Comprehensive evaluation method for welding hot crack sensitivity

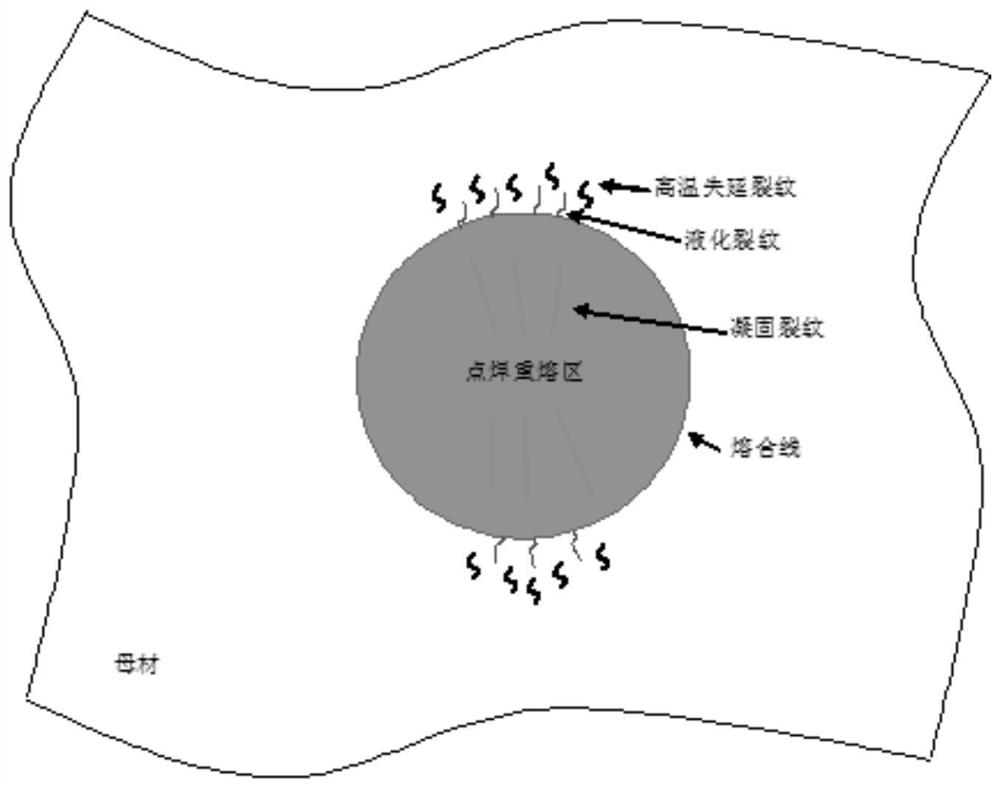

A comprehensive evaluation, hot cracking technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the welding hot crack sensitivity evaluation method cannot be better at the same time evaluate solidification cracks, liquefaction cracks and stalling Cracks and other problems, to achieve the effect of true and reliable test results, easy identification, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, nickel-based alloy material is taken as an example to evaluate its sensitivity to welding hot cracks. The specific method includes the following steps:

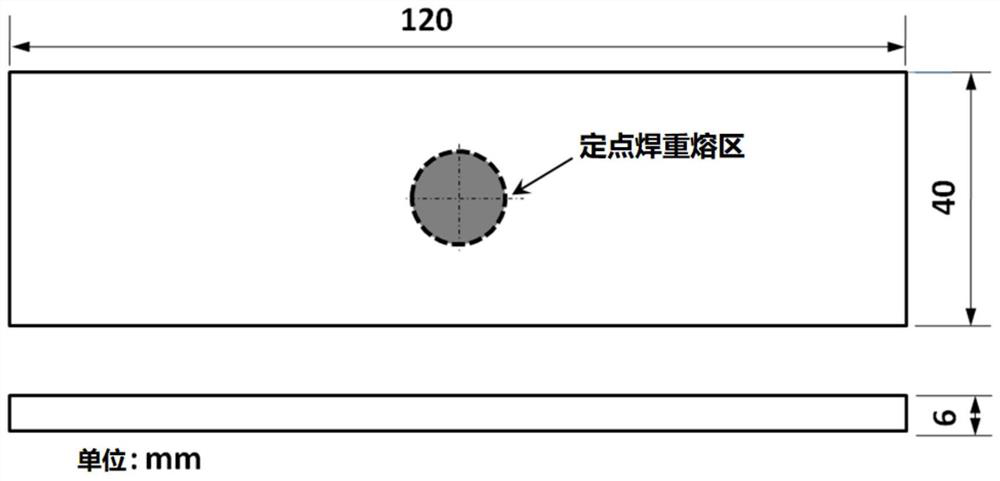

[0032] (1) Taking nickel-based alloys as an example, wire-cutting samples with a size of 120×40×6mm, the number is 8 to 10 pieces, figure 1 A schematic diagram of the sample.

[0033] (2) The surface of the sample is ground step by step with 80-2000 mesh sandpaper, and then the central area with a length and width of 15 mm is polished, and the microstructure is slightly etched with corrosive liquid. Cracks and no obvious scratches.

[0034] (3) Place the sample on a variable restraint testing machine, which is equipped with an argon arc welding power source, and adjust the sample so that the tungsten electrode is facing the center of the sample.

[0035] (4) Use an argon arc welding machine to remelt the center of the sample by arc fixed-point welding. The spot welding current is 80A, the spot wel...

Embodiment 2

[0043] This embodiment takes austenitic stainless steel as an example to evaluate its sensitivity to welding hot cracks. The specific method includes the following steps:

[0044] (1) Wire-cut processing of samples with a size of 150×50×8 mm, the number of which is 8 to 10 pieces.

[0045] (2) The surface of the sample is ground step by step with 80-2000 mesh sandpaper, and then the central area with a length and width of 25 mm is polished, and the microstructure is slightly etched with corrosive liquid. Observe the area under a 500-fold microscope. Cracks and no obvious scratches.

[0046] (3) Place the sample on a variable restraint testing machine, which is equipped with an argon arc welding power source, and adjust the sample so that the tungsten electrode is facing the center of the sample.

[0047](4) Use an argon arc welding machine to remelt the center of the sample by arc fixed-point welding. The spot welding current is 100A, the spot welding voltage is 15V, the spot...

Embodiment 3

[0055] This embodiment takes austenitic stainless steel as an example to evaluate its sensitivity to welding hot cracks. The specific method includes the following steps:

[0056] (1) Wire-cut processing samples with a size of 100×30×4mm, and the number is 8 to 10 pieces.

[0057] (2) The surface of the sample is ground step by step with 80-2000 mesh sandpaper, and then the central area with a length and width of 10 mm is polished, and the microstructure is slightly etched with corrosive liquid, and the area is observed under a 500 times microscope. Cracks and no obvious scratches.

[0058] (3) Place the sample on a variable restraint testing machine, which is equipped with an argon arc welding power source, and adjust the sample so that the tungsten electrode is facing the center of the sample.

[0059] (4) Use an argon arc welding machine to remelt the center of the sample by arc fixed-point welding. The spot welding current is 60A, the spot welding voltage is 8V, the spot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com