Inorganic-organic composite living cell scaffold as well as preparation method and application thereof

A living cell and organic technology, applied in the field of inorganic-organic composite bioink-based living cell scaffold and its preparation, inorganic-organic composite living cell scaffold and its preparation, can solve secondary wounds, insufficient donor sources, Immunological rejection and other issues, to achieve the effects of enhanced contact, good proliferation, and freedom of migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] SrSiO 3 Preparation of microparticles:

[0060] Weigh 2.116g Sr(NO 3 ) 2 and 2.842g Na 2 SiO 3 9H 2 O in two beakers, respectively measure 50mL deionized water into the two beakers, stir until the crystals are completely dissolved; use a dropper to dissolve the Sr(NO 3 ) 2 The solution was slowly added dropwise to Na 2 SiO 3 In the solution, stir while adding dropwise until the two are completely mixed; measure about 50mL of absolute ethanol and pour it into it, seal the mouth of the cup, and stir for more than 30min; pour the mixture into a 50mL polytetrafluoroethylene hydrothermal reaction kettle, put Oven, hydrothermal reaction at 160°C for 8 hours; after the hydrothermal treatment is over, pour off the supernatant after the solution is cooled, collect the white precipitate in the lower layer, wash it with deionized water for 3 times, ultrasonic for 10 min each time, wash with absolute ethanol for 3 times, and ultrasonically for each time 10min; put the powd...

Embodiment 2

[0063] Preparation of SS-GAM inorganic-organic composite bioink

[0064] Weigh 0.7g of gellan gum powder into a jar, add 25mL of sterilized deionized water, put it in a water bath and stir at 90°C for more than 30min until the powder is completely dissolved; turn off the heating switch and let the solution naturally Cool down; when the temperature of the solution drops below 84°C, weigh 0.4g high-viscosity sodium alginate, 0.7g methylcellulose and a certain amount (0g, 0.014g, 0.035g, 0.07g four kinds of content) SrSiO 3 Add micron particles into it, stir continuously to make it fully mixed; the temperature of the high-viscosity fluid to be mixed is lowered to room temperature, and irradiated with ultraviolet light for about 1 hour to obtain sterile GAM, 2SS-GAM, 5SS-GAM, 10SS-GAM Four kinds of gradient SrSiO 3 content of inorganic-organic composite bioinks.

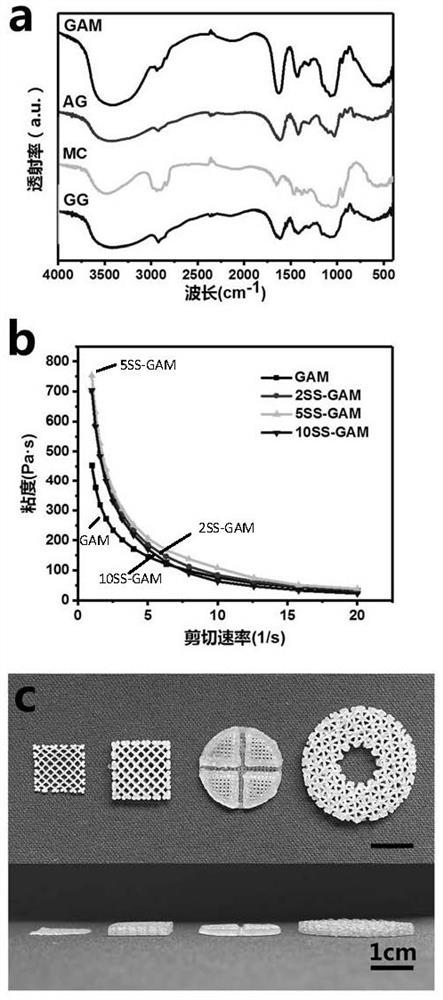

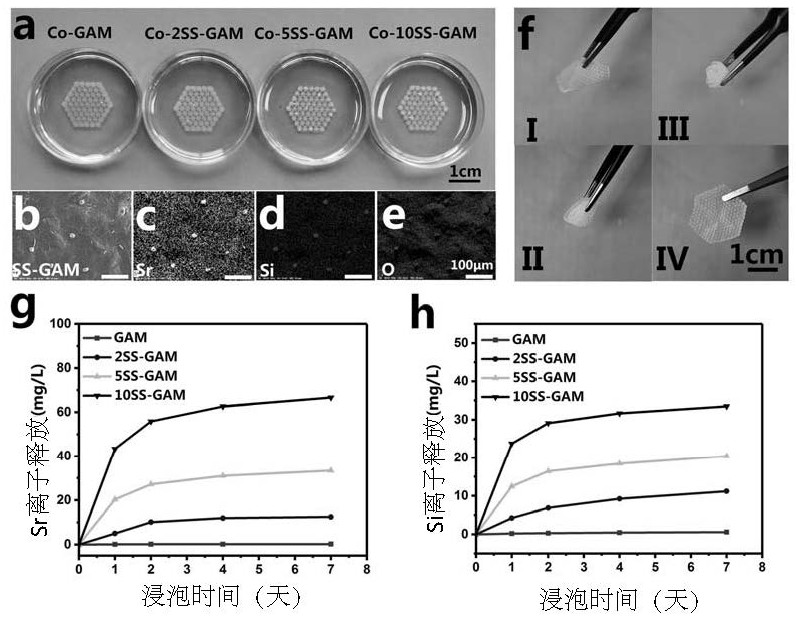

[0065] figure 2 It was shown that GAM hydrogel is the product of physical combination of gellan gum, sodium algina...

Embodiment 3

[0067] Preparation of SS-GAM Inorganic-Organic Composite Scaffold for Living Cells

[0068] Step 1: Preparation of gradient SS-GAM inorganic-organic composite bioink

[0069] Weigh 0.7g of gellan gum powder into a jar, add 25mL of deionized water, put it in a water bath and stir at 90°C for more than 30min until the powder is completely dissolved; turn off the heating switch and let the solution cool down naturally; When the temperature of the solution drops below 84°C, weigh 0.4g of high-viscosity sodium alginate, 0.7g of methylcellulose and a certain amount (0g, 0.014g, 0.035g, 0.07g four gradient contents) of SrSiO 3 Add micron particles into it, stir continuously to make it fully mixed; the temperature of the high-viscosity fluid to be mixed is lowered to room temperature, and irradiated with ultraviolet light for about 1 hour to obtain sterile GAM, 2SS-GAM, 5SS-GAM, 10SS-GAM Four kinds of gradient SrSiO 3 content of inorganic-organic composite bioinks.

[0070] Step 2:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com