Heat-conducting silica gel and continuous production process and equipment thereof

A technology of heat-conducting silica gel and production technology, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of single cylinder and low labor intensity, and achieve the effects of improving compatibility, reducing labor intensity, and fully mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

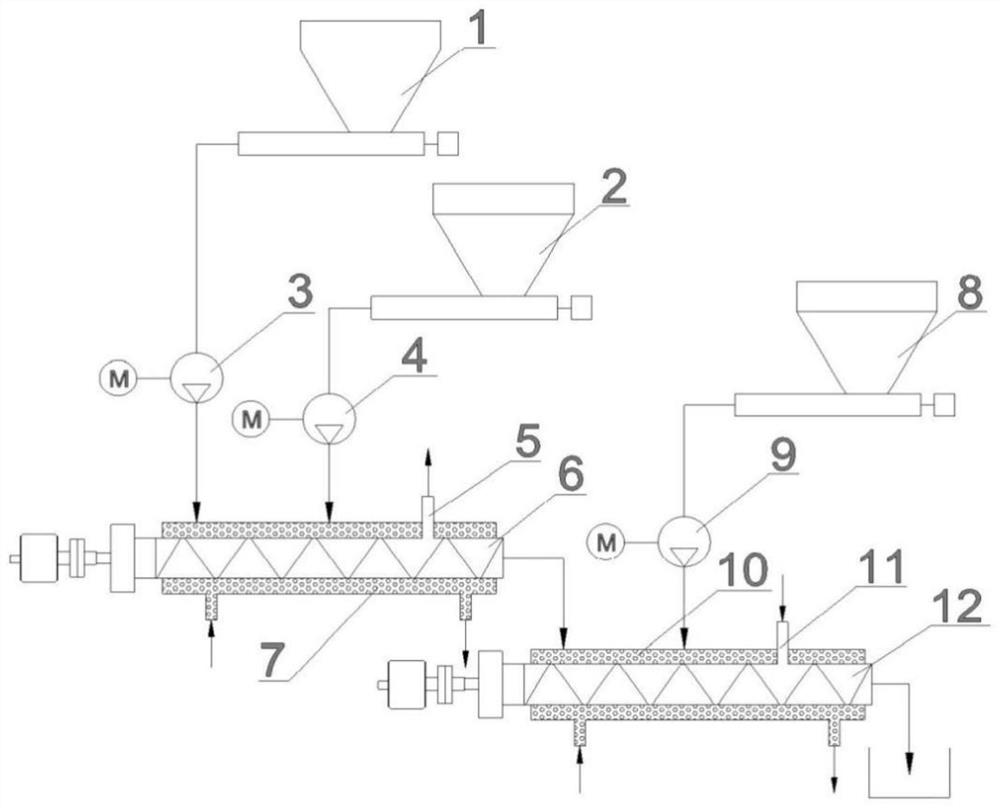

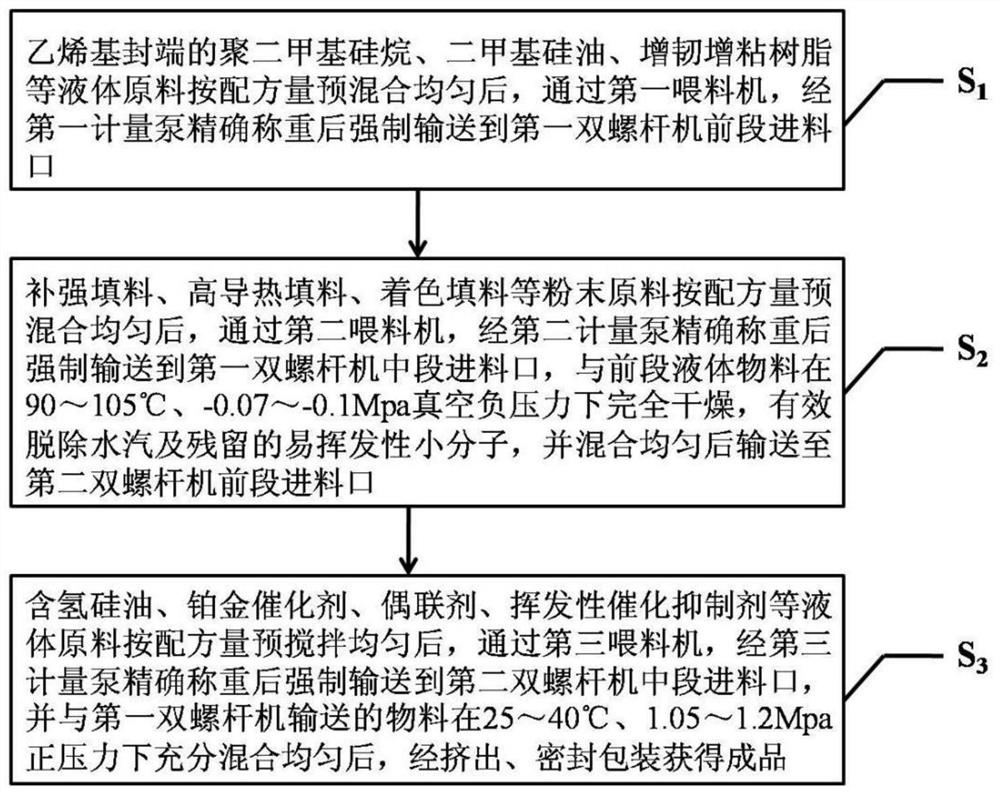

[0043] Such as figure 1 , figure 2 As shown, a continuous production equipment for heat-conducting silica gel of the present invention includes a first twin-screw machine and a second twin-screw machine, and the first terminal outlet of the first twin-screw machine is connected to the second end of the second twin-screw machine. The feeding port in the front section is connected, and also includes the first feeder, the second feeder, the third feeder, the first metering pump, the second metering pump, and the third metering pump,

[0044] The first feeder and the first metering pump are sequentially connected to the first front-stage feeding port of the first twin-screw machine;

[0045] The second feeder and the second metering pump are sequentially connected to the first middle section feed port of the first twin-screw machine;

[0046] The third feeder and the third metering pump are sequentially connected to the second middle stage feed port of the second twin-screw mac...

Embodiment 2

[0060] The difference between this embodiment and embodiment 1 is:

[0061] The length-to-diameter ratios of the first twin-screw machine and the second twin-screw machine are both 12:1.

