Control device for automatic transmission

A technology for automatic transmissions and control devices, which is applied in transmission control, transmission parts, multi-ratio transmissions, etc. It can solve problems such as oil pump discharge loss, lubricating oil stirring resistance and dragging resistance, and prevent friction coefficient changes. , Suppress shock, suppress the effect of speed change shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Hereinafter, the specific content of the automatic transmission 10 according to the embodiment of the present invention will be described.

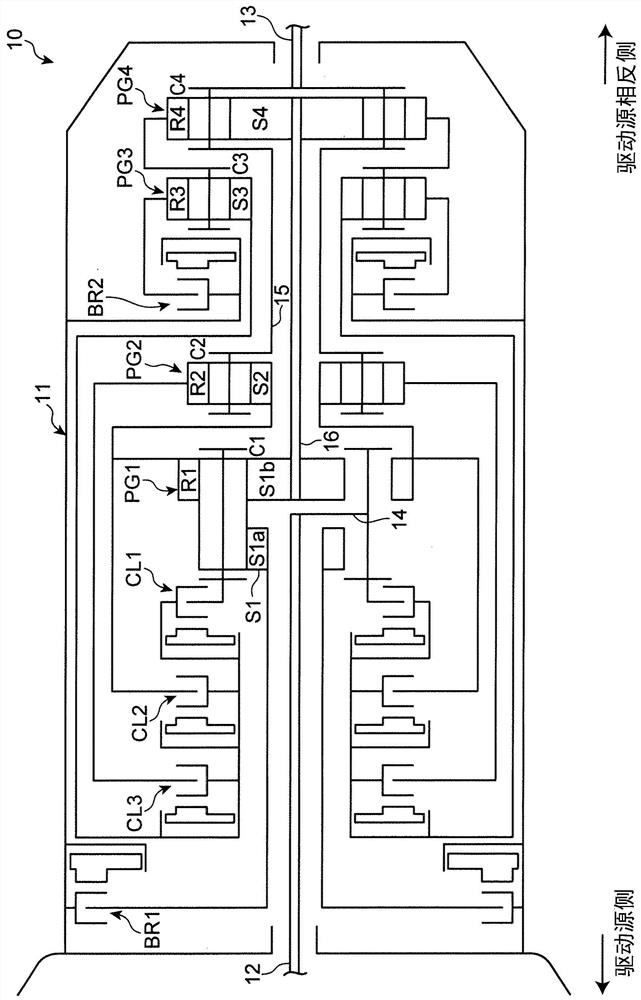

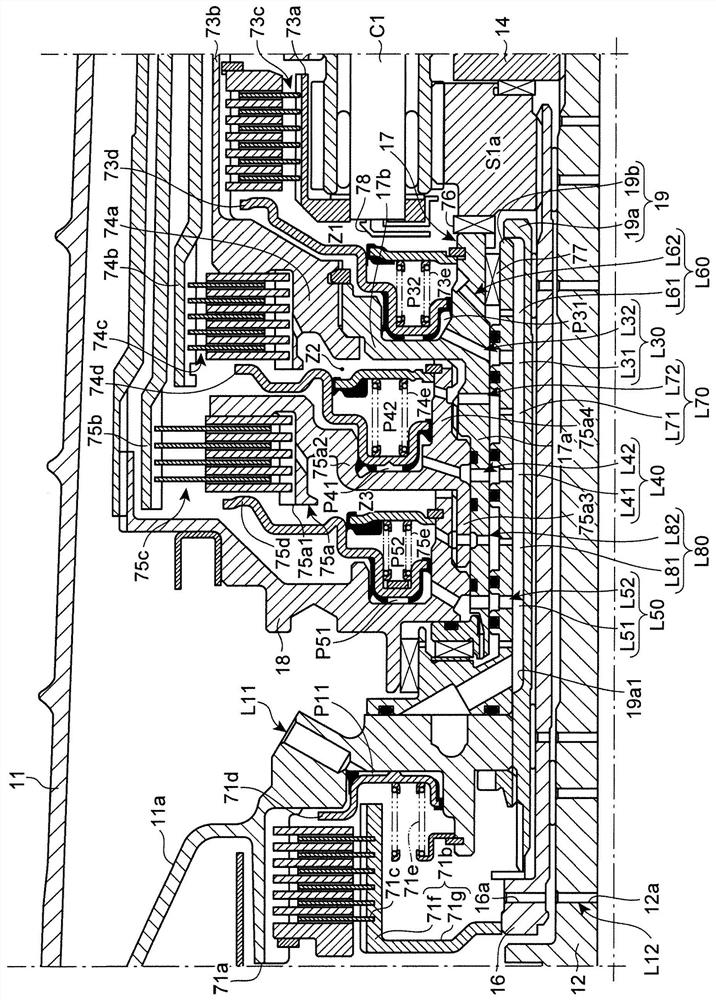

[0058] figure 1 It is a schematic diagram showing the structure of the automatic transmission 10 of this embodiment. The automatic transmission 10 is connected to a driving source such as an engine without passing through a fluid transmission device such as a torque converter. The automatic transmission 10 has an input shaft 12 connected to a driving source and arranged on the driving source side (left side in the figure) and an output shaft 13 arranged on the opposite side of the driving source (right side in the drawing) in a transmission case 11 . The automatic transmission 10 is a vertical type for a front engine rear drive (Front Engine Rear Drive) vehicle in which an input shaft 12 and an output shaft 13 are arranged on the same axis.

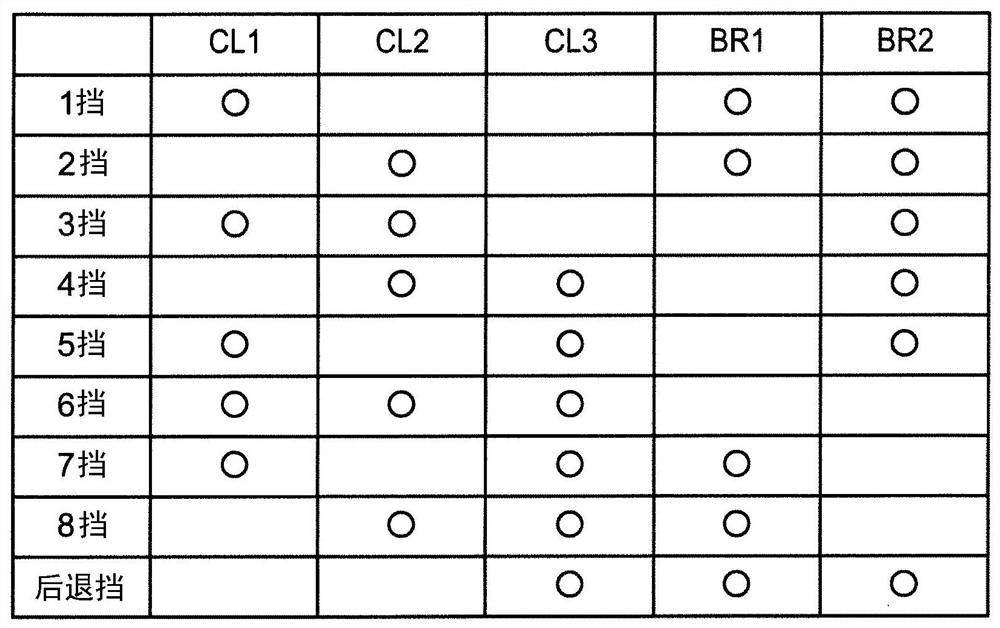

[0059] On the axes of the input shaft 12 and the output shaft 13, the first, second, thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com