Packaging method of quantum dot film, packaged quantum dot film and application

A technology of quantum dot film and encapsulation method, which is applied in the direction of chemical instruments and methods, electrical components, circuits, etc., and can solve the problems of film luminous performance degradation, increased final product cost, and a lot of work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

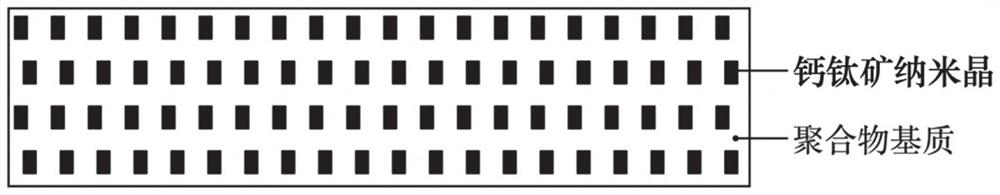

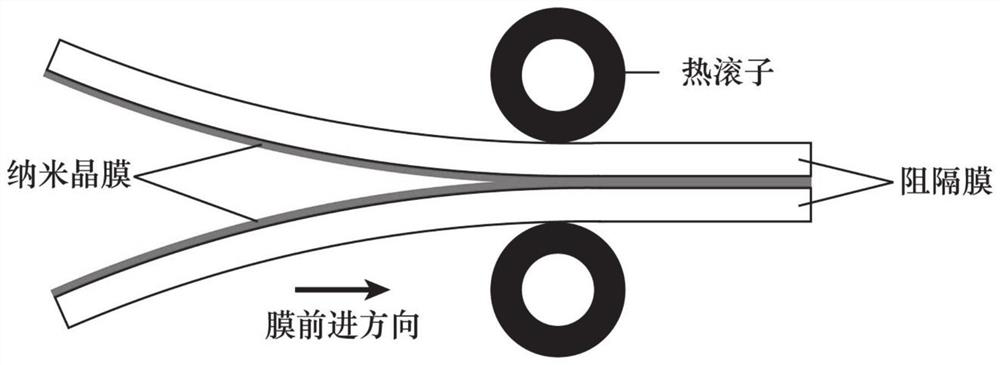

Embodiment 1

[0127] Take two sheets coated with CH on one side 3 NH 3 PbBr 3 (MAPbBr 3 ) EVOH barrier film of nanocrystal / PVDF composite luminescent film (this composite luminescent film is quantum dot film, the mass percentage of quantum dot and polymer is 1wt%, the thickness of composite luminescent film is 100 μ m), barrier film thickness is 5 μ m, (The perovskite nanocrystal / polymer composite film structure is shown in figure 1 ), the two barrier films were coated with MAPbBr 3 One side of the nanocrystalline / PVDF composite luminescent film is placed opposite, and then slowly passes through the laminating machine (such as figure 2 shown). The roller temperature of the laminating machine is set to 160°C, and the hot pressing processing time is 5s. The two films are hot-pressed by a laminating machine to achieve glue-free packaging, and the peeling force between the films after packaging is >5N. The luminescence peak of the film after hot-press packaging is located at 524nm, and ...

Embodiment 2

[0130] Take one side coated with CH(NH 2 ) 2 PbBr 3 (FAPbBr 3 ) Nanocrystalline / PE composite luminescent film (this composite luminescent film is a quantum dot film, the mass percentage of quantum dots and polymer is 20wt%, and the thickness of the composite luminescent film is 0.1 μm) Nylon barrier film (barrier film thickness is 1500 μm ) and another nylon barrier film (the thickness of the barrier film is 1500 μm), the barrier film was coated with MAPbBr 3 One side of the nanocrystalline / PE composite luminescent film is placed opposite to another barrier film, and then slowly passes through the laminating machine. The roller temperature of the laminating machine is set to 80°C, and the hot pressing processing time is 15s. The two films are hot-pressed by a laminating machine to achieve glue-free packaging, and the peeling force between the films after packaging is >3N.

Embodiment 3

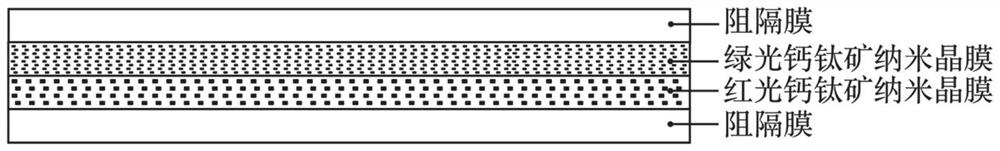

[0132] Take one side coated with green MAPbBr 3 Quantum dot / EVA composite luminescent film (the mass percentage of quantum dot and polymer is 10wt%, the thickness of composite luminescent film is 20 μ m) SiO 2 Barrier film (the thickness of the barrier film is 1000 μm) and the other side is coated with red CsPbI 3 / RbPbI 3 Nanocrystalline / EVA composite luminescent film (the mass percentage of quantum dots and polymer is 15wt%, and the thickness of the composite luminescent film is 20 μm) SiO 2 Barrier film (the thickness of the barrier film is 1000 μm). Then slowly through the laminating machine. The roller temperature of the laminating machine is set to 40°C, and the hot pressing processing time is 10s. The two films are hot-pressed by a laminating machine to realize glue-free packaging, and the peeling force between the films after packaging is >10N (the structure after packaging is as follows image 3 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com