Copper recovery device for waste circuit board

A technology for recycling devices and waste circuit boards, which is applied in the direction of electronic waste recycling, recycling technology, solid waste removal, etc., can solve the problems of reduced work efficiency, heavy workload of staff, and long crushing time, so as to improve work efficiency , less manual operation, and reduce the effect of crushing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

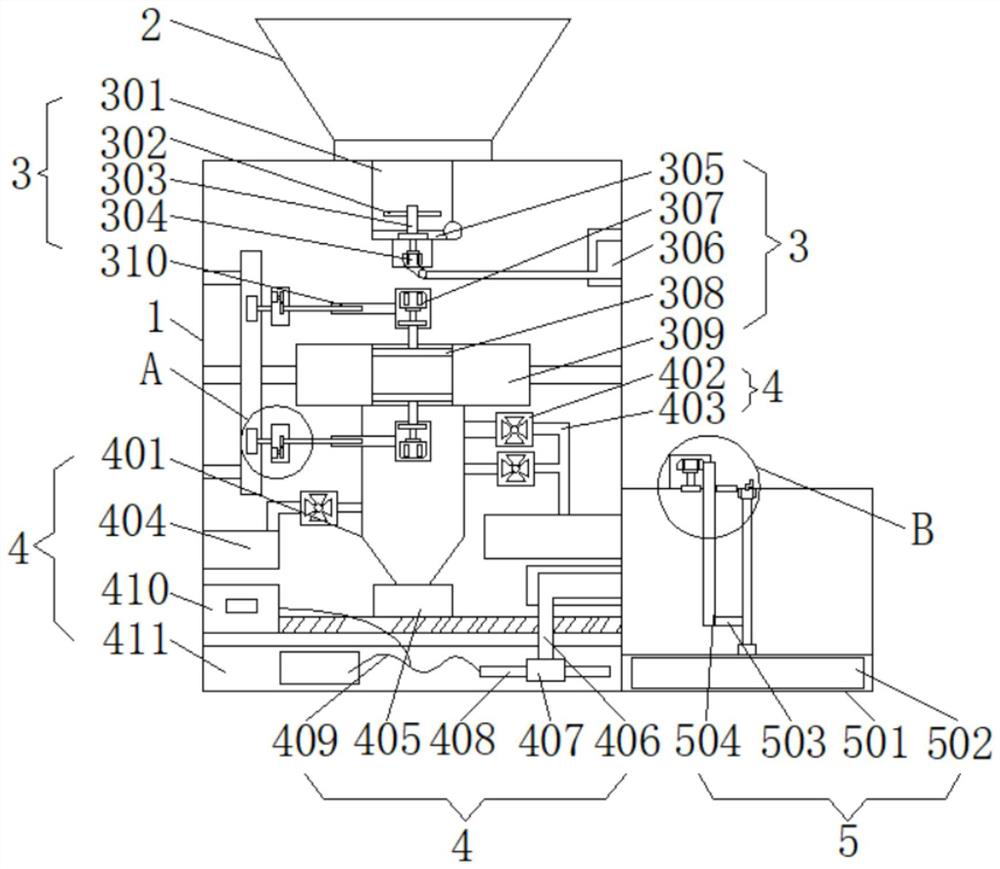

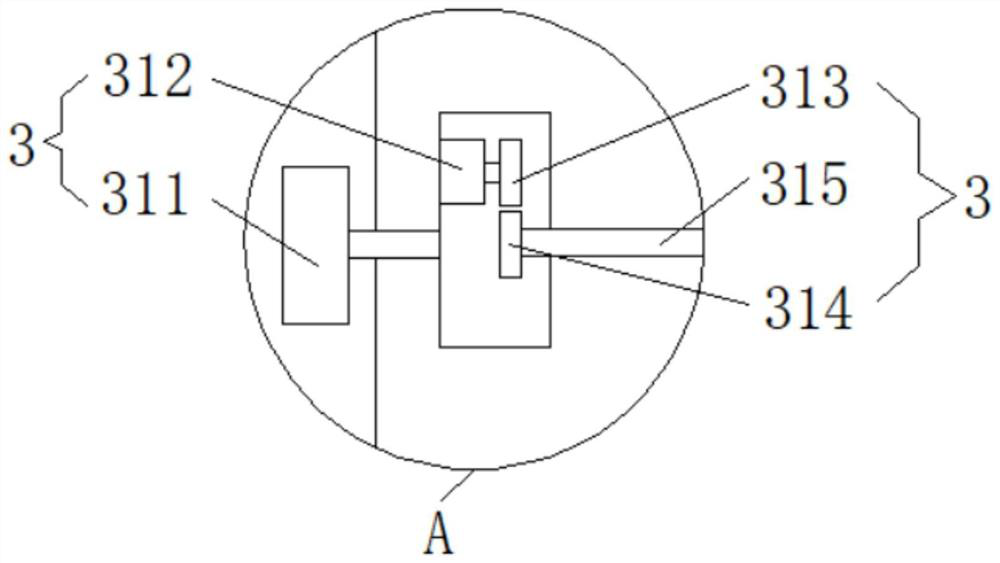

[0029] Such as Figure 1-Figure 4 As shown, the present invention provides a copper recovery device for waste circuit boards, comprising: a body 1, a feed box 2, a crushing mechanism 3, a separation mechanism 4, and a collection mechanism 5. The top of the body 1 is fixedly equipped with a feed box 2, And the bottom of feeding box 2 is fixedly installed crushing mechanism 3, the inside of body 1 is fixedly connected with separation mechanism 4, and the right side of body 1 is fixedly installed with collecting mechanism 5; Wherein, crushing mechanism 3 includes cutting box 301, cutting knife 302 , the first rotating column 303, the first motor 304, the fixed plate 305, the first electric push rod 306, the first driving motor 307, the crushing plate 308, the crushing box 309, the first threaded rod 310, the linear motor 311, the second motor 312, the first gear column 313, the second gear column 314 and the connecting shaft 315.

