Porous ceramic and preparation method thereof

A technology for porous ceramics and powder, which is applied in the field of porous ceramics and its preparation, achieves the effects of wide source of raw materials, simple process and improved heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

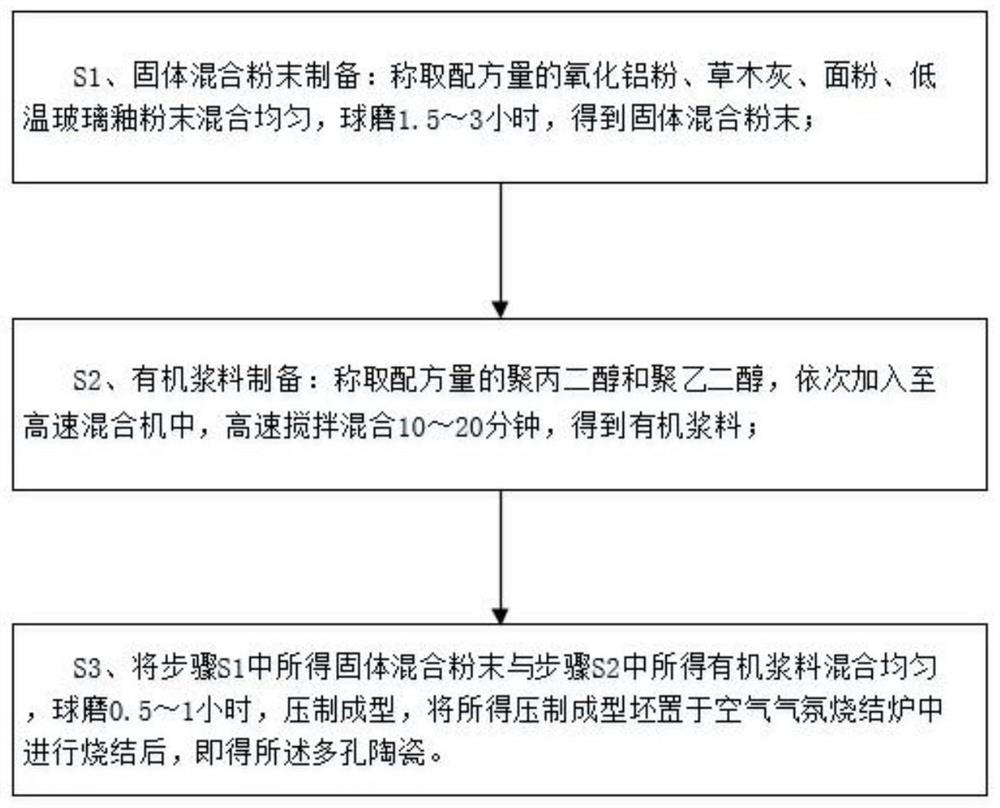

Method used

Image

Examples

Embodiment 1

[0030] A porous ceramic consisting of solid mixed powder and organic slurry, the mass ratio of solid mixed powder to organic slurry is 72:10;

[0031] The solid mixed powder includes raw materials of the following weight: 40g of alumina powder, 6g of plant ash, 6g of flour, and 20g of low-temperature glass glaze powder;

[0032] The organic slurry includes the following raw materials by weight: polypropylene glycol 1 g, polyethylene glycol 5 g.

[0033] Wherein, the flour in this embodiment is commercially available common edible flour.

[0034] Wherein, the mesh number of the alumina powder in this embodiment is 180 mesh.

[0035] Wherein, the molecular weight of the polypropylene glycol in the present embodiment is 2000.

[0036] Wherein, the polyethylene glycol in the present embodiment is 1 g of polyethylene glycol with a molecular weight of 600, 1 g of polyethylene glycol with a molecular weight of 1000, 1 g of polyethylene glycol with a molecular weight of 2000, and 1 ...

Embodiment 2

[0044] A porous ceramic consisting of solid mixed powder and organic slurry, the mass ratio of solid mixed powder to organic slurry is 76:8.1;

[0045] The solid mixed powder includes the following raw materials in weight: 40g of alumina powder, 6g of plant ash, 10g of flour, and 20g of low-temperature glass glaze powder;

[0046] The organic slurry includes the following raw materials by weight: 3 g of polypropylene glycol, 5.1 g of polyethylene glycol.

[0047] Wherein, the flour in this embodiment is commercially available common edible flour.

[0048] Wherein, the mesh number of the alumina powder in this embodiment is 180 mesh.

[0049] Wherein, the molecular weight of the polypropylene glycol in the present embodiment is 1000.

[0050] Wherein, the polyethylene glycol in the present embodiment is 1 g of polyethylene glycol with a molecular weight of 600, 1 g of polyethylene glycol with a molecular weight of 1000, 1 g of polyethylene glycol with a molecular weight of 20...

Embodiment 3

[0058] A porous ceramic consisting of solid mixed powder and organic slurry, the mass ratio of solid mixed powder to organic slurry is 81:8.6;

[0059] The solid mixed powder includes the following raw materials in weight: 40g of alumina powder, 6g of plant ash, 15g of flour, and 20g of low-temperature glass glaze powder;

[0060] The organic slurry includes the following raw materials by weight: polypropylene glycol 3g, polyethylene glycol 5.6g.

[0061] Wherein, the flour in this embodiment is commercially available common edible flour.

[0062] Wherein, the mesh number of the alumina powder in this embodiment is 180 mesh.

[0063] Wherein, the molecular weight of the polypropylene glycol in the present embodiment is 2000.

[0064] Wherein, the polyethylene glycol in the present embodiment is 1.1 g of polyethylene glycol with a molecular weight of 600, 1.2 g of polyethylene glycol with a molecular weight of 1000, 1.2 g of polyethylene glycol with a molecular weight of 2000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com