Pervious recycled concrete resistant to chloride ion erosion and preparation method thereof

A technology for recycling concrete and chloride ions, applied in the field of concrete, can solve the problems of poor resistance to chloride ion corrosion, cracks at the interface, corrosion of concrete steel bars, etc., and achieves the effects of enhancing compactness, reducing cracks, and reducing interface effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

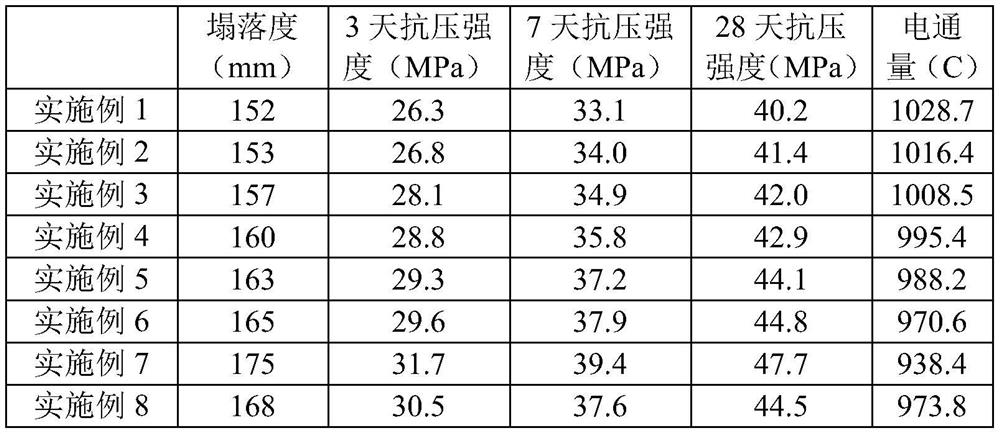

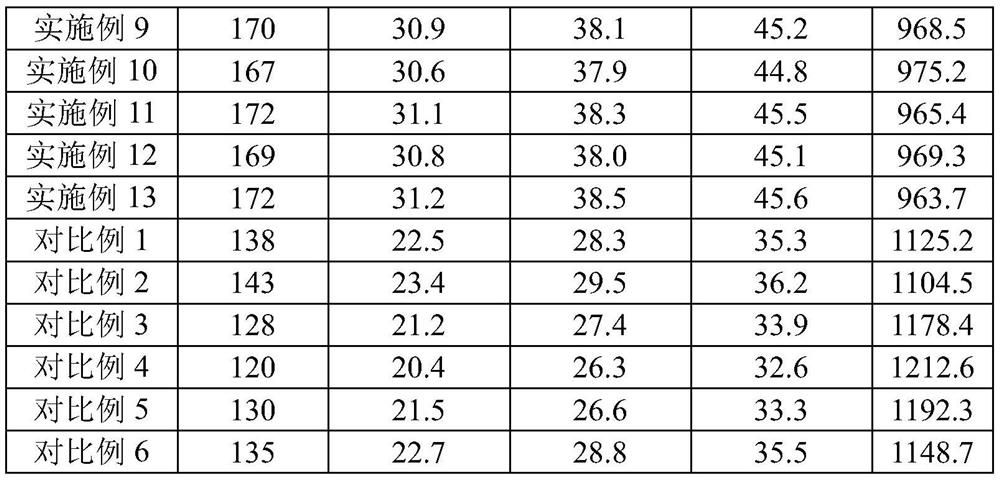

Examples

preparation example 1

[0037] The preparation method of recycled aggregate is as follows:

[0038] 1) cleaning the waste concrete surface to remove impurities on the waste concrete surface;

[0039] 2) Crushing and grading the cleaned waste concrete, and then further ball milling the broken waste concrete to obtain particles with a particle size of 0.1-0.2 mm;

[0040] 3) heat-treating the ground particles at 650°C for 1 hour;

[0041] 4) Soak the heat-treated particles in a calcium hydroxide solution with a mass fraction of 20 wt%, and the solid-to-liquid ratio of the particles to the lye is 1:4;

[0042] 5) After soaking, dry to obtain recycled aggregate.

preparation example 2

[0044] The preparation method of recycled aggregate is as follows:

[0045] 1) cleaning the waste concrete surface to remove impurities on the waste concrete surface;

[0046] 2) Crushing and grading the cleaned waste concrete, and then further ball milling the broken waste concrete to obtain particles with a particle size of 0.1-0.2 mm;

[0047] 3) heat-treating the ground particles at 650°C for 1 hour;

[0048] 4) Soak the heat-treated particles in a sodium hydroxide solution with a mass fraction of 20 wt%, and the solid-to-liquid ratio of the particles to the lye is 1:4;

[0049] 5) After soaking, dry to obtain recycled aggregate.

preparation example 3

[0051] The preparation method of recycled aggregate is as follows:

[0052] 1) cleaning the waste concrete surface to remove impurities on the waste concrete surface;

[0053] 2) Crushing and grading the cleaned waste concrete, and then further ball milling the broken waste concrete to obtain particles with a particle size of 0.1-0.2 mm;

[0054] 3) heat-treating the ground particles at 650°C for 1 hour;

[0055] 4) The particles after heat treatment are soaked in the mixed solution of calcium hydroxide and sodium hydroxide, wherein the mass fraction of calcium hydroxide is 20wt%, the mass fraction of sodium hydroxide is 20wt%, the solid-liquid ratio of particles and lye 1:4;

[0056] 5) After soaking, dry to obtain recycled aggregate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com