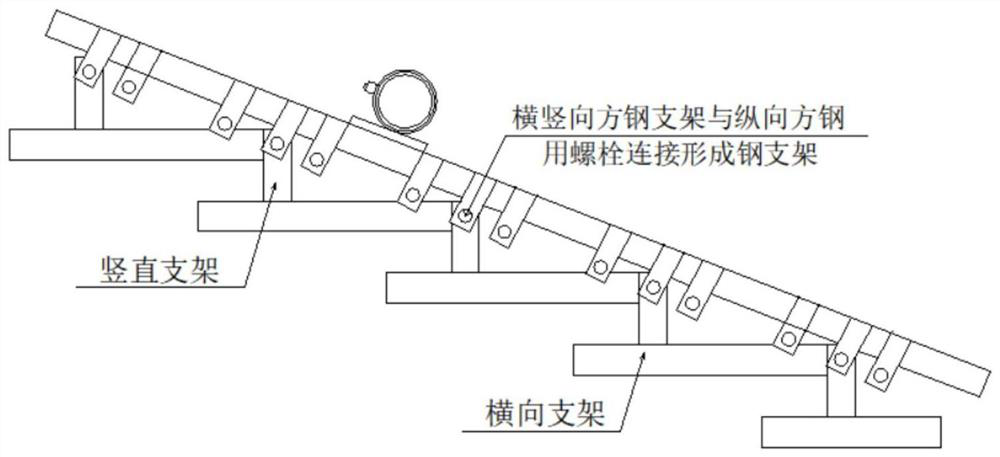

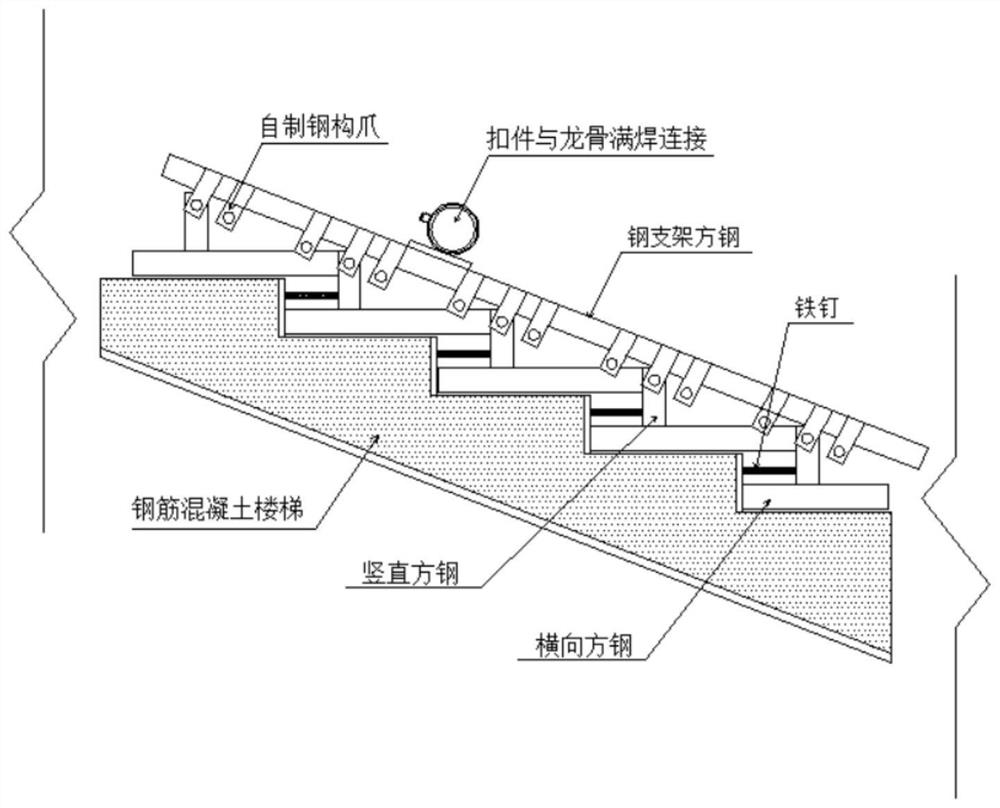

[0045]1. The construction is convenient and the operation is simple. After the stair bottom form and the step formwork are supported, only the steel bracket is hoisted in place and the bolts are tightened to complete the entire staircase formwork combination.

[0046]2. By adjusting the horizontal displacement of the movable and shaped stair steel frame, it can be applied to stairs with various heights and steps.

[0047]3. Reduce the disposal of construction waste, which is beneficial to environmental protection.

Embodiment 2

[0049]Compared with the traditional staircase formwork construction method of the present invention, the movable staircase formwork support formwork construction method:

[0050] Movable staircase supporting method Traditional stair formwork method Bearing capacity / kpa 30002200 Time for picking and polishing / h 06 Assembly and disassembly time / h410

[0051]From the above table, we can get: according to the present invention, the movable shaped staircase support formwork construction method is used to cast the staircase, which not only ensures the forming quality of the staircase concrete, but also reduces the scratching and repair work before the decoration process, saving social resources and reducing In order to reduce the impact of construction waste on the environment, it has a positive role in protecting natural resources, ecological environment, and reducing costs and increasing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com