Electric vehicle composite power supply system energy management method

A composite power supply and energy management technology, applied in electric vehicles, vehicle energy storage, battery circuit devices, etc., to achieve the effect of power distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing:

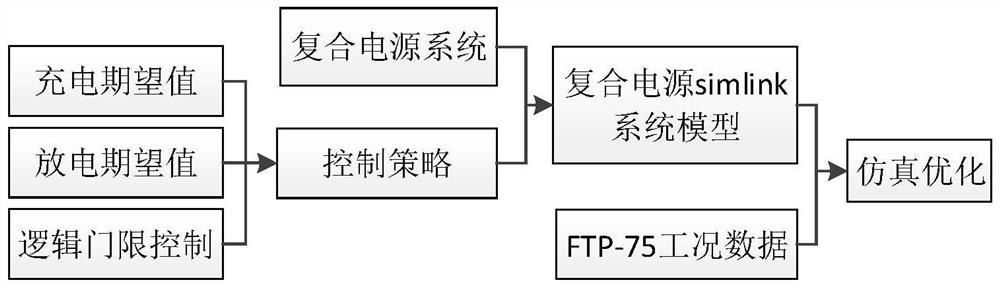

[0039] An energy management method for an electric vehicle composite power supply system, such as figure 1 shown, including the following steps:

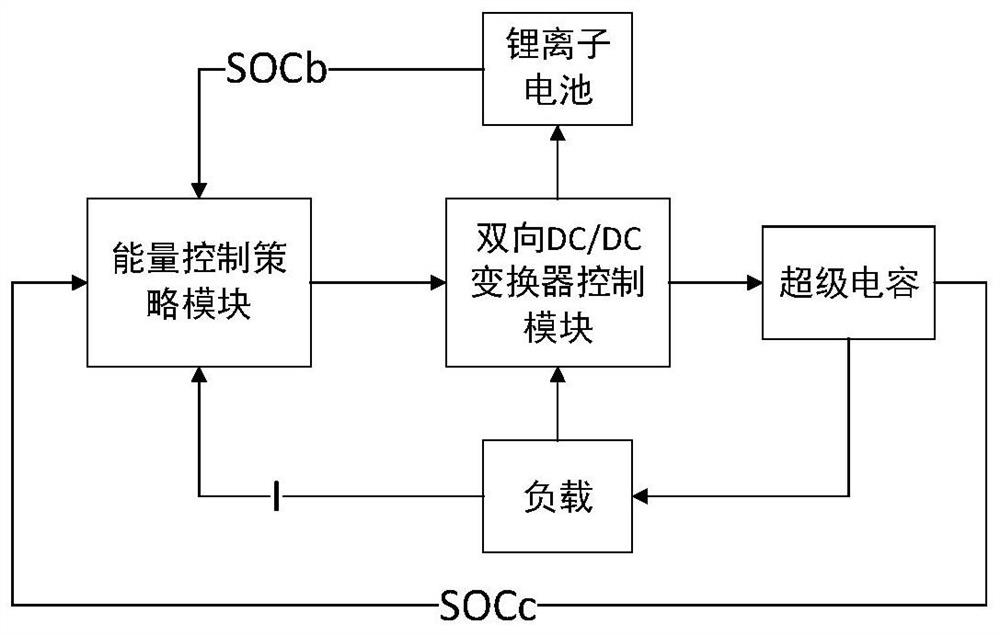

[0040] S1. Establish a composite power system model composed of supercapacitors, lithium-ion batteries, bidirectional DC / DC converter control modules and energy control strategy modules, such as figure 2 shown.

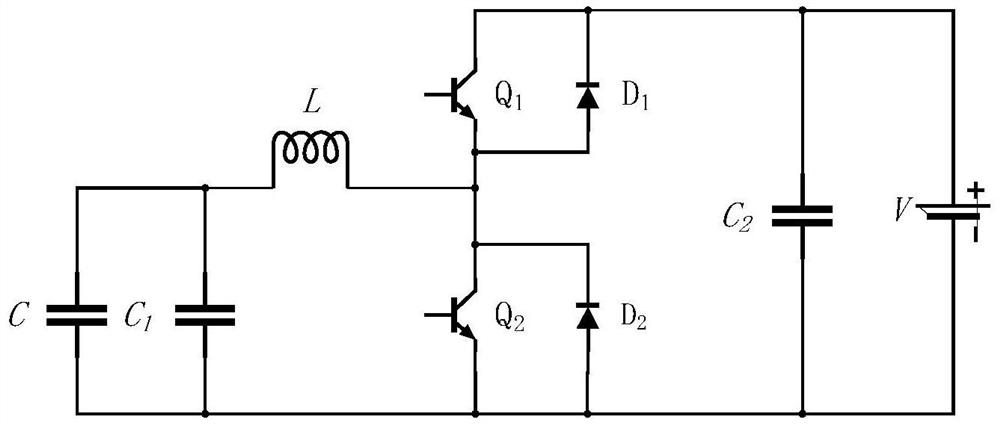

[0041] Among them, the supercapacitor is connected in series with the DC / DC converter, and then connected to the DC bus in parallel with the lithium-ion battery to form a composite power circuit structure, such as image 3 shown. Through the control of the DC / DC converter, the direction of energy transmission of the lithium-ion battery and the supercapacitor can be changed, so that they can work together to provide the required power for the motor or perform energy recovery. The DC / DC converter is divided into boost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com