Automatic assembling equipment and assembling method for gear assembly

An automatic assembly and gear set technology, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing installation difficulty, gear sets cannot be installed stably, and adding steps for zero adjustment, so as to avoid steric hindrance , reduce the impact, increase the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

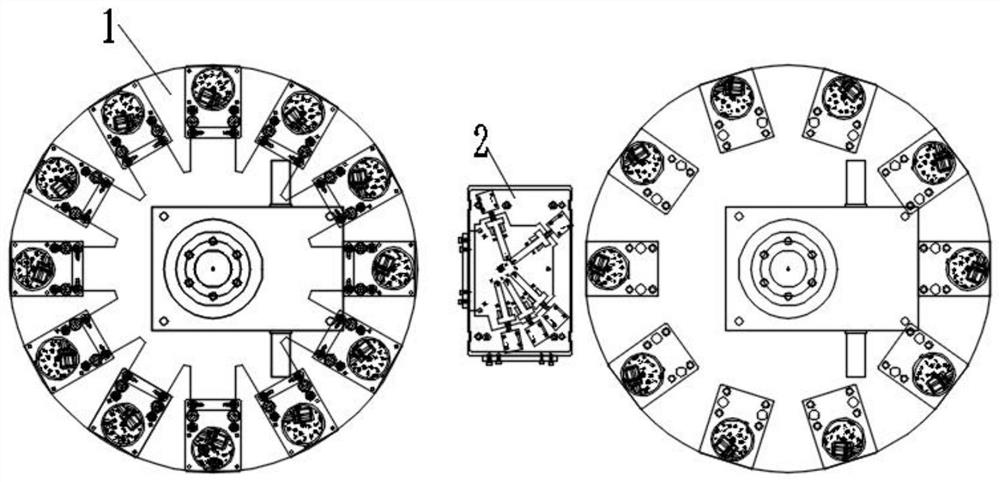

[0043] Embodiment 1: refer to figure 2, an automatic assembly equipment for gear assemblies. The gear set pre-installation device 1 is arranged on one side of the gear set assembly device 2. The gear set pre-installation device 1 is a rotating disk with a ring structure, and the rotating disk is driven by a motor. Twelve stations are arranged on the disc, including installation stations and positioning stations for ten gears in the gear train. The installation station of the gear adopts the method of vibrating plate and conveyor belt. The gear moves to the end of the conveyor belt. After pneumatic clamping, the gear is transferred to the rotating disk. The pneumatic clamping and positioning station make the gear accurately placed on the rotating disk. superior.

[0044] After the processing of the gear set pre-installation device 1, ten gears in the gear set are placed on the rotating disk, and the ten gears are separated from each other. Some of the gears are moving gears, ...

Embodiment 2

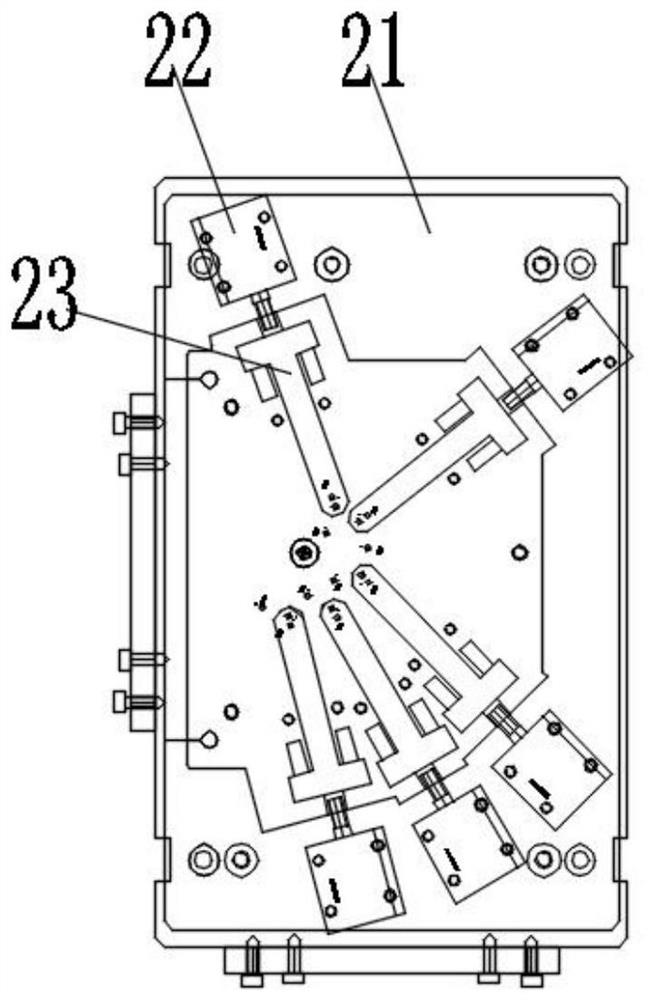

[0054] Embodiment 2: Combining with the basis of Embodiment 1, the difference lies in that in this embodiment, the gear set assembly device 2 is integrated with the clamping device group, that is, the clamping device is provided with a slide rail, and the corresponding clamping gear of the moving gear The head is slidingly connected with the slide rail, and the driving device 22 on the gear assembly device drives the clamping head to move along the slide rail.

