Quick-drying cement-based lightweight base leveling material and preparation method thereof

A cement-based, quick-drying technology, applied in the field of cement-based base leveling materials, can solve the problems of shortening the construction interval, shortening the setting time, fast hardening but not fast drying, etc., and achieves improved density, fast drying, and quality stability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

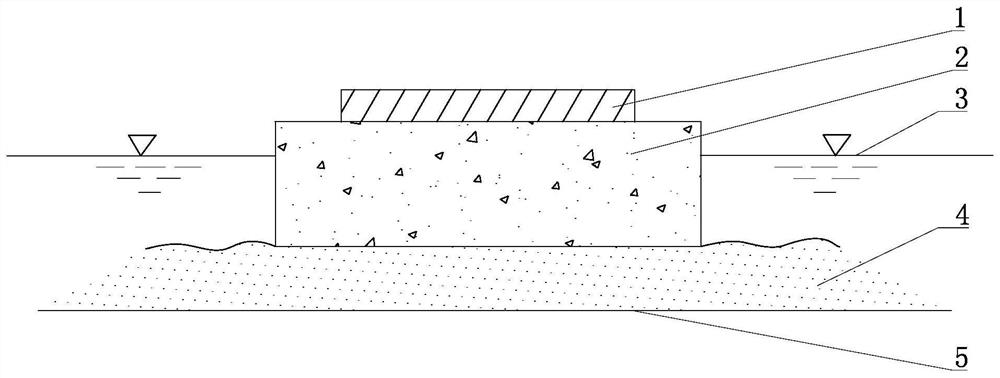

Image

Examples

Embodiment 1

[0052] A preparation method of a quick-drying cement-based light base leveling material, which is prepared by the following steps:

[0053]In the mixer, add cement, light fillers and chemical admixtures according to the proportion of powder components, stir, pre-mix for 10 minutes, then add sand and inert fillers, stir for 20 minutes, and make the raw materials fully mixed, that is, the quick-drying type is obtained. Cement-based light base leveling material.

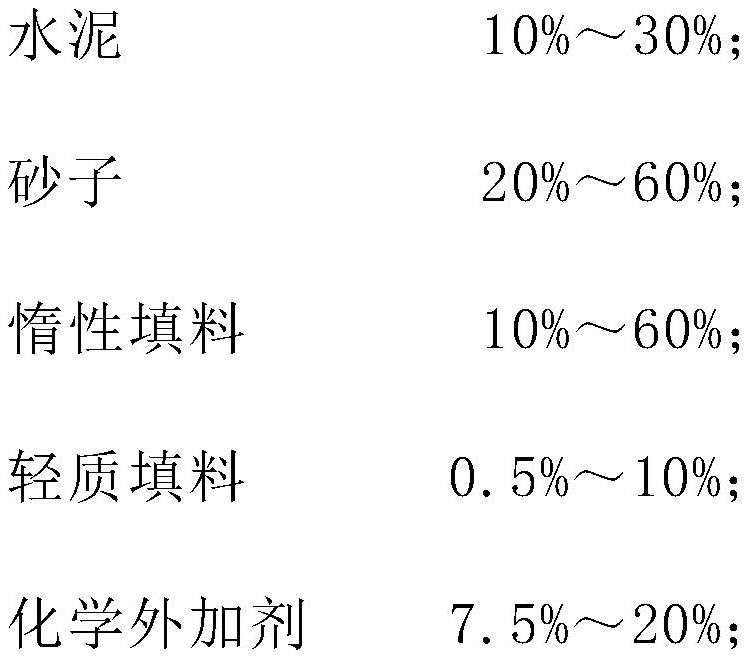

[0054] Wherein the weight percent composition of powder component is shown in Table 1:

[0055] The weight percent composition of table 1 powder component (%)

[0056]

[0057]

[0058] The lightweight filler is regenerated polystyrene particles;

[0059] The chemical admixtures are retarders and quick-hardening agents.

[0060] The weight ratio of the cement, the quick-hardening agent, the retarder and the renewable polystyrene particles is: 1:(0.28-0.31):(0.0025-0.003):(0.03-0.04).

[0061] The cement contai...

Embodiment 2

[0076] This embodiment is a more specific and optimized embodiment.

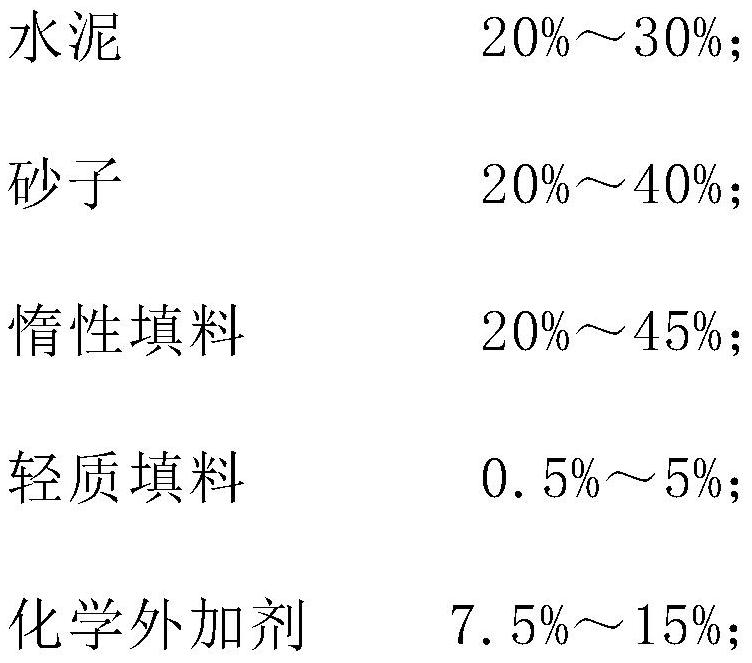

[0077] In the present embodiment, wherein the weight percent of the powder component is composed of:

[0078]

[0079]

[0080] According to the national standard >, the enterprise internal test method <<TU-NPZ-S7.3-WI-006 Nippon Paint Interior Wall Putty Application Test and Evaluation" and "NP-S7-IS" -122 Gypsum Mortar Yellowing Test" and "JG / T 298-2010 Indoor Putty for Construction" to test and evaluate the formula.

Embodiment 3

[0082] This embodiment is a more specific and optimized embodiment.

[0083] In the present embodiment, wherein the weight percent of the powder component is composed of:

[0084]

[0085]

[0086] According to the national standard >, the enterprise internal test method <<TU-NPZ-S7.3-WI-006 Nippon Paint Interior Wall Putty Application Test and Evaluation" and "NP-S7-IS" -122 Gypsum Mortar Yellowing Test" and "JG / T 298-2010 Indoor Putty for Construction" to test and evaluate the formula.

[0087] A general method for measuring the properties of the quick-drying cement-based light base leveling material of the present invention:

[0088] (1) Determination of bulk density

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com