Preparation method of bud tea extract and application of bud tea extract in essence and electronic cigarette oil

A tea extract and tea extraction technology, which are applied in the field of plant extraction, preparation and application, can solve the problems of lack of reports on the development and utilization of flavors, affecting the sensory evaluation and selection preference of electronic cigarette smoking, and achieve a fresh and natural fruit flavor and low cost. , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

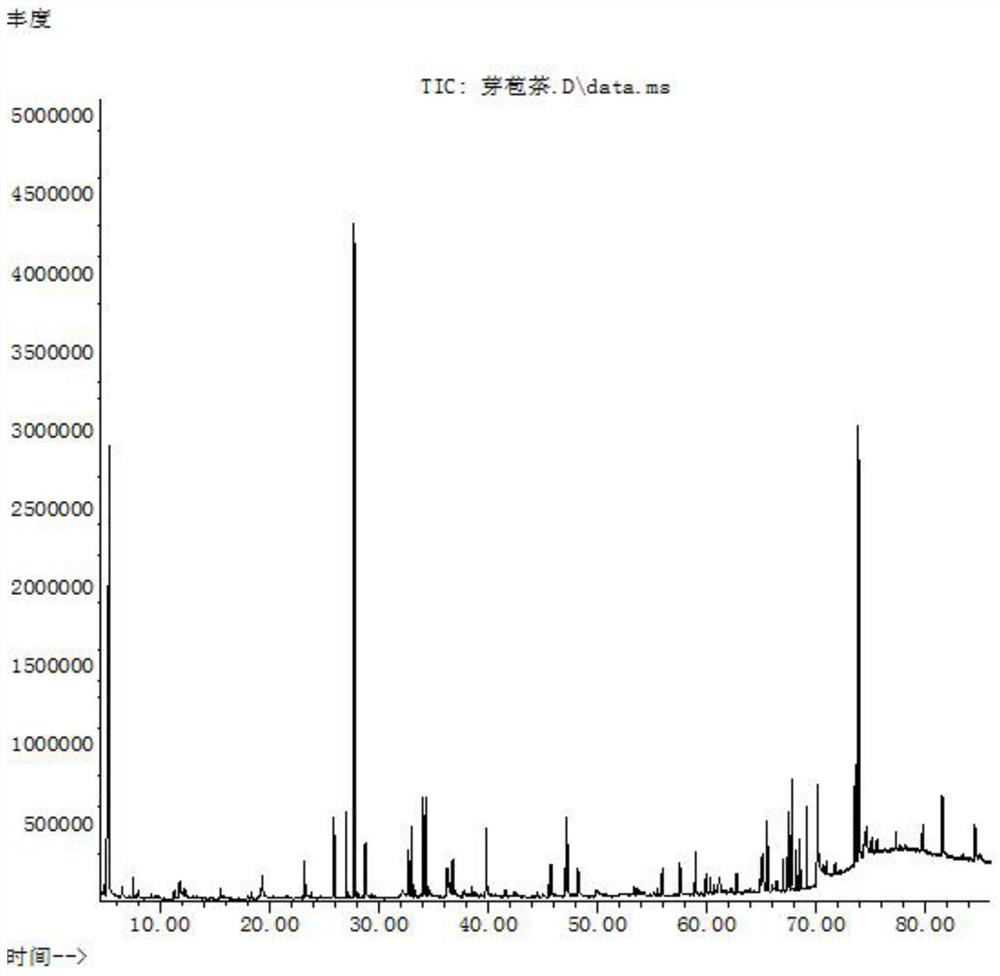

[0021] The preparation method of the bud tea extract of the present invention comprises pulverizing the bud tea into bud tea powder; extracting and separating the bud tea powder using a CO2 fluid supercritical method to obtain the bud tea extract. Conventional extraction method, the present invention uses supercritical CO2 fluid extraction technology combined with low-temperature centrifugation technology to prepare the bud tea extract without caffeine, which is applicable to a wider range of people, retains the natural and fresh aroma of bud tea to the greatest extent, and has no environmental impact. Harmful solvent generation and discharge, green and pollution-free; and the prepared bud tea flavor has high linalool content (>11.2%), low linalool oxide content (<3.9%), and also contains a variety of small molecules Organic acids, such as acetic acid, isobutyric acid, and isovaleric acid, these low-molecular-weight organic acids can increase fruit and cheese-like aromas, incre...

Embodiment 1

[0025] Weigh 500g of bud tea powder and pulverize it to tea powder, add it into the extraction tank of supercritical CO2 fluid extraction with a CO2 flow rate of 1.0L / h, add 50g of 95% ethanol, and extract at an extraction temperature of 35°C, an extraction pressure of 15MPa and a separation temperature Under the conditions of 35° C. and separation pressure of 7 MPa, extraction and separation were carried out for 1.0 hour to obtain 30 g of bud tea extract 1 with an extraction rate of 6%.

Embodiment 2

[0027] Weigh 500g of bud tea powder and pulverize it to tea powder, add it into a 1000mL supercritical CO2 fluid extraction tank with a CO2 flow rate of 1.0L / h, add 50g of 95% ethanol, and extract at an extraction temperature of 40°C, an extraction pressure of 20MPa and a separation temperature Under the conditions of 35° C. and separation pressure of 8 MPa, extraction and separation were carried out for 1.5 hours to obtain 38 g of bud tea extract 2 with an extraction rate of 7.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com