[0062] In terms of mass fraction, the ratio of each raw material is as follows: 45 parts of vinyl-terminated polydimethylsilane resin, 7 parts of dimethyl silicone oil, 12 parts of toughening and tackifying resin, 15 parts of reinforcing filler, 11 parts of high thermal conductivity filler, 5 parts of hydrogen-containing silicone oil, 1 part of platinum catalyst, 2 parts of volatile catalyst inhibitor, and 2 parts of coupling agent.

[0063] The toughening and tackifying resin is reactive liquid nitrile rubber, the reinforcing filler is fumed titanium dioxide, and the high thermal conductivity filler is an average particle diameter D 50 It is ultrafine silicon carbide of 10-30um, the volatile catalytic inhibitor is ethynyl cyclohexanol, and the coupling agent is vinyltrimethoxysilane.

[0...

Embodiment 3

[0066] The difference between this embodiment and embodiment 2 is:

[0067] The length-to-diameter ratio of the screw of the first twin-screw machine is 9:1, and the length-to-diameter ratio of the screw of the second twin-screw machine is 6:1.

[0068] In terms of mass fraction, the proportions of each raw material are as follows: 42 parts of vinyl-terminated polydimethylsilane resin, 4 parts of dimethyl silicone oil, 10 parts of toughening and tackifying resin, 8 parts of reinforcing filler, 30 parts of high thermal conductivity filler, 3.5 parts of hydrogen-containing silicone oil, 0.5 parts of platinum catalyst, 1 part of volatile catalytic inhibitor, and 1 part of coupling agent.

[0069] The toughening and tackifying resin is reactive liquid nitrile rubber, the reinforcing filler is precipitated silica, and the high thermal conductivity filler is an average particle diameter D 50 The volatile catalyst inhibitor is 2-methyl-3-butyn-2-ol, and the coupling agent includes v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com