Novel magnesium alloy plate material cable bridge

A technology of magnesium alloy plate and cable tray, applied in electrical components and other directions, can solve problems such as environmental pollution and poor corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

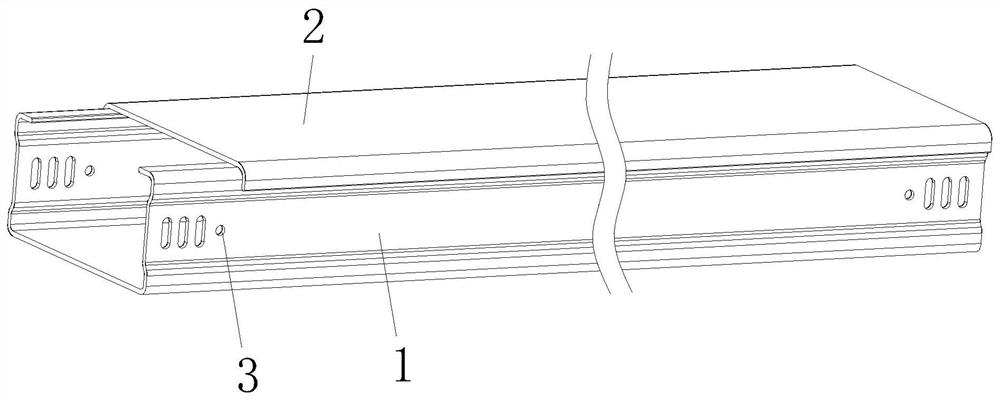

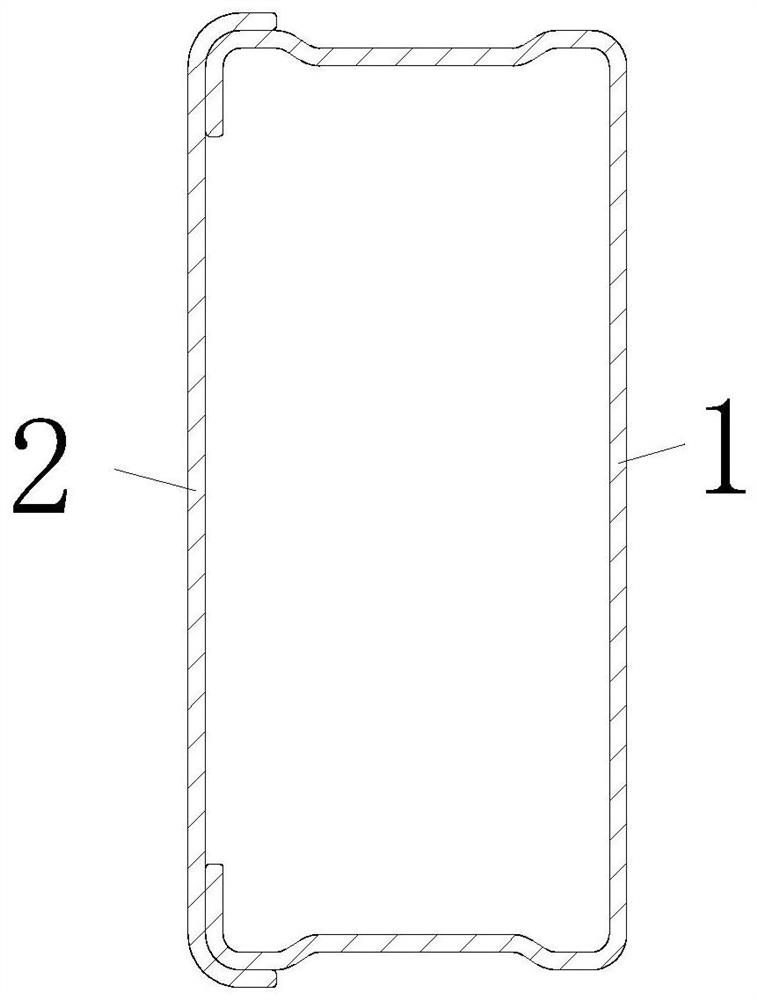

[0028] see Figure 1-2 As shown, the present invention provides the following technical solutions: a novel magnesium alloy plate material cable bridge, comprising a bridge tank box 1 and a bridge tank cover 2, the upper cover of the bridge tank box 1 is equipped with a bridge tank cover 2, the bridge tank box 1 There are connecting bolt holes 3 at both ends of the groove walls on both sides;

[0029] A kind of production method of novel magnesium alloy plate material cable bridge, comprises the following steps:

[0030] S1: Use the uncoiler to unroll the coiled magnesium alloy plate, and transport it to the leveler to level the magnesium alloy plate;

[0031] S2: The magnesium alloy plate after leveling in S1 is transported to the cutting device by a private feeder, cut according to the actual bridge size, and then transported to the punching device for punching, and the bolts at the end of the bridge are processed Holes, and finally the corners of the magnesium alloy sheet ...

Embodiment 2

[0046] see Figure 1-2 As shown, the present invention provides the following technical solutions: a new type of magnesium alloy plate material cable tray, according to the cable tray described in Embodiment 1, when it needs to be used in a fireproof environment, the bridge slot box 1 and the The surface of the bridge tank cover 2 is sprayed with fireproof powder coating. The fireproof coating has excellent flame retardant performance, strong heat insulation performance, excellent fire resistance performance, little environmental pollution, and the fireproof coating has strong adhesion to the bridge matrix and good comprehensive performance. ;Small smell, the fire retardant coating conforms to the standard of GB14907-2002 "General Technical Conditions of Fireproof Coatings for Steel Structures", and the fire resistance limit reaches 3h-3.5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fire resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com