[0055] The steps of the automatic assembly method of the gear assembly in this embodiment are as follows:

[0056] S1. The gear set pre-installation device 1 is used to combine the gears into a gear set according to the timing relationship, and the gears in the gear set are in a disengaged state;

[0057] S2. The whole disengaged gear set is clamped by the clamping device, and the clamping head in the clamping device is driven by the driving device 22 to drive the moving gear in the horizontal direction, so that the ge...

Embodiment 3

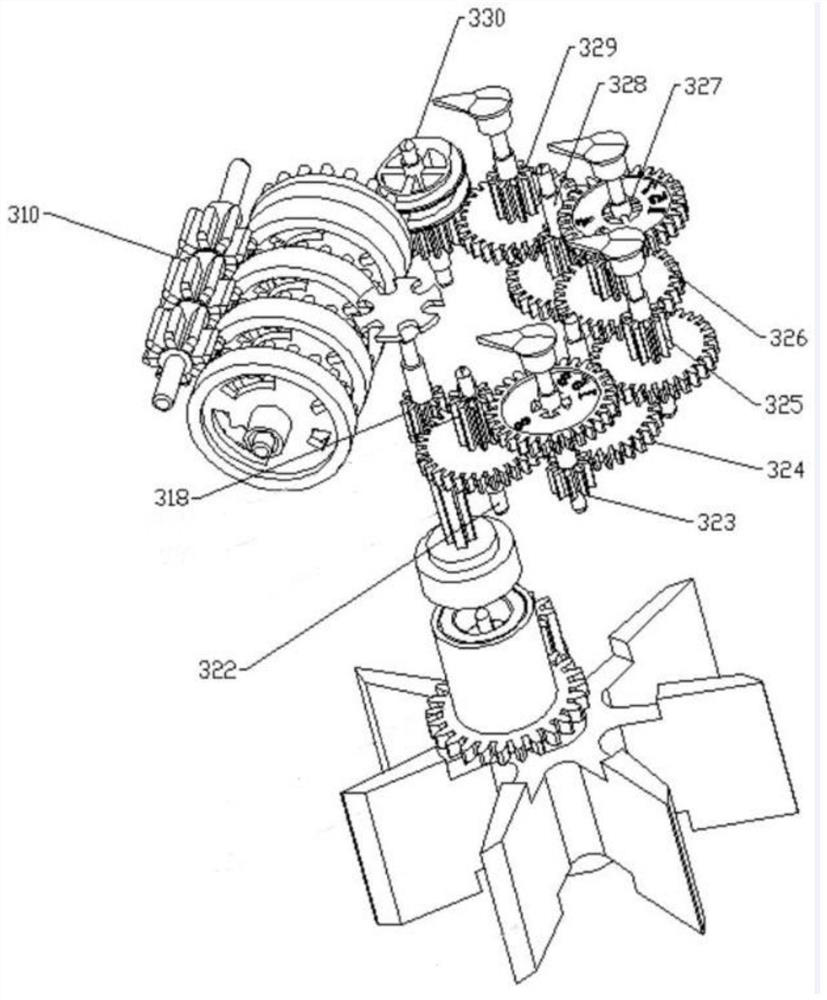

[0064] This embodiment is different from Embodiment 1 in that each gear in the gear set in this embodiment is a moving gear, that is, the moving gears are divided into two groups, the first gear 322, the second gear 323, the fourth gear 325, The sixth gear 327 and the eighth gear 329 form the first group, and the second sun gear 218 , the third gear 324 , the fifth gear 326 , the seventh gear 328 and the worm gear 330 form the second group. When the gear set assembly device 2 assembles the gear sets in the horizontal direction, the driving device 22 drives the first set of movable gears and the second set of movable gears to move toward each other until the entire gear set is meshed.

[0065] In some examples, the second sun gear 318, first gear 322, second gear 323, and third gear 324 are grouped into a first group, and the fourth gear 325, fifth gear 326, and sixth gear 327 are grouped into a second group. Two groups, the seventh gear 328, the eighth gear 329 and the worm ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com