[0030]Preferably, in one of the preferred techn...

Embodiment 2

[0033] Such as figure 1 As shown, this embodiment provides a copper recovery device for waste circuit boards. The difference from Embodiment 1 is that the separation mechanism 4 includes a delivery pipeline 401, a suction fan 402, a discharge pipe 403, a non-metallic collection box 404, and an anode Bag 405, second electric push rod 406, fixed block 407, graphite block 408, wire 409, power supply box 410 and solution pool 411, and the bottom of crushing box 309 is fixed with delivery pipeline 401.

[0034] Preferably, in one of the preferred technical solutions of this embodiment, suction fans 402 are fixedly installed on the left and right sides of the delivery pipe 401, and the other side of the suction fan 402 is fixedly connected with a discharge pipe 403, and the discharge pipe 403 The other end is fixedly installed with a non-metallic collection box 404, the bottom of the delivery pipe 401 is movably connected with an anode bag 405, and the right side of the anode bag 40...

Embodiment 3

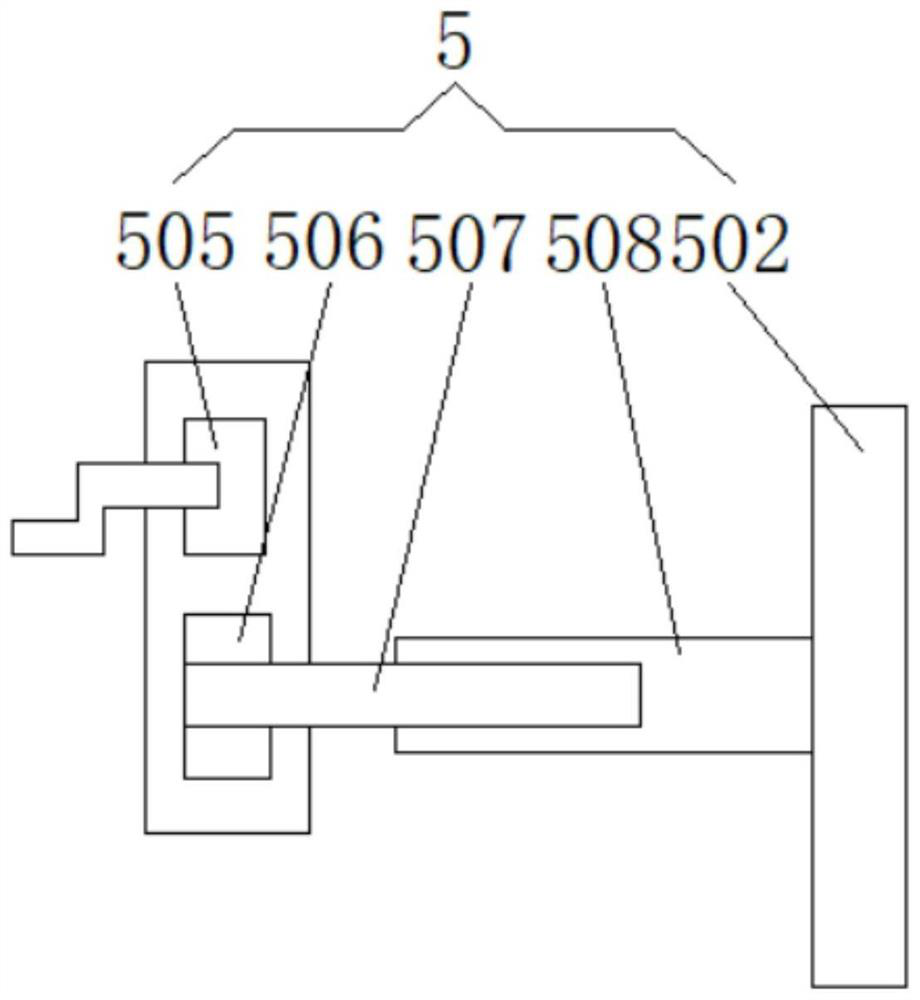

[0037] Such as figure 1 , figure 2 and Figure 4 As shown, the present embodiment provides a copper recovery device for waste circuit boards. The difference from Embodiment 2 is that the collection mechanism 5 includes a pure copper collection box 501, a collection box 502, a scraper 503, a gear bar 504, and a first gear Block 505, second gear block 506, second rotating column 507, second threaded rod 508, second drive motor 509 and third gear block 510, the right side of body 1 is fixed with pure copper collection box 501.

[0038] Preferably, in one of the preferred technical solutions of this embodiment, a collection box 502 is installed movable inside the pure copper collection box 501, and the reverse side of the collection box 502 is fixedly installed with a second threaded rod 508, the second threaded rod 508 The second rotating column 507 is sleeved on the outside, and the other end of the second rotating column 507 is sleeved with a second gear block 506. The right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com