Synthetic star-line blended solution-polymerized styrene-butadiene rubber and preparation method thereof

A solution-polymerized styrene-butadiene rubber and blending technology, which is applied in the field of polymer synthesis, can solve problems such as difficult promotion and easy deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

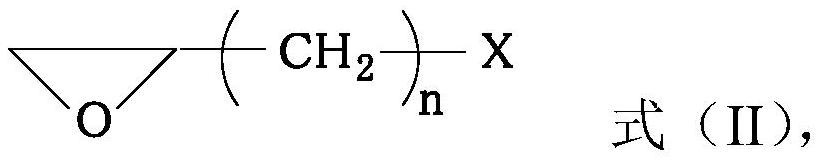

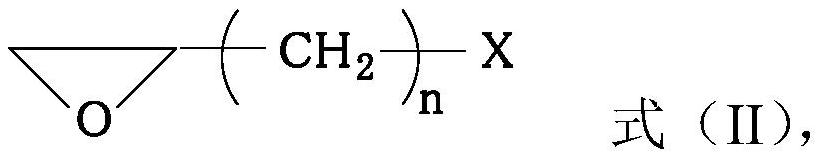

Method used

Image

Examples

specific Embodiment approach

[0041] According to another preferred embodiment, the method further includes: performing a termination reaction on the reaction system obtained after step (2). The present invention is not particularly limited to the specific operation of the termination reaction, and various conventional methods in the art can be used to perform the termination reaction, for example, it can be terminated by introducing an appropriate amount of isopropanol into the system.

[0042] Preferably, the anti-aging agent is selected from at least one of the anti-aging agent 1520, the anti-aging agent 1076, the anti-aging agent 1010 and the anti-aging agent 264.

[0043] According to the present invention, the dosage of the anti-aging agent can be the conventional dosage in this field. For example, based on the weight of the solution-polymerized styrene-butadiene rubber, the amount of the anti-aging agent may be 0.005-2 wt%, preferably 0.1-0.5 wt%.

[0044] According to the present invention, after ...

Embodiment 1

[0058] Under nitrogen protection, add mixed solvent (cyclohexane and normal hexane, weight ratio is 88:12) 2500g, styrene 93g, 1ml ethyl tetrahydrofurfuryl ether, butadiene 280g, The temperature of the system was raised to 45° C., and 20 ml of n-butyl lithium solution was added (the concentration of n-butyl lithium was 0.1437 mol / L). The reaction reached a peak temperature of 98° C. in 8 minutes, and the reaction pressure was 0.35 MPa. After reaching the peak temperature for 5 minutes, the conversion rate reached 100% by sampling and the reaction pressure was 0.25 MPa. After reacting for 15 minutes, add silicon tetrachloride solution 2ml (0.043mol / L) and epichlorohydrin solution in the reactor 10ml (0.072mol / L) to continue the reaction, after 10 minutes of reaction, add 0.5ml isopropanol to terminate. After stirring for 15 minutes, 3.0 g of antioxidant 264 was added.

[0059] After the glue is condensed by water vapor, it is dried by an open mill to obtain a polymerized prod...

Embodiment 2

[0062] Under nitrogen protection, add mixed solvent (cyclohexane and normal hexane, weight ratio is 85:15) 2500g, styrene 73g, 1ml ethyl tetrahydrofurfuryl ether, butadiene 300g, The temperature of the system was raised to 50° C., and 20 ml of n-butyl lithium solution was added (the concentration of n-butyl lithium was 0.1437 mol / L). The reaction reached a peak temperature of 98° C. in 7 minutes, and the reaction pressure was 0.35 MPa. After reaching the peak temperature for 5 minutes, the conversion rate reached 100% by sampling and the reaction pressure was 0.25MPa. After another 15 minutes of reaction, 3.4ml (0.043mol / L) of silicon tetrachloride solution and epichlorohydrin were added in the reactor. Solution 8ml (0.072mol / L) continued to react, and after 10 minutes of reaction, 0.5ml of isopropanol was added to terminate. After stirring for 15 minutes, 3.0 g of antioxidant 264 was added.

[0063] After the glue is condensed by water vapor, it is dried by an open mill to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com