Automatic analysis method for shape of deformed long bone

An automatic analysis and deformity technology, applied in the field of medical image processing, can solve problems such as time-consuming errors, reading errors, and inaccurate angle readings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

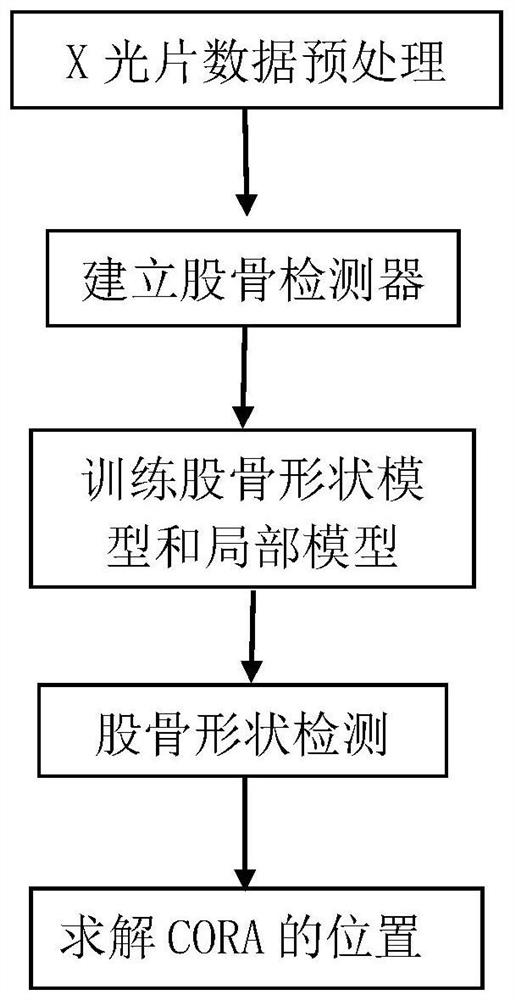

Method used

Image

Examples

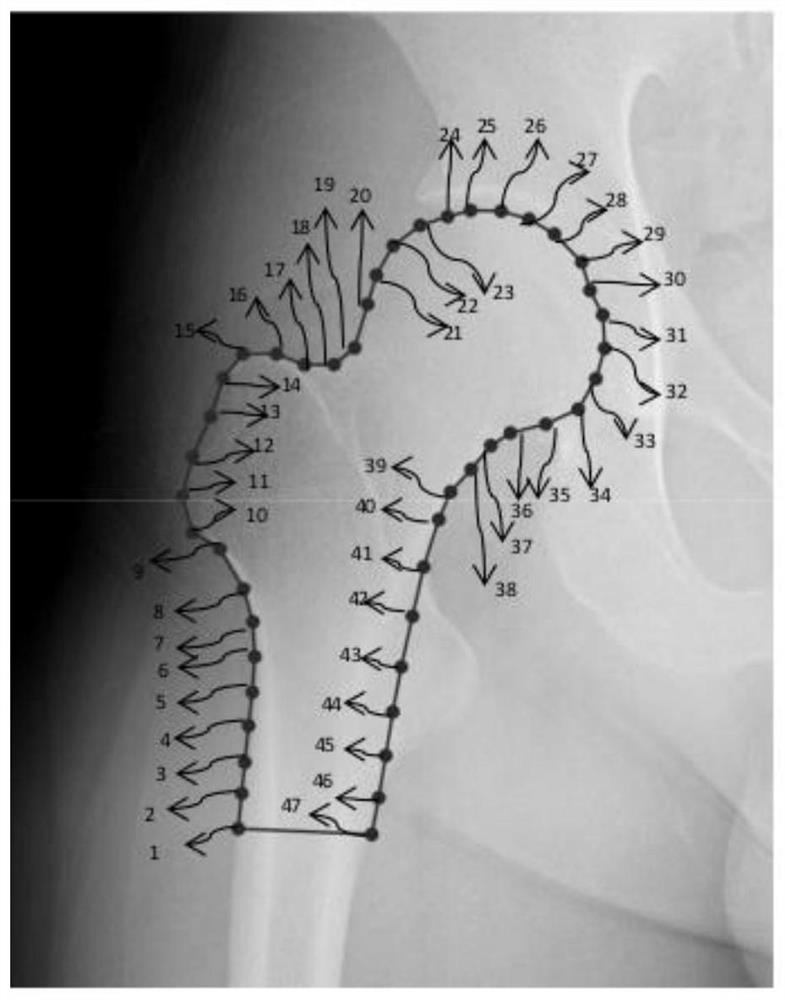

Embodiment 1

[0141] Using the analysis method of the present invention to analyze the shape of deformed long bones, a total of 120 X-ray films of deformed long bones are used, 100 of which are training sets, and the remaining 20 are test sets. Under the guidance of a doctor, the position of the femur and the feature points of the femur are marked manually. First, mark the X-rays in the training set, use a rectangular frame to mark the proximal femur and the distal end of the bone, use 47 points to mark the contour of the proximal femur, and use 49 points to mark the contour of the distal femur, as shown in Figure 2-5 As shown, the points with the same serial number were basically located at the same position of the femur during the marking process. According to the operations of the first step to the fourth step of the analysis method of the present invention, the optimal position of the contour feature point of the proximal end of the femur and the optimal position of the contour feature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com