Ship multi-mechanical arm welding spot cooperative welding method based on QMIX reinforcement learning algorithm

A technology of reinforcement learning and manipulators, applied in the direction of manipulators, welding equipment, auxiliary welding equipment, etc., can solve the problems that are not involved, sensors are taken into consideration, affect the accuracy of path planning and the effectiveness of anti-interference, so as to reduce labor and time The cost and method are simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

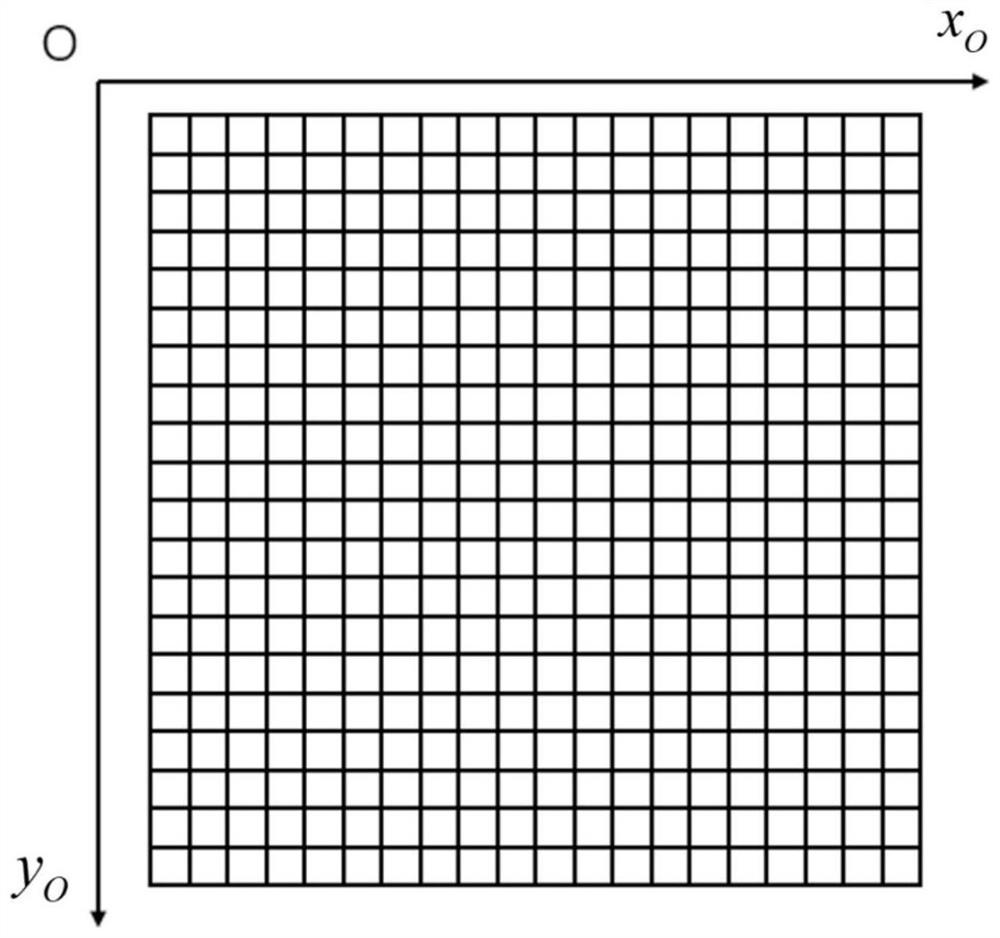

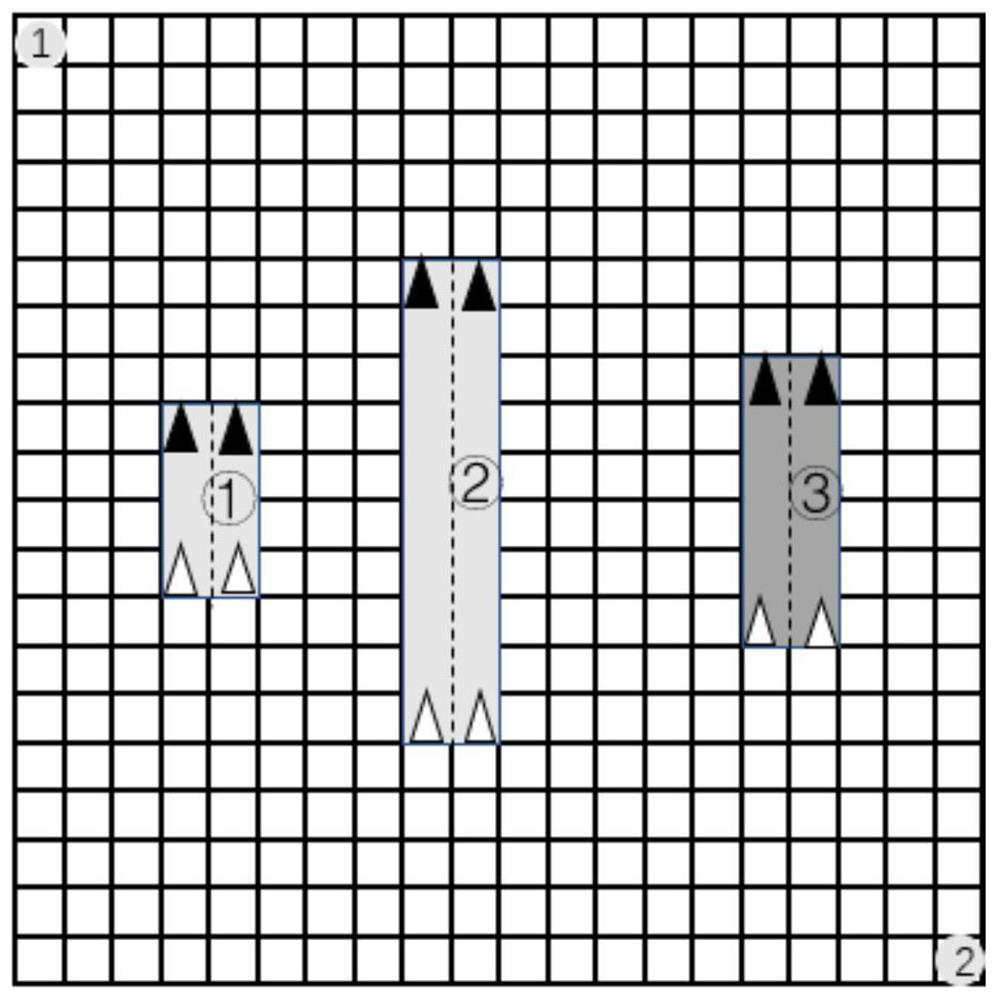

[0046] The invention is a cooperative welding method for multi-manipulator welding joints of a ship based on a QMIX reinforcement learning algorithm, and is especially suitable for welding environments including cooperative welding requirements, limited sensing information, collision avoidance and the like. First, consider two robotic arms J 1 ,J 2 Collaborative welding learning is performed in a 20x20 grid world and this environment is modeled in python software. According to the actual welding scene, an independent welding area with a size of 2x4 and 2x10 and a collaborative welding area with a size of 2x8 are respectively established, and their starting coordinates in the grid world are ((4,9),(5,9)), ((9,6),(10,6)), ((16,8),(17,8)).

[0047] Two robotic arms J 1 ,J 2 In the process of learning and training, due to the limitation of information exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com